Thank you!That's a great idea! Building a large-format leaf shutter is a challenging but rewarding project.

-

Welcome to Photrio!Registration is fast and free. Join today to unlock search, see fewer ads, and access all forum features.Click here to sign up

- Home

- Forums

- Analog Workflow Forums (100% Analog/Traditional)

- Analog Equipment

- Camera Building, Repairs & Modification

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building a huge shutter for large format lenses

-

A

- Thread starter kuvaharrastaja

- Start date

Recent Classifieds

-

For Sale FS: Nicola Perscheid 36cm f/4.5 Lens

- Started by B.S.Kumar

-

For Sale Kodak Commercial EKTAR 8 1/2 f6.3 in Ilex 3 shutter

- Started by Simon Benton

-

For Sale Canon RF 600mm f11, RF 100-400 Lenses

- Started by Jon Shiu

-

For Sale Fujifilm MAXIMA Glossy RA-4 Paper; Packs of 16x20 Sheets

- Started by Aidan Sciortino

-

Sold 1924 Carl Zeiss Jena 150mm f4.5 Lens in dial Compur

- Started by Jon Shiu

Forum statistics

Thats interesting! I found (probably) your post and picture of that shutter/lens assembly. Thanks for sharing it.Hmm. OP, are you aware of the AGI F.135 aerial camera? It uses 5" roll film, has two very strange leaf shutters that hold 38/4.5 Biogons. Not a stereo camera, the shutters fire alternately, the film is advanced after two shots. The shutters embody a few ideas that you might want to consider.

The shutters' blades are metallized mylar, are probably lighter than the equivalent steel blades. Less inertia.

The shutter is opened/closed by a pair of opposed solenoids that extend when energized. The open solenoid whacks a lever that opens the blades, the close shutter whacks the lever to close them.

I wonder why its done using two solenoids? I know that normal solenoid just pulls even if put to reversed polarity. Shop's sell push/pull solenoids, Maybe those have magnet inside a coil, like a speaker. I dont have one to explore.

But this is probably best way to go. Either 2 solenoids pulling oppositely. Or single push/pull solenoid, if those are any good.

I already have hard spring steel shutter blade material, it should be good to drive as is. No need to rivet thicker piece to it for "bearing material" ,at least I hope it handles those hits from driving pin.

Thats cool idea! It would be able to have good maybe felt material light seals too, if the motor pulls the slide and not just gravity and tilting the camera possible.One thing you might consider is a guillotine type shutter, but using your electric driver (stepper motor with ,lead screw or solenoid) instead of the gravity fall common in homebuilt guillotine shutters.

This doesn't absolutely require a very fast travel; like a focal plane shutter, exposure time is mainly governed by the width of the slit -- but if you drive with a stepper, you could have a fixed width slit and vary the drive speed instead.

This probably woudnt work or anything moving, or portraits though? Hard to simulate in head, how it would go, but I get the feeling something weird could happen.

One thing also why i didnt go with quillotine type shutter is the size/limiting experience. The slide would have to fit big 14cm area first to block light, then the slit, and then again area to block light. And the slide with flash sync (on regular guillotine shutter), would probably have to have 14cm hole in the middle as well. So worst case scenario the shutter would have to be at about 18cm wide, and lenght of it almost 50cm. Also it would probably hit monorail, if that kind of camera is in use.

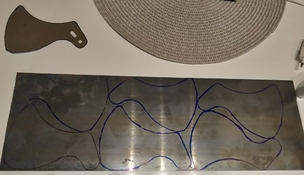

Here's a little picture series making of shutter leafs/blades.

From shanel shutter picture, Ive scaled up and printed, to get paper model for the right shape and size. The size is modified for the leafs radius to match 140mm.

Ordered 0.2mm spring steel sheet some time ago. Luckily this size shutter leaf (6pcs) just fit on there.

Leafs were cut out with angel grinder, because it doesnt warp or twist material, like tin snips.

After this leafs were hot glued together, in oven at 180c, and squeezed together between plywood pieces. This helps me to get 6 similar pieces at once using belt sander and die grinder with stone.

