Add humectants at the rate of 1 ml or less to each 100 ml of emulsion. You can experiment. You know you have too much when the coating gets tacky.

As for the rod device, AFAIK, no one has gotten things working right with it even having all of the instructions from the Lumiere brothers.

Yes, an alcoholic mixture can hurt things. You must control concentration.

PE

Thanks PE, I'll give that a try.

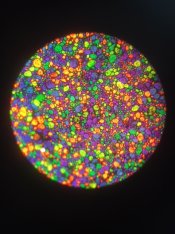

We're in the very dry part of the year. Perhaps low RH is causing the plates to dry too fast.

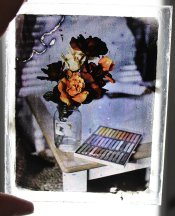

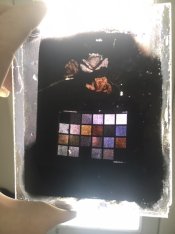

I must admit I was skeptical at first, since this seemed like an issue only with my new batch of screens/emulsion. However, I pulled out one of the plates from my first batch... It had cracked too! Since this seems to be affecting all my plates simultaneously, I'd have to conclude that you're right about dryness being the culprit. And again, there is no starch in the cracks, it seems to be getting 'dragged' with it... Perhaps the second varnish isn't quite as solid as I thought.

In the short term, I'm going to make new emulsion with some humectant and no alcohol and monitor for similar deterioration.

For a slightly longer term, I'm going to start troubleshooting a second varnish that is more in line with the Lumières' original formula. It could be something in the nitrocellulose lacquer throwing things off, possibly just the presence of amyl acetate in the varnish coating even after sitting for weeks. Adding pure nitrocellulose to the ethyl acetate at the rate called for in the original recipe seemed to give the varnish a thick, jell-o like consistency which seemed unsuitable for coating the screens. I'll start with a much smaller quantity of nitrocellulose and see how that does...