-

Welcome to Photrio!Registration is fast and free. Join today to unlock search, see fewer ads, and access all forum features.Click here to sign up

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Showcase for Your HCWP's

-

AH

- Thread starter nmp

- Start date

Recent Classifieds

-

For Sale Canon RF 600mm f11, RF 100-400 Lenses

- Started by Jon Shiu

-

For Sale Fujifilm MAXIMA Glossy RA-4 Paper; Packs of 16x20 Sheets

- Started by Aidan Sciortino

-

Sold 1924 Carl Zeiss Jena 150mm f4.5 Lens in dial Compur

- Started by Jon Shiu

-

Found Plastic 5x7 film holders (Fidelity, Lisco)

- Started by blee1996

-

Want to Buy WTB: Digital timer for an enlarger

- Started by Terrence Brennan

Forum statistics

fgorga

Member

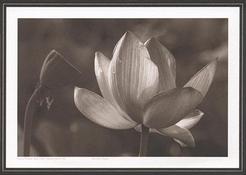

Not sure if this belongs here - technically not a hand coated wet print - but a photopolymer intaglio print from Clay Harmon's workshop .... printed on Hahnemühle etching paper with a mix of black/sienna ink. The interior of a cathedral in Munich ( I can't remember which one). Image captured on a Fuji X-T1, 18-55mm@18/F2.8 - ISO 3200 1/25. Printed on Jet photopolymer plate, UV exposed and developed, hand inked and intaglio printed. Image is about 5X7, scanned on Epson V600. I really like this process; however it requires a rather expensive intaglio press.... even more expensive that the alt photo chemicals/equipment!

Dave

I think it belongs... you did, after all, hand coat the plate with ink... right?

I have a friend (https://www.vaune.net/) who specializes in photopolymer gravure and have watched her make prints. It is a wonderful process.

By the way, your print is quite wonderful as well.

Not sure if this belongs here - technically not a hand coated wet print - but a photopolymer intaglio print from Clay Harmon's workshop .... printed on Hahnemühle etching paper with a mix of black/sienna ink. The interior of a cathedral in Munich ( I can't remember which one). Image captured on a Fuji X-T1, 18-55mm@18/F2.8 - ISO 3200 1/25. Printed on Jet photopolymer plate, UV exposed and developed, hand inked and intaglio printed. Image is about 5X7, scanned on Epson V600. I really like this process; however it requires a rather expensive intaglio press.... even more expensive that the alt photo chemicals/equipment!

Dave

View attachment 346104

Dave, what a stunning image. I am sorry I missed you on your visit here.

- Joined

- Jul 31, 2012

- Messages

- 3,425

- Format

- 35mm RF

Boy, don't come back here for a few days and there is all kinds of good stuff!

Thanks to all for your comments....Sanders, next time I am in Asheville I will look you up. I am pretty sure I will be down for another workshop at Clay's studio - I know he and other alt photo practitioners hold workshops several times a year.

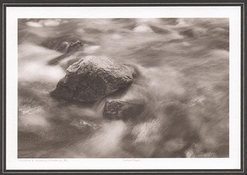

One more - a "chine colle" - printed on gampi paper and laminated on the Hahnemühle etching paper in the press. I need to work on cleaning the edges of the plate ... had a bit of ink on them.. part of the learning process.

One more - a "chine colle" - printed on gampi paper and laminated on the Hahnemühle etching paper in the press. I need to work on cleaning the edges of the plate ... had a bit of ink on them.. part of the learning process.

Sirius Glass

Subscriber

Boy, don't come back here for a few days and there is all kinds of good stuff!

I look multiple times a day, whether or not I need to.

Thanks to all for your comments....Sanders, next time I am in Asheville I will look you up. I am pretty sure I will be down for another workshop at Clay's studio - I know he and other alt photo practitioners hold workshops several times a year.

One more - a "chine colle" - printed on gampi paper and laminated on the Hahnemühle etching paper in the press. I need to work on cleaning the edges of the plate ... had a bit of ink on them.. part of the learning process.

View attachment 346169

Both are exquisite....

Is this using DTP?

Thanks for sharing.

:Niranjan.

Both are exquisite....

Is this using DTP?

Thanks for sharing.

:Niranjan.

Niranjan,

Thank you, they are both DTP (Direct to Plate). Clay has a linearized quadRIP profile set up in his system and we printed on a P900. It is actually pretty straightforward if you have all the equipment at hand (plate, printer, UV box, inking station and press). The only downside is that the plates are moderately expensive ( $16 for an A4) so you don't want to screw too many of them up ( I only wasted one due to some stupidity on my part), however once you have a good plate it can be used to produce many prints.

