The concept could quite easily be transposed to any enlarger, but it would require mechanical adaptations obviously to make the light source fit. I have no plans to make this into a commercial product; it would simply cost too much time to make it work as a consumer product (plus offering after sales support and whathaveyou) and the result would likely be something in the price range of the Heiland product. Therefore I intend to keep it as a one off solution for my specific situation, while sharing the design details as required for those who consider doing something similar. At least it may save them some time figuring some of the stuff out that I had to piece together through study and experimentation.

-

Welcome to Photrio!Registration is fast and free. Join today to unlock search, see fewer ads, and access all forum features.Click here to sign up

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Craziness - using LEDs to print RA4 (and B&W)

-

A

- Thread starter koraks

- Start date

Recent Classifieds

-

For Sale Four H&Y Magnetic 4" Filter Holders and Four Cokin B&W Contrast Filters

- Started by Steve Goldstein

-

For Sale Schneider Kreuznach Super-Angulon 165mm - 8x10

- Started by Guivd

-

For Sale 28mm F2.8 Zuiko for Olympus OM SLR - Excellent Condition

- Started by davela

-

For Sale Nikon Coolscan 8000/9000 film holders - FH-869G, FH-869S, FH-835M

- Started by radialMelt

-

For Sale Mamiya 6 medium format rangefinder - late model, body only

- Started by radialMelt

Forum statistics

There's a bazillion Beseler enlargers out there. None of the Beseler colorheads are really truly reliable.

What goes wrong with the Beseler colour heads? I only use De Vere at the moment, although have used Durst, LPL, and Meopta at various times, not sure I've ever seen a Beseler, although they are available in the UK.

The electronics. The Dichro 45S has a opto-coupler that fails, it's easy to fix, if you have a part. The Beseler Universal 45 head is amazing, closed loop, RGB, dual controllers one for VC one for color. These heads have bugs, are impossible to reliably fix. I have 4 of these 2 work.What goes wrong with the Beseler colour heads? I only use De Vere at the moment, although have used Durst, LPL, and Meopta at various times, not sure I've ever seen a Beseler, although they are available in the UK.

My De Vere 5108 has a simple colour head.

Last edited by a moderator:

OK, a little follow-up on this. I ran into some weird consistency problems with color shifts between consecutive prints. Took me some time to figure out what was going on, but I think I got it. The problem is indeed related to thermal stability.So impressive. And informative.

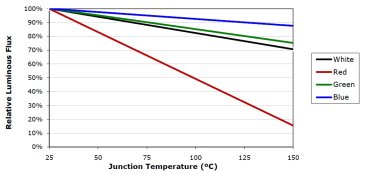

A small comment, meant to be constructive: what about the temperature transients and associated light output changes? The first random power LED datasheet I look up https://www.lumileds.com/uploads/639/DS174-pdf indicates roughly 5% (about 1/15 of f-stop) light output drop (at constant current) for 30°C junction temp rise. Just nominal numbers, of course; only you know the thermal resistance and time constant of your heat sink.

With LEDs, there are two things at play that spoil the broth, as it turns out:

1: As junction temperature rises, light output drops. This is a non-linear relationship and may likely (or perhaps definitely) be different for various types of junctions (i.e. it will be different for the different colors).

2: As junction temperature rises, the dominant wavelength (i.e. color) shifts towards longer wavelengths ('red-shift'). This happens at something like 0.1nm/K, so a 10 degree (C/K) temperature change will induce a 1nm color shift.

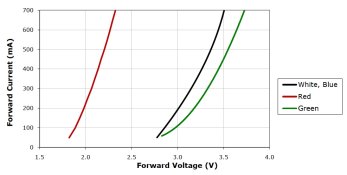

3: As junction temperature rises, forward voltage increases. This happens at a few mV per degree C/K. I have a feeling that this is not an issue as I drive the leds at constant current and not at voltage.

Here's what I observed: my nifty led thingy has a focus option that runs all leds at full power; after all, you want as much light as possible when focusing. When trying to track down the weird color inconsistencies I figured out that I got a color shift after having used the focus option for more than a few seconds (which is typical if you load a negative, position the easel and focus). If I exposed a print/strip within about 1-2 minutes after focusing, I get a print that is quit significantly shifted towards cyan. If I wait for about 2 minutes, the color of the print is consistent and repeatable.

