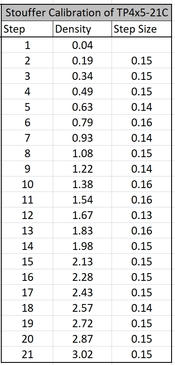

I'm disappointed with this calibrated step wedge I received in the mail today from Stouffer. I scanned the wedge as a document to show the black spots at steps #1, #2, #3, and #6, there could be more. You can see where I wrote in pencil the density increments between the steps on the step density chart. A differentiation of .14 density and .15 density is not that concerning, but the second half of the wedge density increments are bothersome to me. Am I being too critical of this step wedge?

-

Welcome to Photrio!Registration is fast and free. Join today to unlock search, see fewer ads, and access all forum features.Click here to sign up

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Stouffer step wedge I received today (January 23, 2023).

-

A

- Thread starter Chuck_P

- Start date

Recent Classifieds

-

For Sale Kodak 2465 microfilm

- Started by MCB18

-

Want to Buy Linhof Technika 4x5 240 cam.

- Started by Logical1

-

Free Free Darkroom Stuff

- Started by Reinhold

-

For Sale Zeiss Distagon 35mm f2 ZF Industrial

- Started by Jammoh

-

For Sale FS: Fujinon 250mm f/6.7 Lens

- Started by B.S.Kumar

Forum statistics

Yeah, I think I'd be sending that back...

"Calibrated" just means they read the densities for you from a calibrated source. Not that the wedge values are "calibrated" be be exactly 1/2 stop apart.

Did they say why they gave two densities for step 11?

Ok, but is it expecting too much....to expect......the density increments to be more like the first half of the step wedge?

I just got it today, so I will give them a call tomorrow and ask them about step 11 and the eratic nature of steps 11 - 21

- Joined

- Feb 9, 2010

- Messages

- 9,463

- Format

- 4x5 Format

This is absolutely normal. The nominal values are not easy to manufacture across the scale, especially in the higher densities.

Calibrated means they read it. You would hope they picked a “good” specimen to begin with but a little variation like this is expected.

When you graph the values, you use those actual readings as the marks on the exposure axis. Many spreadsheet programs have a place for these actual values.

There’s two readings of step 11 because it’s repeated, on both left and right side at the bottom.

Calibrated means they read it. You would hope they picked a “good” specimen to begin with but a little variation like this is expected.

When you graph the values, you use those actual readings as the marks on the exposure axis. Many spreadsheet programs have a place for these actual values.

There’s two readings of step 11 because it’s repeated, on both left and right side at the bottom.

tom williams

Subscriber

I'd send it back. The staining would be sufficient cause, but I would be unhappy with the deviations from 0.15 in the step density differences of your wedge. I've attached a copy of similar measurements I made of the Stouffer 4x5 step wedge I'm using now. I don't remember the tolerances that Stouffer advertises, but I very dimly recall +-0.02. Mind you, this is a sample aize of 1.I'm disappointed with this calibrated step wedge I received in the mail today from Stouffer. I scanned the wedge as a document to show the black spots at steps #1, #2, #3, and #6, there could be more. You can see where I wrote in pencil the density increments between the steps on the step density chart. A differentiation of .14 density and .15 density is not that concerning, but the second half of the wedge density increments are bothersome to me. Am I being too critical of this step wedge?

Just the printed in dirt would make me reject it.

That's just sloppy.

That's just sloppy.

Just the printed in dirt would make me reject it.

That's just sloppy.

Yes, I'm feeling the same way at the moment.

I'd send it back. The staining would be sufficient cause, but I would be unhappy with the deviations from 0.15 in the step density differences of your wedge. I've attached a copy of similar measurements I made of the Stouffer 4x5 step wedge I'm using now. I don't remember the tolerances that Stouffer advertises, but I very dimly recall +-0.02. Mind you, this is a sample aize of 1.

View attachment 327483

I feel I would have nothing to complain about if my tablet looked like that.

tom williams

Subscriber

But if you're reluctant to return the tablet, I think I would trust Bill Burke's suggestion. It makes sense to me that plotting the measured densities on your test negative against the measured densities on the step tablet would give a valid result. It's just that the intervals between data points aren't all equal, as they would be if your step tablet had exactly 0.15 change in density from one step to the next.I feel I would have nothing to complain about if my tablet looked like that.

Now that I've thought about that, I realize that I might be able to resurrect an old step tablet that I discarded when it became slightly mottled.

I believe the uneven increments have two causes: (1) Uneven development, and (2) unevenness in their sensitometer that exposed this film. As others have said, such unevenness is normal. The spots are not.