I have to still make the round 5mm hole and slot similarly how they are in paper model, glued to leaf stack. The sheets are really hard and were very slippery with angel grinder, and file bites only very little, like in knife.

Have to do some tests how the cutting those features will go, Maybe with some carbide endmill on a my little milling machine.

From shanel shutter picture, Ive scaled up and printed, to get paper model for the right shape and size. The size is modified for the leafs radius to match 140mm.

Ordered 0.2mm spring steel sheet some time ago. Luckily this size shutter leaf (6pcs) just fit on there.

Leafs were cut out with angel grinder, because it doesnt warp or twist material, like tin snips.

After this leafs were hot glued together, in oven at 180c, and squeezed together between plywood pieces. This helps me to get 6 similar pieces at once using belt sander and die grinder with stone.

I have to still make the round 5mm hole and slot similarly how they are in paper model, glued to leaf stack. The sheets are really hard and were very slippery with angel grinder, and file bites only very little, like in knife.

Have to do some tests how the cutting those features will go, Maybe with some carbide endmill on a my little milling machine.

Attachments

jonathanchli

Member

You mean that square body sinar db shutter? Ive googled some pics from insides of that, but coudnt find pics of the mechanism how is the shutter leafs moved in that.

But ive already kinda gone with this 5 leaf desing that seems to be most popular in shutters.

Perhaps you may find this video useful

My question is what format?

There are various options, first as mentioned already the Sonar/Copal shutter, I bought one in January at a camera fair for £20. O assume the seller thought it needed repair as it did not work with a cable release, It just needed the special extra long throw dedicated cable release and works fine.

I'm lucky I have large Thornton Pickard roller blind shutters that fit all my large barrel lenses, and also a large Gitzo leaf shutter with flash sync, these are front mounted.

Another option is a focal plane shutter, I have two half plate shutters that can be rear fitted, also a dual shuttered TP Triple Imperial, focal plane shutter for high speeds to 1/1000, and behind lens roller blind shutter for slower speeds.

Some years ago I bought a box of Graflex parts from Paris, off a member here. He had stripped down Quarter plate Speed graphics to use the focal plane shutters between large lenses and his camera's lens board.

Ian

There are various options, first as mentioned already the Sonar/Copal shutter, I bought one in January at a camera fair for £20. O assume the seller thought it needed repair as it did not work with a cable release, It just needed the special extra long throw dedicated cable release and works fine.

I'm lucky I have large Thornton Pickard roller blind shutters that fit all my large barrel lenses, and also a large Gitzo leaf shutter with flash sync, these are front mounted.

Another option is a focal plane shutter, I have two half plate shutters that can be rear fitted, also a dual shuttered TP Triple Imperial, focal plane shutter for high speeds to 1/1000, and behind lens roller blind shutter for slower speeds.

Some years ago I bought a box of Graflex parts from Paris, off a member here. He had stripped down Quarter plate Speed graphics to use the focal plane shutters between large lenses and his camera's lens board.

Ian

This probably woudnt work or anything moving, or portraits though? Hard to simulate in head, how it would go, but I get the feeling something weird could happen.

The transit time of the shutter slit establishes the motion limit, but that's 1/4 second or so for the old Speed Graphic focal plane shutters (at least my Anniversary); it shouldn't be impossible to get a stepper with suitable lead screw to move the guillotine panel(s) across the working area in less time than that. You'll need a stepper driver, of course, to let you select drive speeds, or a means of setting the slit width (or both).

Also, most guillotine shutters are mounted in front of the lens, so fitting the mechanism inside the bellows isn't an issue. Plus, it makes it easy to move the shutter between lenses. You could use standoffs on the lens board to position and steady the shutter.

Just to trow it out there, have you considered a rotary shutter? Seems simpler to build than a leaf shutter and can probably achieve higher travel speeds than a linear travel curtain shutter, because it can accelerate before reaching the aperture (which is also possible with a linear shutter, but would make it quite unwieldy).

- Joined

- Mar 23, 2005

- Messages

- 6,934

- Format

- Multi Format

I wonder why its done using two solenoids? I know that normal solenoid just pulls even if put to reversed polarity. Shop's sell push/pull solenoids, Maybe those have magnet inside a coil, like a speaker. I dont have one to explore.

Two opposed shutters. One pushes to open, then retracts. The other pushes to close, then retracts. The shutter end of the actuating lever moves farther and faster than the solenoid end. I've had nine F.135 cameras, never had the power supply or control electronics. I bought them for their 38/4.5 Biogons, which paid for many other acquisitions.

The reason for an open and a close solenoid is simple - without a close solenoid the shutter has to be closed using a spring. The solenoid, of course, has to overcome the spring to open the shutter. The spring tension has to be such that its force is enough to close the shutter in the required time. For small shutters this isn't much of a problem, for large ones it is.

without a close solenoid the shutter has to be closed using a spring

Many generic solenoids have a spring-mounted plunger. This type is likely adequate for this shutter project.

I have diy 5x7 camera that is built so that it can fit almost everything, so that will be used.My question is what format?

There are various options, first as mentioned already the Sonar/Copal shutter, I bought one in January at a camera fair for £20. O assume the seller thought it needed repair as it did not work with a cable release, It just needed the special extra long throw dedicated cable release and works fine.

I'm lucky I have large Thornton Pickard roller blind shutters that fit all my large barrel lenses, and also a large Gitzo leaf shutter with flash sync, these are front mounted.

Another option is a focal plane shutter, I have two half plate shutters that can be rear fitted, also a dual shuttered TP Triple Imperial, focal plane shutter for high speeds to 1/1000, and behind lens roller blind shutter for slower speeds.

Some years ago I bought a box of Graflex parts from Paris, off a member here. He had stripped down Quarter plate Speed graphics to use the focal plane shutters between large lenses and his camera's lens board.

Ian

For that the shutter might sound overkill, but its for the lenses, not the camera. And will be good for ultra large format camera too, if I decide to build one someday.

I am sure those options are nice to have! That sinar shutter was a find for 20 lol.

Mamiya rb/rz and tlr cameras, almost all large format shutters, copal, compound, shanel etc.. are using similar design that I am building. And those are very reliable.

I am sure it might work too, with the rotary disk thing built ultra light so that it wouldnt knock tripod over when accerelating/slowind down.Just to trow it out there, have you considered a rotary shutter? Seems simpler to build than a leaf shutter and can probably achieve higher travel speeds than a linear travel curtain shutter, because it can accelerate before reaching the aperture (which is also possible with a linear shutter, but would make it quite unwieldy).

Yeah, theres no hope pulling the shutter back closed with a spring, or it would reguire huge solenoid and spring.The reason for an open and a close solenoid is simple - without a close solenoid the shutter has to be closed using a spring. The solenoid, of course, has to overcome the spring to open the shutter. The spring tension has to be such that its force is enough to close the shutter in the required time. For small shutters this isn't much of a problem, for large ones it is.

What I meant was, aren't there solenoids that can pull and push, with reversing the polarity. Tried to google but only push/pull solenoids I found, were indeed regular pull solenoids equipped with small spring. lol.

In speakers there is electromagnet coil inside of a magnet, and it can pull and push just as hard, i think.

Yes, for sure! But with bigger size and 2 of them. The shutter needs to be built first and then its easier to see what kind of force it needs to move.Many generic solenoids have a spring-mounted plunger. This type is likely adequate for this shutter project.

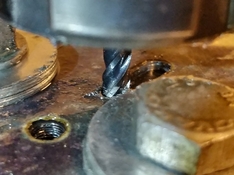

View attachment 378552

Shutter leafs are coming out pretty good, managed to machine the 5mm wide hole and groove pretty accurately. Still need to remove hot glue residue and take burrs off from edges.

I have drill press converted to a little milling machine It was a bit challenging job, because that material, 0.2mm spring steel sheet. Its hard and has a lot of give. Glueing them together helped great deal.

It was a bit challenging job, because that material, 0.2mm spring steel sheet. Its hard and has a lot of give. Glueing them together helped great deal.

Been thinking about making the ring that turns leafs, from a car's coil spring. Maybe that kind of hard steel would be good gliding properties with cast aluminium shutter body. With also being able to be light and rigid enough.

The ring needs to be narrow, maybe 19cm od and 17cm id. Or something like that. Not sure about thickness.

I have drill press converted to a little milling machine

It was a bit challenging job, because that material, 0.2mm spring steel sheet. Its hard and has a lot of give. Glueing them together helped great deal.

It was a bit challenging job, because that material, 0.2mm spring steel sheet. Its hard and has a lot of give. Glueing them together helped great deal.Been thinking about making the ring that turns leafs, from a car's coil spring. Maybe that kind of hard steel would be good gliding properties with cast aluminium shutter body. With also being able to be light and rigid enough.

The ring needs to be narrow, maybe 19cm od and 17cm id. Or something like that. Not sure about thickness.

Attachments

So far it looks nice. I'm guessing the shutter will be slow due to the length of the blades. Rotational inertia proportional to radius squared!

Problem with 20 or so lightweight blades woud be friction. I'm curious to see how it turns out. Nothing wrong with a slow shutter for Large Format photography.

Problem with 20 or so lightweight blades woud be friction. I'm curious to see how it turns out. Nothing wrong with a slow shutter for Large Format photography.

Thank you! Hmm, I have a goal to make the shutter go about 1/30s or shorter. The 5 leaf design should allow relatively small/light invidual blade size and mass.So far it looks nice. I'm guessing the shutter will be slow due to the length of the blades. Rotational inertia proportional to radius squared!

Problem with 20 or so lightweight blades woud be friction. I'm curious to see how it turns out. Nothing wrong with a slow shutter for Large Format photography.

Also hardened steel drive pins will be used, so its not going to break with bigger solenoids, there can be makita tool battery with big current available, hundreds of watts.

Thats the plan anyway

Found this car spring from trash, here its used to make a billet/blank for the ring that turns the leafs!

It weights 610g now, and on a lathe it takes shining slippery surface when cut! Unlike furniture grade steel.

All the welding is done with big current, penetrating troughout the material, so the piece should be consistent at the joints too.

It weights 610g now, and on a lathe it takes shining slippery surface when cut! Unlike furniture grade steel.

All the welding is done with big current, penetrating troughout the material, so the piece should be consistent at the joints too.

Attachments

It's not the pins that will break. Shutters that move quickly have small brass rivets crimped into the shutter blades, else the pins will wear out the holes in the blades and at the same time the blades will cut grooves in the pins.

Brass is usually used with aluminum, along with a lubricant, when making a sliding surface. I have never seen a steel/aluminum bearing surface, my guess is that galling will be a problem. The best interface is hardened steel and sintered bronze; the bronze will be oil impregnated.

If you are looking for push-pull solenoids you will need to look into linear motors, sometimes called 'voice coil motors.' If you want to use them without a restoring spring you will need a feedback system for positioning. The moving part of the motor is a magnet, in a speaker the moving part is the coil, or you can have a moving coil and a field coil - all just like DC motors.

Solenoids are unstable - the force increases very quickly as the solenoid closes. The force/distance relationship isn't linear like it is with a spring. There are special solenoids made for positioning but they are really voice coil style motors that only generate force in one direction; the construction is different in that the force is proportional to current and position.

Brass is usually used with aluminum, along with a lubricant, when making a sliding surface. I have never seen a steel/aluminum bearing surface, my guess is that galling will be a problem. The best interface is hardened steel and sintered bronze; the bronze will be oil impregnated.

If you are looking for push-pull solenoids you will need to look into linear motors, sometimes called 'voice coil motors.' If you want to use them without a restoring spring you will need a feedback system for positioning. The moving part of the motor is a magnet, in a speaker the moving part is the coil, or you can have a moving coil and a field coil - all just like DC motors.

Solenoids are unstable - the force increases very quickly as the solenoid closes. The force/distance relationship isn't linear like it is with a spring. There are special solenoids made for positioning but they are really voice coil style motors that only generate force in one direction; the construction is different in that the force is proportional to current and position.