My conclusion so far is that the red shift and/or the negative temperature/light output coefficient causes this issue. When using the focus option, the LEDs heat up by a few degrees (actually, the actual junction of the LEDs will heat up quite rapidly as thermal conductivity towards the heat sink is never perfect and power levels are fairly high at 3W/led), causing differences in color and light output. After a few minutes, temperature stabilizes again and color is back to 'neutral'.

This means that I have to figure out a way to stabilize the temperature of the leds better. I tried running the fans continuously, but aside from the fact that this is mildly annoying, it doesn't seem to help enough. Next thing I may try is to use a better thermal adhesive to bond the leds to the heat sink. I used a generic thermal glue but have ordered some Arctic Silver glue to see if it performs better. I may even go so far as to build a second (actually, third) light source module with more optimized thermal management.

In the meantime, I will just use a cool-down period between focusing and exposing a print or test strip. Some testing last night showed that this is adequate, but of course it's annoying to have 'dead time' in my workflow, so I want to get rid of that. Furthermore, this can only be a stopgap measure as the implication of the story above is that long exposure times (let's say more than a few seconds) will induce color shifts, which means that the same filtration settings at 3 seconds will not produce the same color on the paper as the same settings at, say, 30 seconds. And that can be annoying when e.g. burning/dodging (although I rarely do that with color).

So, in short: thermal management is an issue that requires careful management in designing a color LED head. I wonder how e.g. Heiland solved that issue (and if they actually have solved it). I do notice that on their light source they use a rather large, passive heat sink, which may work OK if thermal conductivity between the leds and the heat sink is near-perfect. But since it can never be truly perfect, I suspect their heads will have the same issue of color shifts as exposure times change considerably.

Last edited:

OK, a little follow-up on this. I ran into some weird consistency problems with color shifts between consecutive prints. Took me some time to figure out what was going on, but I think I got it. The problem is indeed related to thermal stability.

With LEDs, there are two things at play that spoil the broth, as it turns out:

1: As junction temperature rises, light output drops. This is a non-linear relationship and may likely (or perhaps definitely) be different for various types of junctions (i.e. it will be different for the different colors).

2: As junction temperature rises, the dominant wavelength (i.e. color) shifts towards longer wavelengths ('red-shift'). This happens at something like 0.1nm/K, so a 10 degree (C/K) temperature change will induce a 1nm color shift.

3: As junction temperature rises, forward voltage increases. This happens at a few mV per degree C/K. I have a feeling that this is not an issue as I drive the leds at constant current and not at voltage.

Here's what I observed: my nifty led thingy has a focus option that runs all leds at full power; after all, you want as much light as possible when focusing. When trying to track down the weird color inconsistencies I figured out that I got a color shift after having used the focus option for more than a few seconds (which is typical if you load a negative, position the easel and focus). If I exposed a print/strip within about 1-2 minutes after focusing, I get a print that is quit significantly shifted towards cyan. If I wait for about 2 minutes, the color of the print is consistent and repeatable.

My conclusion so far is that the red shift and/or the negative temperature/light output coefficient causes this issue. When using the focus option, the LEDs heat up by a few degrees (actually, the actual junction of the LEDs will heat up quite rapidly as thermal conductivity towards the heat sink is never perfect and power levels are fairly high at 3W/led), causing differences in color and light output. After a few minutes, temperature stabilizes again and color is back to 'neutral'.

This means that I have to figure out a way to stabilize the temperature of the leds better. I tried running the fans continuously, but aside from the fact that this is mildly annoying, it doesn't seem to help enough. Next thing I may try is to use a better thermal adhesive to bond the leds to the heat sink. I used a generic thermal glue but have ordered some Arctic Silver glue to see if it performs better. I may even go so far as to build a second (actually, third) light source module with more optimized thermal management.