Mark

Mark

- Joined

- Feb 9, 2010

- Messages

- 9,463

- Format

- 4x5 Format

They may not be able to give you a cleaner copy of this step wedge. The specks may be on their master neg.

But they may be able to provide one that comes closer to specifications.

Literally, I think step 12 is outside of specifications because it’s more than 0.02 from nominal.

But it’s perfectly usable as-is.

But they may be able to provide one that comes closer to specifications.

Literally, I think step 12 is outside of specifications because it’s more than 0.02 from nominal.

But it’s perfectly usable as-is.

I decided to read the step densities with the new Dektronics Printalyzer Densitometer. The Dektronics densitometer agrees with the calibration tablet that came with it. In reading the Stouffer tablet I took three measurements across each step and recorded the average. At each step, out of each of the three measurements, never did the measurement differ by more than 1/100s, two or three steps on the tablet read the same all the way across the step, but most had two measurements that agreed and one measurement that was different by 1/100s. Now, I don't know if the Dektronics device is supposed to match the Stouffer tablet measurements better than it does or not, I guess it would be nice.........however, all of the Dektronics step measurements are still within .02 of the preferred increment of .15..........

I guess, there can only be one actual correct denisity for each step, perhaps I have to take the point of view that the more correct density is from the Stouffer measurements, they're supposed to be a professional outfit with high dollar equipment.

I guess, there can only be one actual correct denisity for each step, perhaps I have to take the point of view that the more correct density is from the Stouffer measurements, they're supposed to be a professional outfit with high dollar equipment.

Last edited:

Any possibility that the step wedge is not the problem?

relistan

Member

I guess, there can only be one actual correct denisity for each step, perhaps I have to take the point of view that the more correct density is from the Stouffer measurements, they're supposed to be a professional outfit with high dollar equipment.

Top shelf equipment used professionally will need regular calibration to be correct. Most of us don't need and don't want to pay for that. So in general I'd look for consistency from each piece of equipment against the Stouffer wedge rather than correct absolute values. Since you have two sets of measurements against the Stouffer wedge that don't match, I'd be more suspicious of your equipment than the density of the actual wedge. This being slightly out of calibration at this small level seems totally reasonable to me.

I talked with Stouffer today........I learned that the density increment tolerance is not uniform, the tolerances are:

Steps 1-4 .02

Steps 5-7 .03

Step 8 .04

Step 9 .05

Steps 10-11 .06

Steps 12-13 .07

Step 14 .08

Steps 15-16 .09

Steps 17-21 .10

Given this, I've no real issue with incremental step densities on this step wedge. They're all within .02, with exception of step 13, which is at .03. Regarding the black spots, I'm going to send them a picture of it this evening when I get home from work.

Steps 1-4 .02

Steps 5-7 .03

Step 8 .04

Step 9 .05

Steps 10-11 .06

Steps 12-13 .07

Step 14 .08

Steps 15-16 .09

Steps 17-21 .10

Given this, I've no real issue with incremental step densities on this step wedge. They're all within .02, with exception of step 13, which is at .03. Regarding the black spots, I'm going to send them a picture of it this evening when I get home from work.

I've been struggling with transmission readings of my calibrated Stouffer wedge using the Printalyzer Densitometer for several days. Here's the problem:

I first plotted Stouffer's measurements (blue) against the Printalyzer Densitometer measurements (red). When I saw the large difference, I wondered which line is correct, so I measured the densities using my easel meter purchased from Darkroom Automation (which on Photrio is @Nicholas Lindan). That is the green line, which is significantly different from the other two! Wondering which line is correct, I enhanced the software in my LED-head enlarger controller to function as a densitometer, using the meter only to indicate whether the light it sees is equal to the initial reading. Any meter can do that correctly, no matter how inaccurate it is. That yielded the yellow line.

The enlarger measurements and Darkroom Automation meter measurements are nearly identical, so I think those are the true densities.

I'm seeing signs that Stouffer has become sloppy. Their calibrated (measured) densities don't agree with anything. The Zone chips I bought from them were much too light. And now spots on a wedge! I suspect their "calibrated" measurements used a densitometer that had drifted out of calibration.

Here are measurements of the control strip that came with the Printalyzer Densitometer:

The Printalyzer Densitometer agrees closely with its control strip, but both are significantly below the measurements from the Darkroom Automation meter. I suspect that the densitometer was calibrated to a defective control strip. BTW, step 1 was difficult to measure due to its high density, and I suspect my work-around caused the measurement to be off.

