Michael Mutmansky

Member

Folks,

Over the past almost 40 years of my photography, I don't think I've ever done rotary processing of roll film. I've done the normal inversion tank approach for everything that I can recall and when I did have a Jobo, it was used for sheet film (4x5, and larger using Expert drums). I never used it for roll film processing. Above 8x10 film size, I mostly processed in trays.

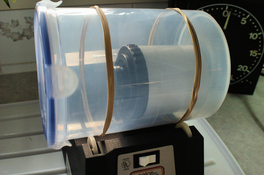

I'm back to shooting film, but only 120, and I've been doing it through the traditional Jobo 1500 series tanks and using inversion processing. That works well, but I'd prefer to automate it some so I can put my attention on getting a new batch of chems ready or for other tasks in the darkroom because I realy have to be more efficient with my time.

As I see it, I have 3 main choices, with some having options within:

The CPE or Filmomat Light allow a water tempering bath which could be very handy for color processing, but I doubt it is really all that necessary for B&W processing. I could just use them without the water, though, but they are a bit more bulky because of that capability.

Next on the list is the Silverbase and all of the Chinese rotary roller units out there. The sad thing is that the Jobo Silverbase is about the sme price as the Filmomat Light, so there's something attractive about just buying that one instead of what appears to be grossly inflated prices for the modern Jobo product. The Chinese products are a lot less expensive, but they are probably nowhere near as robust, so I'm not as incliined to go that route.

I care about the quality of the processing (in this respect, I mean eveneess, not absolute density conrol aspects, ala the Zone System, because I'm scanning after this step, so I don't need to be too precise with the DR of the negatives), and one thing I have seen on occasion with Jobo rotary processing is bromide drag. That never happened with the Expert drums, but I have seen it when there is laminar flow in a drum from the regular rotation. In roll film, I would be concerned more about surge marks from the spools and if the rotary motion back and fourth causes this to be in the same location al the time, it will cause density artifacts.

What I'm interested in is whether I really am better off going the Heiland TAS route for this processing and foregoing the rotary approach because I will get consistentily superior results from keeping an inversion approach for my processing. I see comments/question on here from people who have had problems with roll film in the Jobo but I feel that there isn't enough data to have a clear understanind whether this is an edge case or if it may be more common, especially when looking carefully at the negative with respect to tingls like development uneveness.

I'm looking for some advice/recommendations/experiences for people who have done rotary processing with 120 fim and how that experience compares to inversion, etc.

Many thanks,

---Michael

Over the past almost 40 years of my photography, I don't think I've ever done rotary processing of roll film. I've done the normal inversion tank approach for everything that I can recall and when I did have a Jobo, it was used for sheet film (4x5, and larger using Expert drums). I never used it for roll film processing. Above 8x10 film size, I mostly processed in trays.

I'm back to shooting film, but only 120, and I've been doing it through the traditional Jobo 1500 series tanks and using inversion processing. That works well, but I'd prefer to automate it some so I can put my attention on getting a new batch of chems ready or for other tasks in the darkroom because I realy have to be more efficient with my time.

As I see it, I have 3 main choices, with some having options within:

- Jobo CPE or Filmomat Light

- Jobo Silverbase or similar from China

- Heiland TAS

The CPE or Filmomat Light allow a water tempering bath which could be very handy for color processing, but I doubt it is really all that necessary for B&W processing. I could just use them without the water, though, but they are a bit more bulky because of that capability.

Next on the list is the Silverbase and all of the Chinese rotary roller units out there. The sad thing is that the Jobo Silverbase is about the sme price as the Filmomat Light, so there's something attractive about just buying that one instead of what appears to be grossly inflated prices for the modern Jobo product. The Chinese products are a lot less expensive, but they are probably nowhere near as robust, so I'm not as incliined to go that route.

I care about the quality of the processing (in this respect, I mean eveneess, not absolute density conrol aspects, ala the Zone System, because I'm scanning after this step, so I don't need to be too precise with the DR of the negatives), and one thing I have seen on occasion with Jobo rotary processing is bromide drag. That never happened with the Expert drums, but I have seen it when there is laminar flow in a drum from the regular rotation. In roll film, I would be concerned more about surge marks from the spools and if the rotary motion back and fourth causes this to be in the same location al the time, it will cause density artifacts.

What I'm interested in is whether I really am better off going the Heiland TAS route for this processing and foregoing the rotary approach because I will get consistentily superior results from keeping an inversion approach for my processing. I see comments/question on here from people who have had problems with roll film in the Jobo but I feel that there isn't enough data to have a clear understanind whether this is an edge case or if it may be more common, especially when looking carefully at the negative with respect to tingls like development uneveness.

I'm looking for some advice/recommendations/experiences for people who have done rotary processing with 120 fim and how that experience compares to inversion, etc.

Many thanks,

---Michael