Yeap! And did you noticed the objects on the desk, especially the clock?

-

Welcome to Photrio!Registration is fast and free. Join today to unlock search, see fewer ads, and access all forum features.Click here to sign up

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hello APUG from FILM Ferrania

-

A

- Thread starter FILM Ferrania

- Start date

Recent Classifieds

-

For Sale Will Travel 4x10 camera Fujinon SW120mm f8 lens in Copal

- Started by Simon Benton

-

For Sale Sinar Norma / S2 8x10 camera

- Started by Guivd

-

For Sale Mint Nikon D2X Camera Body

- Started by Barlow

-

For Sale Rollei 40mm Sonnar F2.8 LTM

- Started by RoboRepublic

-

For Sale Schneider Kreuznach Super Symmar HM 210mm

- Started by Guivd

Forum statistics

- Status

- Not open for further replies.

Some news from Ferrania:

Dead Link Removed

The big question is... What FILM was this shot on????

Ok, i'll try to caption the pics:

1. Corrado Balestra doing serious stuff

2. Corrado and serious computer. Engineers don't need fancy Graphical User Interfaces.

3. Corrado feeding a roll of 100 meters of fanfold paper to a high-speed printer, hoping to print the whole "Hello APUG from FILM Ferrania" thread.

4. The "Hello APUG from FILM Ferrania" thread printout is placed on a special Jumbo container and cradle

5. Transporting the cradle

6. Idem

7. Idem

8. Cradles ready for printouts of other APUG topics full of off-topic messages and wacky requests for special films and formats.

9. Nice christmas tree and list of APUG users that have requested special stuff

10. Corrado Balestra taking a sample of Secret Compound X

11. Inspecting Secret Compound X

12. Corrado signing autographs

13. Same

14. Sign in italian reads: "ATTENTION: FLAME WARS AHEAD"

...

17. Mauro Viviani with a headache due to attending requests of bringing down the grain of the film to RMS 7.

18. TITANUS - Mystery medium format SLR made by a collaboration between Hasselblad, Mamiya, and Rollei, hidden in Film Ferrania.

19. Sign in italian reads: "Don't touch the materials. Movie and sound, Firenze; FILM Ferrania project"

20. Special beer fridges for the Ferrania team, stocked with PERONI beer.

etc...

1. Corrado Balestra doing serious stuff

2. Corrado and serious computer. Engineers don't need fancy Graphical User Interfaces.

3. Corrado feeding a roll of 100 meters of fanfold paper to a high-speed printer, hoping to print the whole "Hello APUG from FILM Ferrania" thread.

4. The "Hello APUG from FILM Ferrania" thread printout is placed on a special Jumbo container and cradle

5. Transporting the cradle

6. Idem

7. Idem

8. Cradles ready for printouts of other APUG topics full of off-topic messages and wacky requests for special films and formats.

9. Nice christmas tree and list of APUG users that have requested special stuff

10. Corrado Balestra taking a sample of Secret Compound X

11. Inspecting Secret Compound X

12. Corrado signing autographs

13. Same

14. Sign in italian reads: "ATTENTION: FLAME WARS AHEAD"

...

17. Mauro Viviani with a headache due to attending requests of bringing down the grain of the film to RMS 7.

18. TITANUS - Mystery medium format SLR made by a collaboration between Hasselblad, Mamiya, and Rollei, hidden in Film Ferrania.

19. Sign in italian reads: "Don't touch the materials. Movie and sound, Firenze; FILM Ferrania project"

20. Special beer fridges for the Ferrania team, stocked with PERONI beer.

etc...

Nzoomed

Member

- Joined

- Mar 30, 2012

- Messages

- 1,279

- Format

- 35mm

Nice! Did anybody besides me see the rotary dial phone in the background of the photo with slides on a lightbox?

Keep the good news coming, Dave and Film Ferrania!

Yes i saw the phone, in the LRF walkthrough video you can see other dial phones still installed in the building too.

Its like a retro time capsule just the way it was from the 1960's!

Question for Dave, how old is the big boy building/coater?

I take it that it was built well before the LRF was built, but expect that it was upgraded at some point after 3M purchased Ferrania?

Was there any other research facility before the LRF was built? They must have had another coater for testing products, or were they having to test everything with the big boy coater?

Anyway, im looking forward to seeing more photos from inside big boy as it gets dismantled!

Dave, just one question from me. I believe I asked you about whether Ferrania will be improving the granularity of the 100iso e6 film and you mentioned that this will be the first improvement. Perhaps you could enlighten us perhaps by asking the talented chemists in Italy how one exactly goes about this process? I imagine with the original formula the granularity would be 'set' into the emulsion. I would love to know how hard the task is to reengineer an emulsion from an rms of 13 to one to rival astia 100f (rms7). Thanks!