Have I made a mistake?

Darkroom Automation states that its meter also functions as a densitometer, so I'm not abusing the meter. And my enlarger-based measurements agree with it. That's strong evidence that both Stouffer and the Printalyzer Densitometer are wrong. But what's the chance that both are wrong? That seems implausible, but that's what my data says. Unless I goofed both the DA and enlarger measurements.

Mark

I first plotted Stouffer's measurements (blue) against the Printalyzer Densitometer measurements (red). When I saw the large difference, I wondered which line is correct, so I measured the densities using my easel meter purchased from Darkroom Automation (which on Photrio is @Nicholas Lindan). That is the green line, which is significantly different from the other two! Wondering which line is correct, I enhanced the software in my LED-head enlarger controller to function as a densitometer, using the meter only to indicate whether the light it sees is equal to the initial reading. Any meter can do that correctly, no matter how inaccurate it is. That yielded the yellow line.

The enlarger measurements and Darkroom Automation meter measurements are nearly identical, so I think those are the true densities.

I'm seeing signs that Stouffer has become sloppy. Their calibrated (measured) densities don't agree with anything. The Zone chips I bought from them were much too light. And now spots on a wedge! I suspect their "calibrated" measurements used a densitometer that had drifted out of calibration.

Here are measurements of the control strip that came with the Printalyzer Densitometer:

The Printalyzer Densitometer agrees closely with its control strip, but both are significantly below the measurements from the Darkroom Automation meter. I suspect that the densitometer was calibrated to a defective control strip. BTW, step 1 was difficult to measure due to its high density, and I suspect my work-around caused the measurement to be off.

Have I made a mistake?

Darkroom Automation states that its meter also functions as a densitometer, so I'm not abusing the meter. And my enlarger-based measurements agree with it. That's strong evidence that both Stouffer and the Printalyzer Densitometer are wrong. But what's the chance that both are wrong? That seems implausible, but that's what my data says. Unless I goofed both the DA and enlarger measurements.

Mark

- Joined

- Aug 22, 2006

- Messages

- 1,524

- Format

- Multi Format

I first plotted Stouffer's measurements (blue) against the Printalyzer Densitometer measurements (red). When I saw the large difference, I wondered which line is correct...

Hi, looks to me like the main differences are in "contrast," meaning the slopes are different. This kinda suggests to me that it might be an issue with the optical geometry, along the lines of a Callier Q coefficient, or whatever they're calling it. This has to do with the silver in the step wedge slightly scattering light coming through it, so you can get a different measurement depending on exactly how you "collect" the light to be measured.

I'm thinking that the typical densitometer uses a single diffusion (but might be double diffuse?).

I don't know exactly how you're reading YOUR densities, but if it's all through the enlarger it might be interesting if you could throw some heavy diffusion in there (mimicking a diffusion enlarger). It might come down and match the Stouffer readings.

[...] it might be interesting if you could throw some heavy diffusion in there (mimicking a diffusion enlarger).

I forgot to mention that this is a diffusion enlarger. Light from the LEDs in the LED-head pass through a big diffuser.

I just finished a new set of measurements by changing head-height to keep illumination on the meter the same in successive steps, and then computing densities using the inverse-square law. The result agrees with the Darkroom Automation meter and the other enlarger-based measurements (green and yellow lines in 1st graph).

Mark

- Joined

- Aug 22, 2006

- Messages

- 1,524

- Format

- Multi Format

The result agrees with the Darkroom Automation meter...

Does the Darkroom Automation meter use diffusion?

tom williams

Subscriber

Thanks for this data.I talked with Stouffer today........I learned that the density increment tolerance is not uniform, the tolerances are:

Steps 1-4 .02

Steps 5-7 .03

Step 8 .04

Step 9 .05

Steps 10-11 .06

Steps 12-13 .07

Step 14 .08

Steps 15-16 .09

Steps 17-21 .10

Given this, I've no real issue with incremental step densities on this step wedge. They're all within .02, with exception of step 13, which is at .03. Regarding the black spots, I'm going to send them a picture of it this evening when I get home from work.

Here's the graph with an added line for measurements using the inverse-square law (i.e., moving the enlarger-head down and measuring heights).

As you can see, the new line (dark red/magenta) agrees with the Darkroom Automation meter and the enlarger-match measurements. So three methods of measuring densities are telling us that Stouffer's densitometer was miscalibrated and there's a problem with the control strip for the Printalyzer Densitometer. I can work around the PD error by multiplying its measurements by 1.08, but I plan to contact Derek -- I'd like to hear his assessment of this disparity and my measurements.

