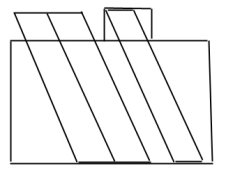

Well I made some progress of the holiday. The weather was crummy and so I started in on the box. Joe, I was wrong about coffers circum. The 90" was the length and he made ~140" circum. That still sounds a bit much to me. I got some $1/yd fabric and made a quickie shroud. It was 60" wide fabric like the stuff from porter's (which is 60" but without fringe is 58"). I sewed it so there was ~120" circum. I then tacked it in the box to see how it would fit. I believe coffer said to stretch tight the bottom and sides and pleat at the top. Well after messing with it for a bit, I realized it's best (with my design) to have the top and bottom tight and pleat the sides. The reason being is the sides 'grow' after the come out of the box up to the top of the holder over the head. Thus, they need extra fabric to do that. I redid the temp shroud like that and it worked much better.

I will be installing the 'real' shroud tonight, because I went ahead and threw some stain and poly on the box first.

Joe, I went with your "three pole on the top door" design to hold up the shroud. The final part of that will be incorporated tonight as well.

It will basically be ready for car or table top use after that.

I have been mulling over what to do about legs. Joe, I really like your incorporated style and the wheels. Yesterday, I had a brainstorm that I think I'm going to try. I have this little table at home that folds up for storage. One set of legs detaches and goes to the other set so they are pressed together. I 'think' I could make a table/dolly combo thingie gizmo

so I could convert a table (to put the box on) into a dolly (to haul the box around). I just need to hit the hardware store and look at hardware options. At any rate, I'm excited to get out in the field!

so I could convert a table (to put the box on) into a dolly (to haul the box around). I just need to hit the hardware store and look at hardware options. At any rate, I'm excited to get out in the field!

so I could convert a table (to put the box on) into a dolly (to haul the box around). I just need to hit the hardware store and look at hardware options. At any rate, I'm excited to get out in the field!