Dave

Niranjan,

Thank you, they are both DTP (Direct to Plate). Clay has a linearized quadRIP profile set up in his system and we printed on a P900. It is actually pretty straightforward if you have all the equipment at hand (plate, printer, UV box, inking station and press). The only downside is that the plates are moderately expensive ( $16 for an A4) so you don't want to screw too many of them up ( I only wasted one due to some stupidity on my part), however once you have a good plate it can be used to produce many prints.

Dave

Thanks, Dave. For the extra details. It is interesting that it works without having any kind of special receptive coating on the photo-polymer like on an inkjet transparency.

I guess the press is main big-ticket item. Perhaps there is an art school or something like that locally where one can go and rent theirs for a time.

:Niranjan.

fgorga

Member

Thanks, Dave. For the extra details. It is interesting that it works without having any kind of special receptive coating on the photo-polymer like on an inkjet transparency.

I guess the press is main big-ticket item. Perhaps there is an art school or something like that locally where one can go and rent theirs for a time.

:Niranjan.

I am pretty sure the direct-to-plate photo-polymer plates do indeed have a ink receptive layer in addition to a light sensitive layer, etc.

As for access to a press, I would imaging that most cities are likely to have a printmaking studio that is glad to rent time/access to their equipment.

I live in a very rural area and know of three such studios within about two hours drive from me. (To put that in perspective, it is a 20 min drive to a grocery store and a 45 min drive to the nearest 'big box' stores for me.)

A search for "printmaking studio" and a city is likely to get you some leads.

I am pretty sure the direct-to-plate photo-polymer plates do indeed have a ink receptive layer in addition to a light sensitive layer, etc.

You may be right. I didn't know there were separate plates made for DTP. Thought they were just the regular ones adapted for the purpose.

:Niranjan.

fgorga

Member

You may be right. I didn't know there were separate plates made for DTP. Thought they were just the regular ones adapted for the purpose.

:Niranjan.

There are photo-polymer plates which are exposed (contact printed) through a transparency as with most alt processes. (However, if I remember right one uses a positive image not a negative. But don't quote me on that!)

Then there are direct-to-plate photo-polymer plates which allow one to dispense with the transparency. One prints the image directly on the plate and the exposes. The plates are fairly thick and rigid so only some printers (those with a straight feed path option) can be used.

Never done any of this myself. I've just watched my friend do it.

(However, if I remember right one uses a positive image not a negative. But don't quote me on that!)

It's correct though

The way I did it was to laminate a UV-sensitive film onto polyester sheet, expose that through a positive, develop ('etch') the UV resist and then use the plate for intaglio. Due to the limited thickness of the UV sensitive film, which really was intended for PCB manufacturing, the ink-holding capability was limited. But it was sufficient to print images with convincing blacks and decent resolution.

Back then I mostly got into trouble for the lack of a decent point-source UV exposure unit. LEDs weren't around back then, at least not sufficiently powerful and affordable for the purpose, so I made do with UV-BL tubes. The diffuse nature of that light is really unsuitable for this purpose and I had massive problems (in hindsight; I suspected it back then, but wasn't quite sure) with dot gain.

It would be so much easier today, even though this was only a few years ago.

There's still a couple of videos on YouTube where I demonstrate my process. But I've long since sold off the etching press and moved on to other printing processes which I ended up preferring. I still have a soft spot for intaglio, though. It's a beautiful process.

You got to put holes where the ink is going to be so they need to be unexposed - being that the emulsion is negative-acting.It's correct though

I still have a soft spot for intaglio, though. It's a beautiful process.

I am little bit confused about the terminology - how is intaglio different from photogravure?

:Niranjan.

Back then I mostly got into trouble for the lack of a decent point-source UV exposure unit. LEDs weren't around back then, at least not sufficiently powerful and affordable for the purpose, so I made do with UV-BL tubes. The diffuse nature of that light is really unsuitable for this purpose and I had massive problems (in hindsight; I suspected it back then, but wasn't quite sure) with dot gain.

I am NOT a photogravure expert, but I understand from Clay that the UV wavelength needed for DTP exposures is shorter than the wavelength commonly used for other alt processes. I believe Clay said the process requires a 365nm UV light source, and that lights in the 390-400nm spectrum will not work well for DTP plates. Which is too bad since I've already built an exposure box using 390-400nm lights.

how is intaglio different from photogravure?