I'm still appalled at those spots that Stouffer had on the OP's wedge. How did that get out the door?

Mark

As you can see, the new line (dark red/magenta) agrees with the Darkroom Automation meter and the enlarger-match measurements. So three methods of measuring densities are telling us that Stouffer's densitometer was miscalibrated and there's a problem with the control strip for the Printalyzer Densitometer. I can work around the PD error by multiplying its measurements by 1.08, but I plan to contact Derek -- I'd like to hear his assessment of this disparity and my measurements.

I'm still appalled at those spots that Stouffer had on the OP's wedge. How did that get out the door?

Mark

I'm still appalled at those spots that Stouffer had on the OP's wedge. How did that get out the door?

I've let them know in my email to them when I sent the picture of the spots that I want to return it for a clean step wedge. I'm interested in what Derik may have to say regarding your claims that the Printalyzer Densitometer (P-D) calibration strip is in error. The P-D readings I get from the Stouffer tablet are all well within Stouffer's own stated tolerances that I learned about today and shown in my post #16.

- Joined

- Feb 9, 2010

- Messages

- 9,463

- Format

- 4x5 Format

Darkroom Automation’s meter is an easel meter. It introduces flare. Unless you held the step wedge against the sensor. Even if you mask the wedge steps carefully to avoid stray light, you would have a hard time getting a flare-free reading.

dkonigs

Subscriber

Okay, so there's a lot to unpack here, so I'll start by throwing a few comments out there. I'll probably miss something buried in the details of one of the above posts, but I'm going to try to offer some input.

Most (now-discontinued) high-end commercial densitometers have an accuracy specification of +/- 0.02D or worse, depending on the density of the target. I have no idea what Stouffer uses for measuring their transmission targets, as they only mention their reflection instrument on the website.

A typical bench-top densitometer can only be as good as its calibration references, and there are only so many ways to actually get such references these days. The only sources I'm personally aware of for this are Stouffer, Acurad, and NIST. From my own conversations, I've been able to gather that Stouffer claims their calibrations are NIST traceable, and that Acurad does something proprietary with a collection of internal reference densitometers specific to whichever device they're making a strip for. In my own experiments, Stouffer and Acurad references are clearly not calibrated to the same upstream reference.

If you want a trustworthy "gold standard", I think your only choice is to buy a NIST Photographic Film Step Tablet Transmission Density Standard (38120C). Link here. Be warned, it costs about $5k. They also don't specify on the website what documents it comes with, or what standard it itself is measured against. It is also my understanding that the NIST reference standard is actually manufactured by Stouffer, but measured by NIST.

The densitometer standard (ISO 5-3:2009, formerly known as ANSI PH 2.18) actually specifies spectral conditions for density measurements. Some densitometers follow them, some don't, and some are vague about it. If you measure materials with different spectral properties, or with different light sources, variations are absolutely possible. The effect of this should be minimal with normal B&W film, but could be quite pronounced with color film (even on a gray target). It may also lead to a big difference between under-the-enlarger measurements and measurements from densitometers that provide their own light source.

The developer of the enLARGE iOS app goes on at great lengths on his website in trying to explain how the relationship between enlarger height and print density cannot simply be explained by the inverse square law alone. I have no idea if his explanations make any sense, but back when he was bragging about the app on Facebook I did a lot of my own experiments and confirmed that the relationship is more complex than a simple calculation.

Finally, if you want to compare the performance of two different densitometers, you absolutely have to calibrate them against the same reference strip. Otherwise, you're not comparing the densitometers, you're just comparing the reference materials you have paired with them.

I should also point out that when you measure a reference strip, you need to measure it in the correct orientation. This orientation will depend on the specific densitometer you are using, but is typically whatever has the emulsion site facing the sensor. On the X-Rite 8xx series, this is typically emulsion-down. On most others, this is typically emulsion up.

Okay, now below a break for some visual separation...

When measuring a transmission step wedge, it is important to always measure from the same spot. One thing Stouffer does not do, is actually tell you which spot on their wedge the calibration values they provide were measured from. If you measure different points along the same patch, especially for the darker patches, you absolutely will see a difference. When I use mine, I always try to aim for measuring from dead center, and only from dead center.

Now, if you want to know where the Printalyzer Densitometer reference strips come from, its all ultimately traceable back to Stouffer. But for the specific process, it works something like this:

First, I calibrate a reference unit to the best of my ability. This begins with something I call "slope calibration", which is a process that uses a calibrated Stouffer T2120C (21-step wedge) to correct for any linearity issues with the sensor. The way the data is processed, minor step-to-step variations shouldn't cause a problem here. The result is basically coefficients for a correction polynomial.

