What exactly do you mean? I mix soulutions by volume like 1:2:3 but the solutions themselves are prepared by wieght. All relatively fresh.

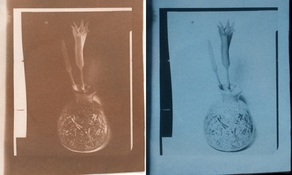

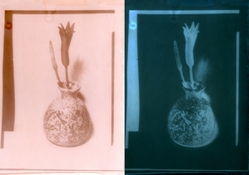

The variation I get is pretty wild. Here is the same paper that I tried during the las couple of weeks. If that's the normal sensitivity of the process to humidity/temperatue/coating then it is unusable and I should give up. But maybe it something else.

I built a special exposure unit for cuprotypes that gives 15 minutes exposure and every time I intend to throw it away I think maybe I should still experiment a bit more.

.View attachment 360494

Never seen such significant variation between test strips processed under identical conditions - unless I deliberately changed the chemistry or processing - within a short span of time. I can't pinpoint what is happening with your process from far so I won't conjecture on what may be happening in your case. I doubt if this process is particularly more or super sensitive to process variables than others out there. @fgorga has printed far more than I with a series of prints, may be he will be able to tell you if this much variation is normal with this process.

The weights I am talking about is first when you prepare each of A, B, and C - my 10% solution for example is 10g of chemical with 90g water. Then when you mix A:B:C by drop counts like 10 drops of A, 15 of B and so on - instead I use 1.0 gram of A, 1.5 g of B, etc. I use squeeze bottles with needle dispensers so the size of a drop is about 0.02g which allows me more accuracy than a glass dropper that is normally used.

:Niranjan.