Last edited:

That pin thing is very true, I thought a lot about a design where every leaf had a 3mm thick piece of hard aluminium plate riveted around pin areas, to prevent pins eating into leafs.It's not the pins that will break. Shutters that move quickly have small brass rivets crimped into the shutter blades, else the pins will wear out the holes in the blades and at the same time the blades will cut grooves in the pins.

Brass is usually used with aluminum, along with a lubricant, when making a sliding surface. I have never seen a steel/aluminum bearing surface, my guess is that galling will be a problem. The best interface is hardened steel and sintered bronze; the bronze will be oil impregnated.

If you are looking for push-pull solenoids you will need to look into linear motors, sometimes called 'voice coil motors.' If you want to use them without a restoring spring you will need a feedback system for positioning. The moving part of the motor is a magnet, in a speaker the moving part is the coil, or you can have a moving coil and a field coil - all just like DC motors.

Solenoids are unstable - the force increases very quickly as the solenoid closes. The force/distance relationship isn't linear like it is with a spring. There are special solenoids made for positioning but they are really voice coil style motors that only generate force in one direction; the construction is different in that the force is proportional to current and position.

I decided to go with similar design than in original shutter, just holes in the leafs. But I have 5mm pins instead of 2mm, and thickness of leaf is doubled 0.1mm to 0.2mm. To compensate increased load.

Pin material is some sort of axle steel, that has some sort of hardening and ground finish.

This might be a weak link, but might also be that shutter will last just fine on my usage. If the pins eat into leafs already in testing phase, its easy enough to machine room for rivets and make new leafs with bearing material riveted.

Steel and aluminium bearing surfaces are used in car engines a lot.

Thats a lot of good info. Thank you! I have to check out those solenoids. Already have couple of car starter motor solenoids, but those are pretty heavy.

The shutters ring have solenoid mounting points on opposite sides. Maybe pulling from each side to opposite directions will reduce ring friction and cancel out some shaking.

Yes and no. The famous example is an aluminum engine block and steel piston rings as in the General Motors Chevrolet Vega. General Motors tried several times to be cheap/sophisticated by depositing a layer of nikasil (nickel/silicon carbide) on the cylinder bores. In combination with engine overheating (GM also decided big radiators were too expensive) the nikasil coating failed and the piston rings promptly ate into the cylinder walls. The proper solution is to have iron sleeves in the cylinders - then all is good, and if the cylinders do get scored then replacing the sleeves is a lot easier than re-boring the block.Steel and aluminium bearing surfaces are used in car engines a lot.

GM had the same problem with its early 60's aluminum V8 - they sold the design to Rover in the UK who promptly sleeved the engine and all was good.

Steel in aluminum heads is always riding on bearing material. The bearing material is always stationary WRT aluminum.

Sure the aluminium will wear with piston rings, but for example chevy 305 engine that has piston pins pressed solid on the con rod. The bore on aluminium piston is the bearing there.

Also with almost all engines that have over head cams, the cams running straight on the aluminium bores. No bearing slips used.

Sure the cams are some kind of cast steel, but people use aftermarket forged steel cams too. I dont think that the cast steel cam is not what makes it possible, but the design and oiling etc.

Also with almost all engines that have over head cams, the cams running straight on the aluminium bores. No bearing slips used.

Sure the cams are some kind of cast steel, but people use aftermarket forged steel cams too. I dont think that the cast steel cam is not what makes it possible, but the design and oiling etc.

if the cylinders do get scored then replacing the sleeves is a lot easier than re-boring the block

I know this is something my dad did (had done) on his Citroën DS back around 1970 or so. That's the most recent occurrence I've heard of cylinder re-sleeving in my social circle.

Richard Man

Subscriber

- Joined

- Sep 24, 2005

- Messages

- 1,325

- Format

- Multi Format

This is looking awesome. Good luck!

| Photrio.com contains affiliate links to products. We may receive a commission for purchases made through these links. To read our full affiliate disclosure statement please click Here. |

PHOTRIO PARTNERS EQUALLY FUNDING OUR COMMUNITY:  |