It's very difficult to answer questions like this, to be honest.

Yes, there will be improvements to our inherited formulae, including in this first batch. I know that granularity is among the issues they would like to address on an ongoing and, most likely, incremental basis.

The processes by which these changes are implemented may or may not be shared - but either way, sharing won't happen until after changes are made, repeated, quantified, etc., and able to be published.

Question for Dave, how old is the big boy building/coater? I take it that it was built well before the LRF was built, but expect that it was upgraded at some point after 3M purchased Ferrania?

Best I can recall, it was originally built in the mid-40s and upgraded in the 80s.

Was there any other research facility before the LRF was built? They must have had another coater for testing products, or were they having to test everything with the big boy coater?

There were always labs to create theoretical products - but before 3M built the LRF, everything had to be tested on Big Boy.

Big Boy wasn't as big back then, but it still required taking general production offline for a few days while multiple experiments were run. Then Big Boy had to be cleaned and reset and reloaded. It was highly inefficient and very wasteful.

Ok, i'll try to caption the pics:

LOVE your captions Flavio!

Nzoomed

Member

- Joined

- Mar 30, 2012

- Messages

- 1,279

- Format

- 35mm

It's very difficult to answer questions like this, to be honest.

Yes, there will be improvements to our inherited formulae, including in this first batch. I know that granularity is among the issues they would like to address on an ongoing and, most likely, incremental basis.

The processes by which these changes are implemented may or may not be shared - but either way, sharing won't happen until after changes are made, repeated, quantified, etc., and able to be published.

No doubt any processes you use to improve grain will be a trade secret! lol

But anyway, for the time being, the grain doesnt look as bad as other films with a grain of RMS13 if the photos ive seen on scotch chrome on Flickr are anything to judge by.

Of course, for any film its good to reduce the grain as much as possible. I trust in due course your engineers will improve this film over time.

People rave and love Tri-X, and Tri-X has a grain of RMS 17... far higher than 13.

Plus-X had a grain of RMS 11 or 12 if i recall correctly. Of course if you use developers such as Rodinal, grain will measure higher.

So i'd say RMS 13 is still OK.

PS: Thanks Dave, i liked the pics and the story of Ferrania posted in the website (i actually would have liked it to be even more detailed... perhaps i'm too much of a nerd). Any update on the site is good news to me!

Plus-X had a grain of RMS 11 or 12 if i recall correctly. Of course if you use developers such as Rodinal, grain will measure higher.

So i'd say RMS 13 is still OK.

PS: Thanks Dave, i liked the pics and the story of Ferrania posted in the website (i actually would have liked it to be even more detailed... perhaps i'm too much of a nerd). Any update on the site is good news to me!

Last edited by a moderator:

I really hope that one day you will start production of APS film. So far it's still possible to buy it on eBay but one day the stores will run out...

Hi Dave, Any possibility of a Minox format? I know that you have the capability of nearly every format, but was wondering if Ferrania could go this small.

I don't use colour film at all, but I am really happy to see this. I have been following from the sidelines. I watched all the videos (it's like porn for me) and looked at all the photos on their FB page. If Ferannia is successful, it would be nice to see if they could tackle a 4x5 B/W IR film ... a "real" IR film, like the old Kodak stuff I used to use.

There's something new in store:

Dead Link Removed

Now Nzoomed can wear Ferraniacolor.

Dead Link Removed

Now Nzoomed can wear Ferraniacolor.

Nzoomed

Member

- Joined

- Mar 30, 2012

- Messages

- 1,279

- Format

- 35mm

There's something new in store:

Dead Link Removed

Now Nzoomed can wear Ferraniacolor.

Now if they will ask me "Do you want film with that?" and i will buy one now!

lol

I hope they add film to the store soon.

Nzoomed

Member

- Joined

- Mar 30, 2012

- Messages

- 1,279

- Format

- 35mm

I had another question for Dave.

If the Modified LRF coater cant meet future demands for production, what other options do you have for building a second coating machine?

Can the coating heads and remaining drying tunnel from big boy be modified to make a smaller coater in the future if the need arose?

I know you mentioned earlier that this is a good problem to have if you need to expand production. From what i understand, its just the part of the drying tunnel from big boy that is being taken?

If the Modified LRF coater cant meet future demands for production, what other options do you have for building a second coating machine?

Can the coating heads and remaining drying tunnel from big boy be modified to make a smaller coater in the future if the need arose?

I know you mentioned earlier that this is a good problem to have if you need to expand production. From what i understand, its just the part of the drying tunnel from big boy that is being taken?

I had another question for Dave.