AFAIK photogravure is a subset within intaglio. The term intaglio refers to the principle of ink being held in depressions in a plate and then being pressed onto/into moist paper. Gravure is an approach to making such depressions, but technically "photogravure" is not a very appropriate term, because it's really more of an etching process than proper gravure. I take it that the 'photo' refers to light being the active agent in doing the 'gravure'.

So it's a bit of a mess, really, the way I see it. In our context, we can get away with mixing up terminology a bit.

I believe Clay said the process requires a 365nm UV light source, and that lights in the 390-400nm spectrum will not work well for DTP plates

400nm works fine for the kind of polymers used these days. Collimation is key, though.

Btw, I used UV BL tubes for my photopolymer work; those peak at around 365nm.

Interesting discussions ... The UV box we used was pretty typical ( 5-6" high and 20X30") - Clay had designed and built it out of aluminum plates, with some fans and a timer built in. I believe he sells them without the UV strips. His was about 400 watts of the 365 nm surface mount LED strips. I believe he bought them from Jon Cone. They were very close spaced. I would not consider it collimated. Exposure time was fairly short 3:30.

We printed a positive on the plate using his P900 with Matte Ink (as I understand, the quadtone RIP profile also printed a very light dot pattern on the light areas as well). He had a clever carrier to hold the plates and we used the front manual feed. We exposed it in the UV burner, washed it out in tap water to produce the relief, and re-exposed it to harden it. The plates were steel backed and were .43mm thick. If you look on Clay's Mountain Intaglio web site he sells the plates and describes their technical specs. Attached is a quick photo of a print and the plate next to it - still partially inked after the printing process.

I would like to determine if I can burn a plates with my 380-400 nm box set up, it is essentially identical to Sanders so I can't claim any credit for the design. I came home with some extra plates so I may give it a try. I am looking into becoming a member ( at least on a short term basis) of the Calliope Arts Printmaking Studio here in Louisville. They seem to have a good array of equipment; several presses and a UV burner - however I don't know if the UV burner will work for polymer plates. If I needed, I could build a new UV box with the 365 nm LEDs and process my plates at my home and just use the studio to make the prints.

I have to admit I am rather taken with this process and will undoubtedly continue to explore it.

Dave

We printed a positive on the plate using his P900 with Matte Ink (as I understand, the quadtone RIP profile also printed a very light dot pattern on the light areas as well). He had a clever carrier to hold the plates and we used the front manual feed. We exposed it in the UV burner, washed it out in tap water to produce the relief, and re-exposed it to harden it. The plates were steel backed and were .43mm thick. If you look on Clay's Mountain Intaglio web site he sells the plates and describes their technical specs. Attached is a quick photo of a print and the plate next to it - still partially inked after the printing process.

I would like to determine if I can burn a plates with my 380-400 nm box set up, it is essentially identical to Sanders so I can't claim any credit for the design. I came home with some extra plates so I may give it a try. I am looking into becoming a member ( at least on a short term basis) of the Calliope Arts Printmaking Studio here in Louisville. They seem to have a good array of equipment; several presses and a UV burner - however I don't know if the UV burner will work for polymer plates. If I needed, I could build a new UV box with the 365 nm LEDs and process my plates at my home and just use the studio to make the prints.

I have to admit I am rather taken with this process and will undoubtedly continue to explore it.

Dave

Perhaps collimation is be less of an issue for DTP as it essentially gives a perfect contact between the "positive" and the photopolymer.

:Niranjan.

:Niranjan.

I came home with some extra plates so I may give it a try.

I will be eager to hear your findings. If koraks is right, and the 380-400nm lights work with your plates, then I might have to jump on this bandwagon.

SMD LEDs give semi-collimated light and this may be good enough for this application as long as the polymer layer isn't too thick. Otherwise undercutting/ foul biting results.

Edit: to clarify, by undercutting, I mean during the exposure, not development/etching (so foul biting is a poor choice of words here). It's easy to understand if you realize that led strips are basicallyany small light sources shining at different angles on each ink dot of the positive transparency. If the light falls perpendicularly on the dot and the underlying plate, the dot will remain nearly unexposed on the plate. But light at various angles will reach the plate underneath the dot due to the thickness of the polymer layer on the plate.

This is the same with carbon transfer. With this process I've done quite extensive work testing various light sources, and I notice that led arrays are still close enough to functioning as a collimated light source to allow e.g. film grain to image reliably on gelatin layers of ca. 100um dry height. This is the same order of magnitudeaher thickness as the polymer film I used back when I was doing photopolymer work.

I imagine that the plates used often today may have thicker polymer layers.nif that's the case, I'd strongly suggest to use a proper (quasi) point source such as a single COB led at a reasonable distance from the plate instead of closely spaced LED strips.

