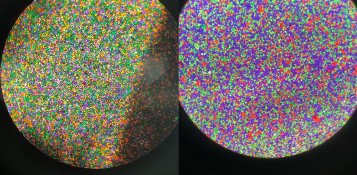

I just was able to take a relaxing break on my vacation to really reflect on these problems. The more I think, the more it seems to me that the first developer's lack of ability to penetrate the emulsion is ultimately at the core of my problems. I think Nodda Duma is right, and what I mistake for overall emulsion contrastiness is actually halation washing out highlight detail.

So let's take a few minutes to analyze the original Lumière formula and compare it to mine, and try to sort out the relative differences. Strap in, because there's going to be a lot of math!

The original Lumière formula is as follows:

Assuming all AgNO3 (~170g/mol) is consumed during precipitation, can assume there are 1.76mols AgX in this emulsion recipe. From this, we can further conclude that there are 5.6mmol of AgX per gram of gelatin.

Applying the same math to my emulsion recipe from earlier this year, we see that mine has only 1.68mmol of AgX per gram of gelatin. We can see that the Lumière recipe had 3.3x as much AgX per weight gelatin than mine, creating a significantly denser coating after drying.

Next, let's try and take a look at how much emulsion should be applied to a 4x5 plate. I emailed Bertrand Lavendrine yesterday, asking if there was a record of how much emulsion was applied per area of the screens, to which he quickly responded "74,4 g/m2 right after gelification".

Bear with me, because the math is probably about to get a bit fuzzy. We need to figure out the rough density of the Lumière emulsion.

The salts added to the emulsion were as follows

3g of KI, or 18.07mmol

240g KBr, or 2016.8mmol

We can say that mols of AgI ocur in the emulsion at a rate of 0.88% of total AgX. Using a weight of 234.77g/mol for AgI and 187g/mol for AgBr, we can say our weights are:

3.67g AgI

327.07g AgBr

For a total weight of 330.7g of AgX in the emulsion.

Finding the rest of the weights should be easy.

6900mL Water = 6900g

315g gelatin = 315g gelatin

Total weight = 7545.7g

Adding them all up, and assuming the volume of the emulsion to still be 6900mL (fuzzy math, know), we get a rough density of 1.09g/mL.

We can now use the rate given to us earlier to find the amount of emulsion that would have been added to a 4x5 screen. 20in^2 = 0.013m^2

Thus, 0.96g would have been applied to a 4x5 plate, and using our fuzzy density, 1.05mL. This is at a gelatin% of 4.5%. It's been stated over and over how thin the autochrome emulsion was, but this is still crazy thin.

If I were to emulate the same AgX:gelatin ratio, while working with a 2.8% wv of gelatin, I would still need to apply a minuscule 1.72mL per screen, roughly 6x less then what I'm applying now.

...

So, what can we learn from this? It seems that, per weight gelatin, the Lumière emulsion had a much higher AgX content. For me to apply roughly the same amount of AgX to a screen, with my recipe I would end up with 3.3 times as much gelatin. I hypothesize that this much gelatin causes the first developer to slowly disperse, ensuring that the AgX on the top of the gelatin (and thus, the AgX that was most likely to experience halation) is developed more readily.

This also explains the result I've noticed, where fairly good color and contrast is achieved when an extremely dilute developer/long dev time is used for first dev, and then a reducer is used after second dev - the dilute developer's action is allowed to work all the way through to the inner gelatin layer, and the reducer eats away at the top (working its way down), thus removing the part of the image receiving the most halation.

So, using these numbers, I can tweak my recipe a bit.

Using the same mmolAgx:gelatin rate, my overall recipe should now contain a maximum of 8.4g of gelatin. The total emulsion volume would be:

I've got a pretty good color balance the rest of my parameters, so I'm just going to tweak my gelatin/water content now and see how that pans out.

Whew... so much for relaxing on vacation...

So let's take a few minutes to analyze the original Lumière formula and compare it to mine, and try to sort out the relative differences. Strap in, because there's going to be a lot of math!

The original Lumière formula is as follows:

| ... | AgNO3 | Water | Gelatin |

| Solution A | 0 | 2500 | 15 |

| Solution B | 300 | 1500 | 0 |

| 1.5L 20%wv gelatin | 0 | 1500 | 300 |

| Additional Water | 0 | 500 | 0 |

| Spectral Sensitizers | 0 | 900 | 0 |

| TOTAL | 300 | 6900 | 315 |

Applying the same math to my emulsion recipe from earlier this year, we see that mine has only 1.68mmol of AgX per gram of gelatin. We can see that the Lumière recipe had 3.3x as much AgX per weight gelatin than mine, creating a significantly denser coating after drying.

Next, let's try and take a look at how much emulsion should be applied to a 4x5 plate. I emailed Bertrand Lavendrine yesterday, asking if there was a record of how much emulsion was applied per area of the screens, to which he quickly responded "74,4 g/m2 right after gelification".

Bear with me, because the math is probably about to get a bit fuzzy. We need to figure out the rough density of the Lumière emulsion.

The salts added to the emulsion were as follows

3g of KI, or 18.07mmol

240g KBr, or 2016.8mmol

We can say that mols of AgI ocur in the emulsion at a rate of 0.88% of total AgX. Using a weight of 234.77g/mol for AgI and 187g/mol for AgBr, we can say our weights are:

3.67g AgI

327.07g AgBr

For a total weight of 330.7g of AgX in the emulsion.

Finding the rest of the weights should be easy.

6900mL Water = 6900g

315g gelatin = 315g gelatin

Total weight = 7545.7g

Adding them all up, and assuming the volume of the emulsion to still be 6900mL (fuzzy math, know), we get a rough density of 1.09g/mL.

We can now use the rate given to us earlier to find the amount of emulsion that would have been added to a 4x5 screen. 20in^2 = 0.013m^2

Thus, 0.96g would have been applied to a 4x5 plate, and using our fuzzy density, 1.05mL. This is at a gelatin% of 4.5%. It's been stated over and over how thin the autochrome emulsion was, but this is still crazy thin.

If I were to emulate the same AgX:gelatin ratio, while working with a 2.8% wv of gelatin, I would still need to apply a minuscule 1.72mL per screen, roughly 6x less then what I'm applying now.

...

So, what can we learn from this? It seems that, per weight gelatin, the Lumière emulsion had a much higher AgX content. For me to apply roughly the same amount of AgX to a screen, with my recipe I would end up with 3.3 times as much gelatin. I hypothesize that this much gelatin causes the first developer to slowly disperse, ensuring that the AgX on the top of the gelatin (and thus, the AgX that was most likely to experience halation) is developed more readily.

This also explains the result I've noticed, where fairly good color and contrast is achieved when an extremely dilute developer/long dev time is used for first dev, and then a reducer is used after second dev - the dilute developer's action is allowed to work all the way through to the inner gelatin layer, and the reducer eats away at the top (working its way down), thus removing the part of the image receiving the most halation.

So, using these numbers, I can tweak my recipe a bit.

Using the same mmolAgx:gelatin rate, my overall recipe should now contain a maximum of 8.4g of gelatin. The total emulsion volume would be:

| %wv | Total mL |

| 2 | 420 |

| 2.8 | 300 |

| 4.5 | 186.66 |

Whew... so much for relaxing on vacation...

Last edited: