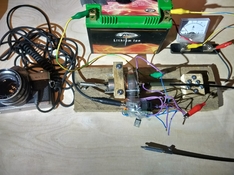

It's an amazing task. It's probably way too late to make any meaningful suggestions, but I'd probably personally opt for a solution involving a completely separate shutter for those open shots, and a more standard shutter for other use. That's purely from looking at things in a modular way. It would reduce wear to when it is necessary. Also (in the sense of the hammer-owner to whom every problem is a nail), and because I have one handy, I'd probably opt for compressed air (I mean a serious compressor) if I wanted that type of torque, both in opening and closing. Slower than a solenoid, but do you need instant response, or do you need that short exposure more? You won't be taking sport shots obviously!

It's a fascinating problem. Good luck with it!

It's a fascinating problem. Good luck with it!

That guy looks determined to use the gas! It would actually be nice idea to use co2 tank for example, if going to that pneumatic way.

That guy looks determined to use the gas! It would actually be nice idea to use co2 tank for example, if going to that pneumatic way.