In the meantime, I will just use a cool-down period between focusing and exposing a print or test strip. Some testing last night showed that this is adequate, but of course it's annoying to have 'dead time' in my workflow, so I want to get rid of that. Furthermore, this can only be a stopgap measure as the implication of the story above is that long exposure times (let's say more than a few seconds) will induce color shifts, which means that the same filtration settings at 3 seconds will not produce the same color on the paper as the same settings at, say, 30 seconds. And that can be annoying when e.g. burning/dodging (although I rarely do that with color).

So, in short: thermal management is an issue that requires careful management in designing a color LED head. I wonder how e.g. Heiland solved that issue (and if they actually have solved it). I do notice that on their light source they use a rather large, passive heat sink, which may work OK if thermal conductivity between the leds and the heat sink is near-perfect. But since it can never be truly perfect, I suspect their heads will have the same issue of color shifts as exposure times change considerably.

Laser cinema projectors also suffer from a not completely dissimilar heat problem - and their colour balance wanders if their temperature varies by more than a couple of degrees celcius - the solution is serious air conditioning - which is overkill for this situation, but the 138 was designed to be used with an offboard cooling fan quite readily - and a long enough hose would let you place the fan outside the darkroom.

@Lachlan Young yes, serious temperature control would be a solution, but it would require that the actual led dies are kept at constant temperature. This is very difficult, if not impossible, to achieve. A solution with fans (which I already have) is not adequate.

@Anon Ymous yes indeed, I have considered both options. An additional light source would be nice, but requires extensive modifications to the entire setup, so it's a major change. Therefore I'm planning to do a software update that runs the leds at 50% or even 25% output during focusing (at least in color mode as in b&w mode the problem is insignificant). It's a pity as it will make focusing more difficult, but it will give me a bit more time to focus without the leds heating up too much and I may find a light level at which temperature stabilizes at an acceptable level with minimal color shift in a following test strip or full print.

I think I'll also construct a new light source with a more massive heat sink and better thermal contact between the led chips and the heat sink, but that'll take a few weeks to get the components and assemble everything.

@Anon Ymous yes indeed, I have considered both options. An additional light source would be nice, but requires extensive modifications to the entire setup, so it's a major change. Therefore I'm planning to do a software update that runs the leds at 50% or even 25% output during focusing (at least in color mode as in b&w mode the problem is insignificant). It's a pity as it will make focusing more difficult, but it will give me a bit more time to focus without the leds heating up too much and I may find a light level at which temperature stabilizes at an acceptable level with minimal color shift in a following test strip or full print.

I think I'll also construct a new light source with a more massive heat sink and better thermal contact between the led chips and the heat sink, but that'll take a few weeks to get the components and assemble everything.

I think I'll also construct a new light source with a more massive heat sink and better thermal contact between the led chips and the heat sink, but that'll take a few weeks to get the components and assemble everything.

I have seen liquid cooled LED panels in the multi kW range, though it probably would involve custom machining!

Yeah, I briefly considered that too, but doing it right requires a range of manufacturing technologies I don't have easy access to. Machining a heat sink with fluid channels, soldering leds onto a copper or aluminium base PCB (and etching the PCB itself), bonding the PCB onto the heat sink...just a little too much for a DIY setting at home. Although the metal-base PCB option does sound appealing and I have thought about it before. But I did not find a quick & easy source for the raw material. I'm not too afraid of etching a PCB myself; I think I can get that down.I have seen liquid cooled LED panels in the multi kW range, though it probably would involve custom machining!

Yeah, I briefly considered that too, but doing it right requires a range of manufacturing technologies I don't have easy access to. Machining a heat sink with fluid channels, soldering leds onto a copper or aluminium base PCB (and etching the PCB itself), bonding the PCB onto the heat sink...just a little too much for a DIY setting at home. Although the metal-base PCB option does sound appealing and I have thought about it before. But I did not find a quick & easy source for the raw material. I'm not too afraid of etching a PCB myself; I think I can get that down.

You can also have the PCB milled rather than etched - which seems to be increasingly popular for one offs/ short runs & can be more precise than etching.

And regarding the peltier cooler, I suspect that the cost of the Heiland panel is probably because it uses something like that internally - a similar cooler was also used on the sensor in the faster Flextight scanners.