Have a look at Calvin Grier's writings on halftone screen negatives for carbon and gum and the requirements on light sources for this. The same theory applies (and even more so!) to photopolymer.

While LED strips may work, and as argued above I can sort of see how/why, it's a bit of a marginal solution. I'd not recommend it, even though good results are reported by some under certain conditions. Given the availability of better alternatives, I don't see a good reason to risk it. LED strips etc are fine with the common metal-based alt processes with their negligible emulsion thicknesses, but processes like photopolymer are fundamentally different.

The issue is the actual thickness of the polymer layer. Of course, contact needs to be good, too, but a decent contact printing frame will manage that on prints up to 8x10 or even a tad larger.

There are some parallels between intaglio and carbon transfer in this area.

Edit: to clarify, by undercutting, I mean during the exposure, not development/etching (so foul biting is a poor choice of words here). It's easy to understand if you realize that led strips are basicallyany small light sources shining at different angles on each ink dot of the positive transparency. If the light falls perpendicularly on the dot and the underlying plate, the dot will remain nearly unexposed on the plate. But light at various angles will reach the plate underneath the dot due to the thickness of the polymer layer on the plate.

This is the same with carbon transfer. With this process I've done quite extensive work testing various light sources, and I notice that led arrays are still close enough to functioning as a collimated light source to allow e.g. film grain to image reliably on gelatin layers of ca. 100um dry height. This is the same order of magnitudeaher thickness as the polymer film I used back when I was doing photopolymer work.

I imagine that the plates used often today may have thicker polymer layers.nif that's the case, I'd strongly suggest to use a proper (quasi) point source such as a single COB led at a reasonable distance from the plate instead of closely spaced LED strips.

Have a look at Calvin Grier's writings on halftone screen negatives for carbon and gum and the requirements on light sources for this. The same theory applies (and even more so!) to photopolymer.

While LED strips may work, and as argued above I can sort of see how/why, it's a bit of a marginal solution. I'd not recommend it, even though good results are reported by some under certain conditions. Given the availability of better alternatives, I don't see a good reason to risk it. LED strips etc are fine with the common metal-based alt processes with their negligible emulsion thicknesses, but processes like photopolymer are fundamentally different.

Perhaps collimation is be less of an issue for DTP as it essentially gives a perfect contact between the "positive" and the photopolymer.

The issue is the actual thickness of the polymer layer. Of course, contact needs to be good, too, but a decent contact printing frame will manage that on prints up to 8x10 or even a tad larger.

There are some parallels between intaglio and carbon transfer in this area.

Last edited:

fgorga

Member

I am NOT a photogravure expert, but I understand from Clay that the UV wavelength needed for DTP exposures is shorter than the wavelength commonly used for other alt processes. I believe Clay said the process requires a 365nm UV light source, and that lights in the 390-400nm spectrum will not work well for DTP plates. Which is too bad since I've already built an exposure box using 390-400nm lights.

This is my understanding as well.

365 nm UV LEDs are, from what I understand, in a different league from the 400ish nm ones, both in terms of expense and in terms of power requirements. The later requires that 365 nm sources require some serious thought (and expense) with regard to heat sinking and other modes of removing heat. None of this is really necessary with the longer wavelength LEDs.

365 nm UV LEDs are, from what I understand, in a different league from the 400ish nm ones, both in terms of expense and in terms of power requirements. The later requires that 365 nm sources require some serious thought (and expense) with regard to heat sinking and other modes of removing heat. None of this is really necessary with the longer wavelength LEDs.

I'm sorry, but this is not accurate. Let me unpick it a bit.

Expense: 365nm LEDs are more expensive at this point. However, no longer prohibitively so, which is evidenced by the plethora of affordable 365nm fixtures that simply didn't exist in the marketplace 2-3 years ago.

Power: 365nm LEDs have electrical characteristics that are very similar to 400nm LEDs. They have a very slightly higher forward voltage drop at the same current, but the difference is nearly negligible. Any LED driver that will work for 400nm (or blue, or white, or green, or whatever color) will also work just fine with 365nm LEDs of the same power category.

Heatsinking: efficiency of 365nm LEDs is significantly lower than that of longer wavelengths. This means that there's a little more power being dissipated in the form of heat in the semiconductor device itself. So heatsinking requirements will indeed be somewhat more strict, but it's not a world of difference. With cooling/heatsinking, it's wise to use a hefty safety margin anyway, and from that viewpoint, the job and component choice won't be much different from designing a system for 400nm (or white, green, blue etc.) LEDs.

