I made a little progress in the past week, and got a tiny bit of color response!

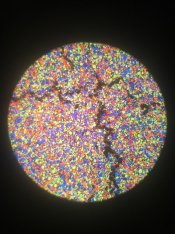

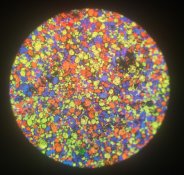

I've managed to get a hold of the original autochrome dyes, and dyed unsorted starch grains accordingly. I may need to modify the recipe slightly, as the green was a bit on the yellow side, giving the screen a heavy yellow cast. Overall though the grains look pretty good.

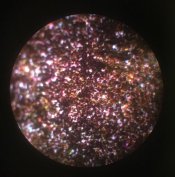

For some reason the second varnish I made is causing 'wrinkles' to appear over the starch, and is lifting the charcoal from the interstitial spaces in between the grains. I found a laquer of just amyl acetate and nitrocellulose sealed the starch better than the original autochrome formulation (though ultimately this was a poor idea, as the photographic emulsion refuses 100% to bind to the nitrocellulose, causing the emulsion to flake off as it dried).

I've found that in most cases there are small holes in the second varnish allowing the starch to get wet during processing. I probably need to work on my coating technique (right now I'm just pouring them collodion style). Over the next week I'm going to remix my second varnish more authentically (no amyl acetate nitrocellulose laquer) and see how it behaves. I might put some more damar resin into the first varnish to see if I can get it stickier, in hopes of it holding on to the charcoal more strongly during second varnish coating.

There was no fog in the emulsion this time. I cleaned all my glassware thoroughly and omitted ammonia from the recipe. I managed to make a panchromatic emulsion with ~1 ISO sensitivity. I'll work on upping the speed when the rest of the kinks are worked out.

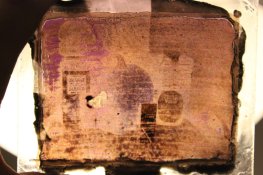

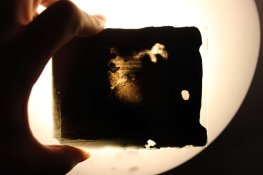

As I only had a single plate in this batch sealed with the second varnish instead of the cellulose laquer, I only had one autochrome to test. I exposed 2 stops longer than the normal glass plate I had poured, though it probably should have been more like 3-4 stops.

After some heavy photoshopping, one can see that I did indeed record color! I think the next immediate goal is to figure out these issues I'm having with the second varnish.... because right now I'm not confident any of these plates could withstand the processing time for a proper reversal processing.

I've managed to get a hold of the original autochrome dyes, and dyed unsorted starch grains accordingly. I may need to modify the recipe slightly, as the green was a bit on the yellow side, giving the screen a heavy yellow cast. Overall though the grains look pretty good.

For some reason the second varnish I made is causing 'wrinkles' to appear over the starch, and is lifting the charcoal from the interstitial spaces in between the grains. I found a laquer of just amyl acetate and nitrocellulose sealed the starch better than the original autochrome formulation (though ultimately this was a poor idea, as the photographic emulsion refuses 100% to bind to the nitrocellulose, causing the emulsion to flake off as it dried).

I've found that in most cases there are small holes in the second varnish allowing the starch to get wet during processing. I probably need to work on my coating technique (right now I'm just pouring them collodion style). Over the next week I'm going to remix my second varnish more authentically (no amyl acetate nitrocellulose laquer) and see how it behaves. I might put some more damar resin into the first varnish to see if I can get it stickier, in hopes of it holding on to the charcoal more strongly during second varnish coating.

There was no fog in the emulsion this time. I cleaned all my glassware thoroughly and omitted ammonia from the recipe. I managed to make a panchromatic emulsion with ~1 ISO sensitivity. I'll work on upping the speed when the rest of the kinks are worked out.

As I only had a single plate in this batch sealed with the second varnish instead of the cellulose laquer, I only had one autochrome to test. I exposed 2 stops longer than the normal glass plate I had poured, though it probably should have been more like 3-4 stops.

After some heavy photoshopping, one can see that I did indeed record color! I think the next immediate goal is to figure out these issues I'm having with the second varnish.... because right now I'm not confident any of these plates could withstand the processing time for a proper reversal processing.