I'm thinking of some ideas that could make this process doable in a home lab. It's strictly theoretical. "Vaporware," if you will:

I have a tabletop reversal tank for movie film. It's called "Morse G3."

It's a large daylight tank with two reels inside used to crank film back and forth, through the developing solutions. There's a window on the side used to let light in for the re-exposure steps. You open the window, shine a light through the portal and crank the film, slowly, past the light stream.

The problem with this tank setup is that it's very hard to get even, predictable development owing to the fact that, most of the time, the film is wound up on reels. The film can't get evenly wet by the chemicals.

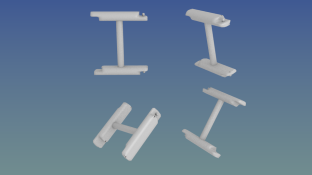

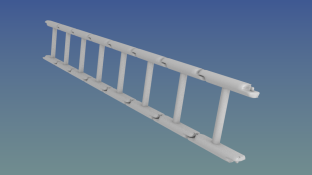

However, if we're developing 35mm rolls of still camera film, we're only talking about lengths of film 1 or 2 meters long. It might be possible to create a labyrinth system of rollers inside the tank that keeps the film submerged in the chemistry at all times. If we splice a piece of Mylar film onto the tail of the roll of film to be developed, we can create a mobius loop. Each time you cycle the film around the "track" it flips over. First the emulsion side of the film faces the window then, on the second lap, the base side of the film faces the window. Just turn the crank and the film is re-exposed in the proper order.

Placing a glass filter over the window ensures the correct color of light exposes the film. On the first lap, the red filter is placed over the window. On the second lap, the blue filter is used. On the third lap, no filter is used.

Let's imagine how this might all come together:

Place the head end of the film into feed roller of the tank. There's already a length of Mylar threaded through the labyrinth system. All you have to do is splice the head of the film to the tail of the Mylar and turn the crank until the film is fed in. At the end, splice the end of the film to the end of the Mylar loop, making sure the film is twisted to create the mobius loop. Close the tank and prepare the chemistry.

Chemistry could be distributed in paper juice boxes. It's pre-measured and ready to use but for mixing. (Which I'll deal with in a moment.)

Temper the juice boxes by submerging in hot water until they are the right temperature. Because paper juice boxes have a little hole in them, used to poke the straw through, we could use that hole to poke in a thermometer. Submerge in hot water and gently shake every few minutes until they are at the right temperature.

When the temperature is right, tear open the spout and pour into a container to mix the "A" and "B" solutions if necessary. No measuring. It's already pre-measured. Just pour and stir.

Put the solutions into the tank and turn the crank to agitate. Open a valve at the bottom and drain out the solution when it's time.

Pour in the next solution or rinse water, crank, time and drain. Repeat with each solution, in turn, as necessary.

When it's time to re-expose the film, place the correct glass filter in the holder and open the port hole. Crank the film past the window at the right speed until all the film has passed the window. Close the portal and continue with the redeveloping solutions.

At this point, the mobius loop will have caused the film to turn over so that the other side faces the window. If all is done right, you should be able to crank the film past the window using the other filter to expose the back side. When done, close the window again and redevelop the second time.

For the third redeveloping step, don't use any filter. Just crank the film past the window with no color and go for the third redevelopment.

Close the window, rinse, fix, condition or what-have-you. When finished, open the tank, take out the film and dry.

A tank for this purpose would probably have to be, maybe, two feet long, a foot wide and at least six inches tall. It would be a fairly large tabletop unit. That gives some room to add some extra gewgaws.

An electronic, digital timer could be built into the top of the unit which is preprogrammed with the times needed for each step. Press the right button to set the preprogrammed time and hit the "start" key. The timer counts down, beeps to remind you when to agitate and beeps continuously when the time is over.

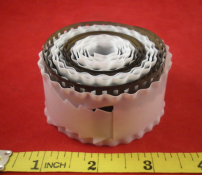

The color filters could be a red, blue and clear glass disk that rotates behind the window. Simply turn the knob to place the right color over the portal.

The Mylar leader could be colored so that you can see it through the window. It could have numbers of symbols printed on it.

At the start of the first round, a number "1" will show through the window. At the end, of the first lap an "1-X" could appear.

For the second round, a "2" and a "2-X" could appear.

A notch could be cut in the edge of the Mylar leader that allows a cam and follower mechanism to warn the user when he has turned the film for a complete lap through the system. The cam could ring a bell, set off an electronic beeper or advance a mechanical counter that lets the user know how far to turn the crank and advance the film.

Theoretically, the whole thing could be motorized or, if an Arduino microprocessor is used, the whole thing could be automated.

If you really wanted to guild the lily, the filling and draining of chemistry could be automated, too.

However, at first, I would shy away from too much automation because it would make the whole thing too expensive.

The main problem I see with this setup is cost. It would be expensive to develop and costly to sell.

I don't know if there is enough undeveloped Kodachrome still left in the world to make this a worthwhile project.

Maybe, if I had thought of this ten years ago, the situation might be different.

However... "Chicken and the egg"...

If somebody could produce these kits at a price people could afford, maybe they'll create enough demand for product that somebody would be able to produce it.

I know, it's wishing in one hand and sh*tting in the other.

P.S. - If anybody ever develops this product and makes it to market, I don't want money. All I want is free product for life.

</tongue-in-cheek>

</tongue-in-cheek>