Last edited:

For one offs, toner transfer is also an option. The original method, where the print is ironed on the PCB is a bit tedious, but doable. I've seen a variation of it, which doesn't involve ironing, but a small amount of acetone. The artwork print is placed on the clean PCB and taped on it. Then few ml are dropped in the back of the paper, making sure that all of it is wetted, and light pressure is applied with a finger or so. This melts the toner slightly and makes it stick to the copper surface. The rest of the method is the same and a YouTube search will give you more descriptive videos. Any gaps where the toner didn't transfer well can be corrected with a permanent marker, like those used for writing on CDs.

- Joined

- Feb 17, 2008

- Messages

- 2,115

- Format

- Multi Format

However good your heatsink, there will always be the thermal resistance from junction to body. Maybe select high power LED model (actual criterion being low junction-case resistance), and operate at significantly less than rated power?

Another consideration. The temperature rise of the junction is not an issue per se if the settling time constant is significantly shorter than any operational time constant (exposure time, idle time between exposures). Presumably the time constant of the LED body (mounted on perfect heatsink) is much shorter than the time constant of a typical heatsink. This would nullify my comment above;

Another consideration. The temperature rise of the junction is not an issue per se if the settling time constant is significantly shorter than any operational time constant (exposure time, idle time between exposures). Presumably the time constant of the LED body (mounted on perfect heatsink) is much shorter than the time constant of a typical heatsink. This would nullify my comment above;

Last edited:

Yes, I have, but I think it's unnecessary - or rather: if Peltier cooling helps, then likely other means of cooling will also achieve the same. I think the main/critical issue is to get the heat away from the led die as rapidly as possible. I'm thinking along the same lines as @bernard_L here; it's junction temperature that is critical, and the question is how rapidly the junction stabilizes in terms of temperature under changing conditions. This is insanely difficult to test in a home setting, of course. The best I can do, I feel, is to make sure there is (1) as low as possible thermal resistance between the led and the cooling system and (2) overdimension the cooling system so that it does not heat up appreciably under normal operating conditions.@koraks Have you considered peltier cooling? It would be far simpler than any liquid cooling system, which would also probably introduce some vibrations. Regarding the PCB, the etching part is easy, transferring the artwork to the PCB is the complicated part IMHO.

And yes, for PCB manufacturing I'd look towards toner transfer initially as it's the most accessible method of DIY-ing PCB's. But again, the main bottle neck here is the lack of supply of usable and affordable metal-core PCB material. That would leave finding a party that is willing to do 1-offs at reasonable costs, which may be something I could look into at some point. But for now I think I'm just going to try gluing on leds to a piece of 3mm copper plate using Arctic Silver thermal adhesive and then glue the copper plate to a generously sized aluminum heat sink with a fan fitted onto it. If that doesn't help, likely nothing else will.

Yeah, provided reasonably good thermal contact between the led and the heat sink. That's where I have some doubts as I used very basic low-cost thermal glue. I don't think it makes for a very good thermal junction to be honest. It doesn't help that the thermally conducting surface of those leds is pretty darn small.However good your heatsink, there will always be the thermal resistance from junction to body. Maybe select high power LED model (actual criterion being low junction-case resistance), and operate at significantly less than rated power?

Another consideration. The temperature rise of the junction is not an issue per se if the settling time constant is significantly shorter than any operational time constant (exposure time, idle time between exposures). Presumably the time constant of the LED body (mounted on perfect heatsink) is much shorter than the time constant of a typical heatsink. This would nullify my comment above;

BTW, I've done some more testing and it seems like the problem may be manageable in practice. Turns out that for some arcane reason I don't understand yet, only the red channel suffers from this problem. This means that as long as I only use blue and green to focus/compose, I don't have a color shift in a subsequent exposure. I just tested this and updated the software in the controller and it seems to work like a charm. The only downside is obviously that I have less light available for focusing and it's cyan light instead of white, but it seems workable. I tested leaving the new cyan focus light on for 90 seconds and then immediately exposing prints at the desired filter settings and they came out without any visible color shifts.