After this, I perform normal calibration on the unit. That involves measuring an open aperture, and then measuring dead-center on patch 4 of a calibrated Stouffer T5100C (5-step wedge).

Second, I take a fresh unlabeled Stouffer T5100 transmission wedge, place it in a holder that covers up where the label would go, and use the reference unit to measure the center of the remaining exposed area of each step. I then log all the data, print a custom label, and apply it.

Phew... I hope that was enough to help add something to the conversation. I'll continue to monitor this thread and may chime in again as necessary.

Most (now-discontinued) high-end commercial densitometers have an accuracy specification of +/- 0.02D or worse, depending on the density of the target. I have no idea what Stouffer uses for measuring their transmission targets, as they only mention their reflection instrument on the website.

A typical bench-top densitometer can only be as good as its calibration references, and there are only so many ways to actually get such references these days. The only sources I'm personally aware of for this are Stouffer, Acurad, and NIST. From my own conversations, I've been able to gather that Stouffer claims their calibrations are NIST traceable, and that Acurad does something proprietary with a collection of internal reference densitometers specific to whichever device they're making a strip for. In my own experiments, Stouffer and Acurad references are clearly not calibrated to the same upstream reference.

If you want a trustworthy "gold standard", I think your only choice is to buy a NIST Photographic Film Step Tablet Transmission Density Standard (38120C). Link here. Be warned, it costs about $5k. They also don't specify on the website what documents it comes with, or what standard it itself is measured against. It is also my understanding that the NIST reference standard is actually manufactured by Stouffer, but measured by NIST.

The densitometer standard (ISO 5-3:2009, formerly known as ANSI PH 2.18) actually specifies spectral conditions for density measurements. Some densitometers follow them, some don't, and some are vague about it. If you measure materials with different spectral properties, or with different light sources, variations are absolutely possible. The effect of this should be minimal with normal B&W film, but could be quite pronounced with color film (even on a gray target). It may also lead to a big difference between under-the-enlarger measurements and measurements from densitometers that provide their own light source.

The developer of the enLARGE iOS app goes on at great lengths on his website in trying to explain how the relationship between enlarger height and print density cannot simply be explained by the inverse square law alone. I have no idea if his explanations make any sense, but back when he was bragging about the app on Facebook I did a lot of my own experiments and confirmed that the relationship is more complex than a simple calculation.

Finally, if you want to compare the performance of two different densitometers, you absolutely have to calibrate them against the same reference strip. Otherwise, you're not comparing the densitometers, you're just comparing the reference materials you have paired with them.

I should also point out that when you measure a reference strip, you need to measure it in the correct orientation. This orientation will depend on the specific densitometer you are using, but is typically whatever has the emulsion site facing the sensor. On the X-Rite 8xx series, this is typically emulsion-down. On most others, this is typically emulsion up.

Okay, now below a break for some visual separation...

When measuring a transmission step wedge, it is important to always measure from the same spot. One thing Stouffer does not do, is actually tell you which spot on their wedge the calibration values they provide were measured from. If you measure different points along the same patch, especially for the darker patches, you absolutely will see a difference. When I use mine, I always try to aim for measuring from dead center, and only from dead center.

Now, if you want to know where the Printalyzer Densitometer reference strips come from, its all ultimately traceable back to Stouffer. But for the specific process, it works something like this:

First, I calibrate a reference unit to the best of my ability. This begins with something I call "slope calibration", which is a process that uses a calibrated Stouffer T2120C (21-step wedge) to correct for any linearity issues with the sensor. The way the data is processed, minor step-to-step variations shouldn't cause a problem here. The result is basically coefficients for a correction polynomial.

After this, I perform normal calibration on the unit. That involves measuring an open aperture, and then measuring dead-center on patch 4 of a calibrated Stouffer T5100C (5-step wedge).

Second, I take a fresh unlabeled Stouffer T5100 transmission wedge, place it in a holder that covers up where the label would go, and use the reference unit to measure the center of the remaining exposed area of each step. I then log all the data, print a custom label, and apply it.

Phew... I hope that was enough to help add something to the conversation. I'll continue to monitor this thread and may chime in again as necessary.

| Photrio.com contains affiliate links to products. We may receive a commission for purchases made through these links. To read our full affiliate disclosure statement please click Here. |

PHOTRIO PARTNERS EQUALLY FUNDING OUR COMMUNITY:  |