If the Modified LRF coater cant meet future demands for production, what other options do you have for building a second coating machine?

Can the coating heads and remaining drying tunnel from big boy be modified to make a smaller coater in the future if the need arose?

I know you mentioned earlier that this is a good problem to have if you need to expand production. From what i understand, its just the part of the drying tunnel from big boy that is being taken?

I know you're just looking out for us, but let's not try to think of every problem we could potentially have - because that list is pretty much endless.

If we max out production capacity based on our current plans (as I like to say, "a problem we would love to have"), then we will certainly have the necessary revenue and value to commission some new machinery and maybe a new building or two.

The problem with the "shortage" of Film manufacturing equipment is not that it is impossible to build new machinery, it is that it is very hard to have a business plan to amortize a new machine over expected production. Of course when machines from a closed plant can be purchased for their Scrap value like the Current situation, that equation is much more favourable. The original investors have already lost their shirts on the machinery.

Folks like FILMferrania have a real gift being given to them by the failure of the previous firm to maintain production and in effect writing off the entire plant. They will have to walk a VERY fine line to turn this gift into a viable business, They will Have to keep their Stick on the ice, but we are alll pulling for them.

Folks like FILMferrania have a real gift being given to them by the failure of the previous firm to maintain production and in effect writing off the entire plant. They will have to walk a VERY fine line to turn this gift into a viable business, They will Have to keep their Stick on the ice, but we are alll pulling for them.

I know you're just looking out for us, but let's not try to think of every problem we could potentially have - because that list is pretty much endless.

If we max out production capacity based on our current plans (as I like to say, "a problem we would love to have"), then we will certainly have the necessary revenue and value to commission some new machinery and maybe a new building or two.

Right. ISO 100, 400, and 800/3200 E-6 please.

Go Ferrania!

I'm still wondering if it would be possible to do something about the APS film... Like manufacturing it in rolls for the customer to cut and insert into the cartridges by himself?

Nzoomed

Member

- Joined

- Mar 30, 2012

- Messages

- 1,279

- Format

- 35mm

I'm still wondering if it would be possible to do something about the APS film... Like manufacturing it in rolls for the customer to cut and insert into the cartridges by himself?

APS did interest me for a while, although i always thought it was 35mm wide, but infact its actually only around 24mm wide i read, so the frame size is much smaller.

Anyway, it was a nifty film but im unsure how it would work if it could be loaded from bulk rolls?

Doesnt the camera read the barcodes and/or magnetic strip on the film to register each frame properly?

If so, you couldnt just put a strip cut down from a master roll into an APS cartridge without having issues.

Dave may be able to shed more light on this, but from a technical standpoint, it is an alot more advanced format than other films, i know that Dave mentioned here earlier that he was unsure if they have the conversion equipment, he probably will give us an update on this once he finds out from the team in Italy.

I'm still wondering if it would be possible to do something about the APS film... Like manufacturing it in rolls for the customer to cut and insert into the cartridges by himself?

APS is currently in the "probably not" category for a variety of reasons.

Dave may be able to shed more light on this, but from a technical standpoint, it is an alot more advanced format than other films, i know that Dave mentioned here earlier that he was unsure if they have the conversion equipment, he probably will give us an update on this once he finds out from the team in Italy.

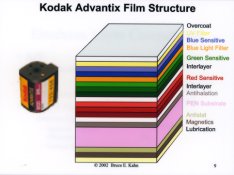

APS film requires a magnetic layer on top of the film, so certain advanced APS cameras (yes, i know, "advanced advanced photo system cameras"

) would record things like exposure information on the film itself, via digital magnetic data recording. This info would then be read by the minilab system.

) would record things like exposure information on the film itself, via digital magnetic data recording. This info would then be read by the minilab system. This is what APS called "IX" (Information eXchange)

So not so easy, to be honest...

But if Ferrania has made APS film in the past, then perhaps they have the equipment.

APS film requires a magnetic layer on top of the film, so certain advanced APS cameras (yes, i know, "advanced advanced photo system cameras") would record things like exposure information on the film itself, via digital magnetic data recording. This info would then be read by the minilab system.

This is what APS called "IX" (Information eXchange)

So not so easy, to be honest...

But if Ferrania has made APS film in the past, then perhaps they have the equipment.

Here is the structure. The magnetic layer is on the bottom.

My thanks to Bruce Kahn for the image and permission to use it. Ok, I still owe you lunch!

PE

Attachments

- Status

- Not open for further replies.

| Photrio.com contains affiliate links to products. We may receive a commission for purchases made through these links. To read our full affiliate disclosure statement please click Here. |

PHOTRIO PARTNERS EQUALLY FUNDING OUR COMMUNITY:  |