I'm now left to wonder why it's only the red channel that's affected. There are a few hypotheses:

1: Same hypothesis as in post #30: color shift in the led due to heating up, which for some reason only affects the red leds (they're identical in construction to the blue and green ones, but obviously the junction type is different). However, there are a few things that go against this hypothesis. Firstly, the color shift (i.e. dominant wavelength shift) is likely to be in the vicinity of 0.1nm per degree. That's not a whole lot. A 40 degree temperature increase (which is a reasonable guess) would induce a 4nm shift. That wouldn't really explain the rather substantial color shift in the prints I'm getting. Secondly, if it is related to light output change in the leds due to their heating up, the effect is the exact opposite of what you'd expect - leds tend to get dimmer as they heat up, but these red ones seem to go in the opposite direction. Doesn't make sense.

2: Maybe it's not the leds, but the driver/current limiter. I use LM350T's to control current, and for blue and green, these run at less than 1A per piece. However, since I have twice as many red leds, and they're in series-parallel (two strands), this channel runs at something like 1.6A if memory serves. I made sure that the voltage overhead is minimal so that this channel doesn't overheat easily, but it will probably still run hotter than the other channels. Then again, all the LM350T's are mounted to the same heat sink, which doesn't get really warm when I run the lights at full power. So I'd be still stumped in this case.

3: A bit of a wild guess, but I use IRF740's to do the PWM switching. These are driven from essentially 5V logic, which is not very generous - but according to the datasheet, it should be more than enough for them to switch entirely off and on at this current level. But maybe I'm at the edge of what still works for the red channel that draws twice the current compared to the other channels? But again, it doesn't make perfect sense as you'd expect the mosfet to not switch on entirely on this channel, reducing the relative light output. Particularly since a mosfet has a positive Rds(on) temperature coefficient. So again, hotter = less light.

It all just doesn't compute. The only thing I know for now is that it works quite alright if I can live with cyan light focusing in color mode...

@koraks

Cyan light focus isn't a problem if you've used an Ilford MG500 head

Regarding the red drift from heat, what you describe as a couple of nm shift producing a bigger colour shift than expected, there's an interestingly similar problem with the latest generation laser light engines in digital cinema projectors, where if the grading viewing system and the projectors aren't held to within a couple of nm of their calibration aims, the colours will look quite badly off. It may be that you're essentially fighting the same problems from slightly different causes!

Cyan light focus isn't a problem if you've used an Ilford MG500 head

Regarding the red drift from heat, what you describe as a couple of nm shift producing a bigger colour shift than expected, there's an interestingly similar problem with the latest generation laser light engines in digital cinema projectors, where if the grading viewing system and the projectors aren't held to within a couple of nm of their calibration aims, the colours will look quite badly off. It may be that you're essentially fighting the same problems from slightly different causes!

Last edited:

Ah, so that's why it felt strangely familiar!Cyan light focus isn't a problem if you've used an Ilford MG500 head

That's very interesting about those projectors. Who knows it's the same thing indeed! I'm kind of hesitant at this point to blame the leds for this to be honest; the cyan shift in the prints just looks way too severe for only a few nm of red shift. It looks like something like 8cc of red added to the filter pack (or 8+8 y and m added to it if you will) on a regular color head - that's quite a lot. And there's a distinct increase in density as well, making me believe that there's actually more red being beamed out rather than a wavelength shift per se.

I looked up the lm350 dataset and its reference voltage has a positive temperature coefficient for sure, but again it seems too small at this temperature range (just a few degrees) to explain it. And there's the positive temperature coefficient of the pass resistor that would compensate for it, at least in part. So I'm still in the dark (red, haha) as to what's going on exactly.

Can you have the focusing LEDs pulse at a manageable rate rather than stay on continuously?

I did a quick test yesterday at a 50% duty cycle, and that improved the situation somewhat, but by far not acceptable. With blue+green at full power the problem doesn't manifest itself, and that is a workable compromise for me.

I ordered some parts for another light source; maybe the problem can be solved entirely. But I think I'll have to revise the driver circuitry as well.

I ordered some parts for another light source; maybe the problem can be solved entirely. But I think I'll have to revise the driver circuitry as well.

