nick mulder

Member

- Joined

- May 15, 2005

- Messages

- 1,212

- Format

- 8x10 Format

That would be useful. Do you have any pictures of the bellows under construction?

I have made bellows before but I am always interested in other people's methods as I'm sure mine was not the best method.

I have access to sheets of various thicknesses of polyester and polycarbonate with and without adhesive applied and the use of a nice laser cutter to cut out things like stiffeners and I am just about to have a go at making a set of bellows for a Speed Graphic and perhaps another set for something else.

No photos taken - but some facts:

- I did use a form and will continue to do so (recommended)

- I did the gluing 'inside out' as you'll see in some instructions - I've been thinking this might work against things for a couple of reasons, I'll experiment next time with an alternative

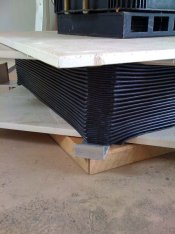

- I used thin 'stiffeners', I find the real work they do is in fact in the areas where they are not, as in the folds, the flat areas are kept flat by the nature of the folds so no need to bulk up here, LF film is fine and 'at home' so to speak

I used what felt like even thinner stuff at ~100um

I used what felt like even thinner stuff at ~100um- I don't draw anything on the leather or inside cotton but a couple of initial registration points, the stiffener registration is formed on the paper model and kept in place by strips of masking tape... a picture is worth a thousand words here (sorry!)

The real money is in getting the geometry into your blood, its a strange hybrid of continuous and discrete maths problems to solve if you get to thinking about it - remembering that once its all perfect on paper there is still a large fudge factor anyway with all the construction slop (especially of the additive kind)... Every change will affect something

I can tell you that there are instructions out there that are just plain wrong - you'll get a bellows, but not quite right ya'know

At the least redundant procedures and some which go about things correctly but use a half way there method explaining it that doesn't help you understand why what needs to happen is happening, and hence no chance to learn how to extrapolate the concepts and have a universal understanding...

At the least redundant procedures and some which go about things correctly but use a half way there method explaining it that doesn't help you understand why what needs to happen is happening, and hence no chance to learn how to extrapolate the concepts and have a universal understanding...I can see that typing up instructions would be almost harder work than the bellows themselves.

Perhaps tell me your process and I can chip in ?

Remember that I still have no idea of the long term prospects of my bellows - I'm interested to see how a bit of use will affect them

)

)

(agree ?)

(agree ?)