I'd also be very, very cautious with the final phrase in your post: "None of this is really necessary with the longer wavelength LEDs." This is really very tendentious, and if you intended it the way I understand it, it's basically false. Heatsinking and cooling are dependent on device dissipation. In principle there's no relation between emitted wavelength and dissipation. There are plenty of 365m LEDs of low power output that will perform fine with just the limited heatsinking capacity of e.g. a flexible PCB (as in a LED strip). It's also perfectly feasible to take high-power LEDs and run them at significantly lower power levels to reduce the heatsinking requirements. But regardless of color/wavelength, allowing for heat dissipation is true for any LED, and indeed, any semiconductor device. If you take a 10W 620nm red COB LED and let it run for a minute without a heatsink, it'll be toast, just as much as a 10W 365nm unit.

There's nothing 'different league' about 365nm LEDs. What is true, is that the higher the bandgap, the more difficult it is to manufacture a durable, high-power device. The chemistry (but this is your field) is relatively new and as a result, developments proceed at a fairly rapid pace. This pace involves in particular two directions: (1) higher power densities on the same chip/monolithic device, for all wavelengths and (2) higher bandgap materials emitting smaller wavelengths. We see these things happening in the marketplace with high-power LED 'beads' and COB LEDs being common today that were basically impossible to make only a decade ago, and UV LEDs down to the 250nm region that didn't exist a decade ago. It's a gradual push in both directions. The only major leap there was, was back in the 1980s-1990s with the introduction of GaAs-based chemistry that allowed blue LEDs. That one was a major breakthrough and it resulted in a Nobel prize. What we currently see, is mostly variants to that same theme - incremental innovation.

fgorga

Member

I'm sorry, but this is not accurate. Let me unpick it a bit.

Expense: 365nm LEDs are more expensive at this point. However, no longer prohibitively so, which is evidenced by the plethora of affordable 365nm fixtures that simply didn't exist in the marketplace 2-3 years ago.

Power: 365nm LEDs have electrical characteristics that are very similar to 400nm LEDs. They have a very slightly higher forward voltage drop at the same current, but the difference is nearly negligible. Any LED driver that will work for 400nm (or blue, or white, or green, or whatever color) will also work just fine with 365nm LEDs of the same power category.

Heatsinking: efficiency of 365nm LEDs is significantly lower than that of longer wavelengths. This means that there's a little more power being dissipated in the form of heat in the semiconductor device itself. So heatsinking requirements will indeed be somewhat more strict, but it's not a world of difference. With cooling/heatsinking, it's wise to use a hefty safety margin anyway, and from that viewpoint, the job and component choice won't be much different from designing a system for 400nm (or white, green, blue etc.) LEDs.

I'd also be very, very cautious with the final phrase in your post: "None of this is really necessary with the longer wavelength LEDs." This is really very tendentious, and if you intended it the way I understand it, it's basically false. Heatsinking and cooling are dependent on device dissipation. In principle there's no relation between emitted wavelength and dissipation. There are plenty of 365m LEDs of low power output that will perform fine with just the limited heatsinking capacity of e.g. a flexible PCB (as in a LED strip). It's also perfectly feasible to take high-power LEDs and run them at significantly lower power levels to reduce the heatsinking requirements. But regardless of color/wavelength, allowing for heat dissipation is true for any LED, and indeed, any semiconductor device. If you take a 10W 620nm red COB LED and let it run for a minute without a heatsink, it'll be toast, just as much as a 10W 365nm unit.

There's nothing 'different league' about 365nm LEDs. What is true, is that the higher the bandgap, the more difficult it is to manufacture a durable, high-power device. The chemistry (but this is your field) is relatively new and as a result, developments proceed at a fairly rapid pace. This pace involves in particular two directions: (1) higher power densities on the same chip/monolithic device, for all wavelengths and (2) higher bandgap materials emitting smaller wavelengths. We see these things happening in the marketplace with high-power LED 'beads' and COB LEDs being common today that were basically impossible to make only a decade ago, and UV LEDs down to the 250nm region that didn't exist a decade ago. It's a gradual push in both directions. The only major leap there was, was back in the 1980s-1990s with the introduction of GaAs-based chemistry that allowed blue LEDs. That one was a major breakthrough and it resulted in a Nobel prize. What we currently see, is mostly variants to that same theme - incremental innovation.

@koraks

OK... I'll defer to your expertise here. I am certainly no expert on anything electronic that is for sure.

| Photrio.com contains affiliate links to products. We may receive a commission for purchases made through these links. To read our full affiliate disclosure statement please click Here. |

PHOTRIO PARTNERS EQUALLY FUNDING OUR COMMUNITY:  |