That's not a whole lot. A 40 degree temperature increase (which is a reasonable guess) would induce a 4nm shift. That wouldn't really explain the rather substantial color shift in the prints I'm getting.

I think it is a combination of multiple problems..

I had a quick look at a datasheet. For example, forward voltage of green and blue LEDs increases more with junction temperature than the voltage for red LEDs does.

Maybe your voltage for green and blue is too high for proper current regulation. You have to add voltage of LED plus voltage drop of your FET plus voltage drop of your shunt resistor at full current. If that total voltage exceeds your power supply voltage, the current drops.

Have you measured the current of all parts R, G and B in cold and hot situation?

On the other side, flux of red LED drops more with temperature as green and blue does. So this would be the opposite effect.

Another thing is the wavelength shift, you mentioned before. Depending what exactly wavelegth the LED has, effect will be different. Check out sensitivity curves of RA-4 paper. There is a kind of edge in the diagram for each R, G and B. If your working wavelength is at a flat part of the curve, the effect may be less. If the wavelength is at a steep part of the curve, the effect may be strong.

So you have to check out multiple things.

What exact types of LEDs are you using? Noname LEDs or specific brand?

Cheap noname LEDs without proper datasheet often create a big suprise in result.

Another question:

You use 2x the power for red.

The colour paper is somewhere 20x - 50x less sensitive for red as for blue and green.

A part of the filtration will be done via your red negative mask. But even when using masked negatives, your red part must be lots higher than the blue/green part.

You have to dim your green and blue LEDs during exposure using PWM or whatever. This will lower heat for G and B as well as current load.

Red is fired full power, so most heat will be created there.

Even if all LEDs are fired maximum load during focussing, G and B is much lower load during exposure. So G and B can cool down while R heats up more and more.

Just some of my thoughts..

I work with DIY Laser- and LED-imagers for RA-4 paper since many years. Partially for my hobby, partially for business.

And I stumbled over many many stones during the last years.

You can only achieve constant results, if ALL problems are solved, even if they seem small and unimportant.

When I saw the Intrepid 4x5 enlarger I was wondering if it would be easy to replace their LED board with colour LEDs to use it for RA4 printing. Perhaps it isn't that easy, after all.

With my LPL7700 enlarger I have the problem that the output is more than I'd like it to be. It is using a styrofoam diffusor box, the same for all negative sizes. I don't think that the effective output is all that high. Given the high sensitivity of RA4 paper couldn't you get away with lots of 'ordinary' LED without cooling, instead of those high powered ones?

Thanks for this, anyway, a very inspiring project!

With my LPL7700 enlarger I have the problem that the output is more than I'd like it to be. It is using a styrofoam diffusor box, the same for all negative sizes. I don't think that the effective output is all that high. Given the high sensitivity of RA4 paper couldn't you get away with lots of 'ordinary' LED without cooling, instead of those high powered ones?

Thanks for this, anyway, a very inspiring project!

@JoJo, you bring up a lot of relevant points. Indeed, many (all) of them have crossed my mind, but it's difficult to pinpoint a cause or even a likely combination of causes. Part of this has to do with the inadequate measurement equipment available to me; for example, there is no feasible way for me to accurately measure any shift in the dominant wavelength of LEDs. Please allow me to respond to a few of your comments:

As to constant results: fortunately I don't require lab-quality consistency, but it needs to be predictable enough to correct down to about 1cc in a single printing session (I can live with minor color shifts between summer and winter conditions for instance). I find I now achieve that when using only B and G for focusing. That's already quite surprising to me, if I'm honest. Let's see if I can push it further, although I have to admit that the pressure is gone somewhat now that essentially I can do what I set out to do.

Basically, I achieved my goal and now I have to decide how much further I want to push this at the cost of time I can also spend on making images...

I made sure to have a few volts overhead voltage for the current regulator and the driver FET. Current seems to be stable, but I'd have to recheck any cold/hot differences. I did study the datasheets of the FETs and current regulators and none of the data there give sufficient basis for a significant shift in light output. But that's theory.I think it is a combination of multiple problems..

I had a quick look at a datasheet. For example, forward voltage of green and blue LEDs increases more with junction temperature than the voltage for red LEDs does.

