WOAH I'M BACK.

Nope. Even if I started sorting the starch and only using the smallest, the silver grains that I'm making are still several orders of magnitude smaller. I can't really offer much of an estimate on the silver grain size... I can barely even see them with the microscope! Fortunate or not, making a silver emulsion with large enough grains to rival the starch seems to be well outside of my current capabilities!

Here's a thought I had the other day:

Currently for first development we use a developer that produces a significant amount of fog to build density within the emulsion (which ultimately gets bleached out).

Instead of doing it during development, could one purposely fog a portion of the emulsion prior to coating - for example, separating 25% of the solution and allowing it to magnetically stir under light for 15 minutes before recombining it with the rest of the emulsion.

This would seemingly come with advantages and disadvantages compared with the current way of doing things.

Pros: Would allow for the use of a more standard developer, like D-76. In turn, this step would be less touchy in terms of getting the timing just right.

Cons: This would affect the whole batch, instead of on a per-plate basis.

Not sure if I'm going to go through with it, but I'm tempted to try it out with that beaker of emulsion that's been sitting around in my fridge for two months.

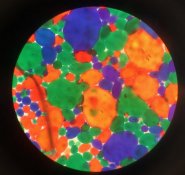

I was just wondering. I read that there are about 4 million starch grains per square cm in historical autochrome. That comes out to about 200 per linear mm depending on the packing.

Do/did you have to go to any particular trouble to make a fine grained emulsion? If the emulsion we're too course many silver halide grains would span more than one filter grains and the result would be much reduced color purity.

Nope. Even if I started sorting the starch and only using the smallest, the silver grains that I'm making are still several orders of magnitude smaller. I can't really offer much of an estimate on the silver grain size... I can barely even see them with the microscope! Fortunate or not, making a silver emulsion with large enough grains to rival the starch seems to be well outside of my current capabilities!

Here's a thought I had the other day:

Currently for first development we use a developer that produces a significant amount of fog to build density within the emulsion (which ultimately gets bleached out).

Instead of doing it during development, could one purposely fog a portion of the emulsion prior to coating - for example, separating 25% of the solution and allowing it to magnetically stir under light for 15 minutes before recombining it with the rest of the emulsion.

This would seemingly come with advantages and disadvantages compared with the current way of doing things.

Pros: Would allow for the use of a more standard developer, like D-76. In turn, this step would be less touchy in terms of getting the timing just right.

Cons: This would affect the whole batch, instead of on a per-plate basis.

Not sure if I'm going to go through with it, but I'm tempted to try it out with that beaker of emulsion that's been sitting around in my fridge for two months.