Maybe your voltage for green and blue is too high for proper current regulation. You have to add voltage of LED plus voltage drop of your FET plus voltage drop of your shunt resistor at full current. If that total voltage exceeds your power supply voltage, the current drops.

Have you measured the current of all parts R, G and B in cold and hot situation?

Exactly, so it doesn't work well as an explanation. It certainly happens (it's physics after all), but either the effect is insignificant, or other effects in the opposite direction are simply more significant.On the other side, flux of red LED drops more with temperature as green and blue does. So this would be the opposite effect.

I have checked these and yes, the red leds are still in the steep part of the red response curve. Meaning that a small shift would induce a bigger shift in response. However, given the expected shift (~4nm over a 40C temperature change), the cyan shift in the prints still seems inexplicably high. Furthermore, a similar shift would be expected in the B and G channels, albeit possibly of different magnitude. I observe no such effect, which would raise the question why the red leds would respond so dramatically to a temperature shift while B and G don't. These are of course different materials/junction types, but shifts tend to be in the same order of magnitude.Another thing is the wavelength shift, you mentioned before. Depending what exactly wavelegth the LED has, effect will be different. Check out sensitivity curves of RA-4 paper. There is a kind of edge in the diagram for each R, G and B. If your working wavelength is at a flat part of the curve, the effect may be less. If the wavelength is at a steep part of the curve, the effect may be strong.

So you have to check out multiple things.

This could very well be the issue. I searched a bit and in the end, non-name, no-datasheet, unknown-manufacturer leds turned out to be the only feasible option for initial testing, so that's what I use. Unfortunately, that leaves many unknowns as you point out. In a perfect world, I would have used well-documented, narrow- and controlled bandwidth leds from a reputable manufacturer - but my pockets have only limited depth.What exact types of LEDs are you using? Noname LEDs or specific brand?

Cheap noname LEDs without proper datasheet often create a big suprise in result.

Absolutely. However, if it's a temperature related issue in the LEDs themselves, this would still be odd. I experimentally observed that the necessary cool-down period is about 2 minutes. Exposure times during testing were typically 3-4 seconds. Additional cooling at a faster rate within the B and G leds during the 3-4 second exposure would therefore fall away into the background. Based on my experiments, I don't think the issue is related to how hard the leds are driven in relation to each other - there's just something different to the R channel compared to B and G. As you mentioned, the R channel is roughly twice the power of the B and G channels so that's why I'm leaning somewhat towards the difference in driving circuitry, specifically the current limiters, for explaining the shift. Haven't gotten round to cobbling up some new drivers though; hopefully I'll find the time for that soon.Another question:

You use 2x the power for red.

The colour paper is somewhere 20x - 50x less sensitive for red as for blue and green.

A part of the filtration will be done via your red negative mask. But even when using masked negatives, your red part must be lots higher than the blue/green part.

You have to dim your green and blue LEDs during exposure using PWM or whatever. This will lower heat for G and B as well as current load.

Red is fired full power, so most heat will be created there.

Even if all LEDs are fired maximum load during focussing, G and B is much lower load during exposure. So G and B can cool down while R heats up more and more.

Just some of my thoughts..

Your experience is much appreciated and I'm all ears as to the hurdles you've met and solutions you've found! Please share them if you want!I work with DIY Laser- and LED-imagers for RA-4 paper since many years. Partially for my hobby, partially for business.

And I stumbled over many many stones during the last years.

You can only achieve constant results, if ALL problems are solved, even if they seem small and unimportant.

As to constant results: fortunately I don't require lab-quality consistency, but it needs to be predictable enough to correct down to about 1cc in a single printing session (I can live with minor color shifts between summer and winter conditions for instance). I find I now achieve that when using only B and G for focusing. That's already quite surprising to me, if I'm honest. Let's see if I can push it further, although I have to admit that the pressure is gone somewhat now that essentially I can do what I set out to do.

Basically, I achieved my goal and now I have to decide how much further I want to push this at the cost of time I can also spend on making images...

Many thanks!When I saw the Intrepid 4x5 enlarger I was wondering if it would be easy to replace their LED board with colour LEDs to use it for RA4 printing. Perhaps it isn't that easy, after all.

With my LPL7700 enlarger I have the problem that the output is more than I'd like it to be. It is using a styrofoam diffusor box, the same for all negative sizes. I don't think that the effective output is all that high. Given the high sensitivity of RA4 paper couldn't you get away with lots of 'ordinary' LED without cooling, instead of those high powered ones?

Thanks for this, anyway, a very inspiring project!

Yes, you could use a lot of small low-power leds instead of fewer high-power leds. It might make it a bit more difficult to make an effective diffuser; currently, my light source is of a similar area as the maximum negative size, which in practice works quite conveniently (and fits inside the 138s head). Lower-powered leds would either result in a larger surface area of the light source or lower total light output. I wouldn't myself want to compromise on the latter; in fact, the next light source I will construct will likely increase the number of green leds (so a ratio of 2:2:1 for R:G:B whereas I now have 2:1:1) to make b&w printing faster. The problem with lower power is that exposure times escalate; it's a powers-of-two relationship after all. Especially with smaller formats (e.g. 35mm) this can become problematic at some point.

If you were to cram a lot of small leds together on as small as possible surface area, there may be some advantage in terms of heating up of the led dies themselves, but you'd still have to get rid of the large overall amount of power, of course. But maybe that's easier than keeping the dies cool, since those are buried within the manufacturer's led component and therefore possibilities of cooling the dies directly are very limited.

Many thanks!

Yes, you could use a lot of small low-power leds instead of fewer high-power leds. It might make it a bit more difficult to make an effective diffuser; currently, my light source is of a similar area as the maximum negative size, which in practice works quite conveniently (and fits inside the 138s head). Lower-powered leds would either result in a larger surface area of the light source or lower total light output. I wouldn't myself want to compromise on the latter; in fact, the next light source I will construct will likely increase the number of green leds (so a ratio of 2:2:1 for R:G:B whereas I now have 2:1:1) to make b&w printing faster. The problem with lower power is that exposure times escalate; it's a powers-of-two relationship after all. Especially with smaller formats (e.g. 35mm) this can become problematic at some point.

If you were to cram a lot of small leds together on as small as possible surface area, there may be some advantage in terms of heating up of the led dies themselves, but you'd still have to get rid of the large overall amount of power, of course. But maybe that's easier than keeping the dies cool, since those are buried within the manufacturer's led component and therefore possibilities of cooling the dies directly are very limited.

The intrepid people build their lightsource for 4x5 only and I guess they are using white LED. On the images it looks like it is just over 4x5 in size itself.

So my idea was simpler than your requirements, in case it would make a difference: 4x5 colour only. I was contemplating SMD LEDs.

Order the PCB from beta-Layout with a solder mask. We have their simple solder paste printer at work and a tabletop oven (yes, made for the kitchen) with their solder profile controller. I used it a few years ago for a prototype and it worked beautifully. Again my hope was that lots of SMD LED on a 4x5 PCB would be bright enough for RA4. I'd love some more time than the 8s on my LPL for consistency, for making smaller prints than 24x30 cm2 and possibly doge&burn, even though I hate that. Of course then I'd need one in 6x7 for my current enlarger...

For 4x5 b/w one can use the Intrepid light source with multigrade filters, or rebuild it with LEDs specifically for multigrade printing. But I hardly find enough time to drive to my dark room, let alone start this electronics project. Especially as it doesn't look so straight forward anymore.

- Joined

- Jul 14, 2011

- Messages

- 14,780

- Format

- 8x10 Format

I'd be wary of lack of brightness as well as deficient color accuracy compared to traditional halogen colorheads. But experimentation with LED heads is evidently the future. I don't trust Beseler to get it right either, given their track record of overtly-complicated heads they refuse to service when the problems get overwhelming. It can be done; it just takes a degree in Psychiatry plus another degree in Electrical Engineering, so you can specialize in schizophrenic circuits. Been there, done that.

| Photrio.com contains affiliate links to products. We may receive a commission for purchases made through these links. To read our full affiliate disclosure statement please click Here. |

PHOTRIO PARTNERS EQUALLY FUNDING OUR COMMUNITY:  |