DREW WILEY

Member

- Joined

- Jul 14, 2011

- Messages

- 14,656

- Format

- 8x10 Format

The matrix film that Bettina Haneke uses didn't come from Ekfe, and is an entirely different formulation optimized for blue laser exposure. And no, it's not available to the public. It's possible that there was a preliminary version which did come from Efke, but I'm not going to dig through my old notes. All this didn't involve investors, but a substantial university grant, unlikely to be repeated. Any serious DT revival is likely going to be reliant on some kind of philanthropic interest.

Kodak materials weren't as consistent as you imply. Towards the end, as the older technicians were being replaced by lesser experienced ones, not only was there a flawed batch of yellow dye which got out (not to mention the flip flop in its variations), but also some lesser quality receiver paper. Matrix film was being coated with especially old machinery.

I'm aware of the mottle you describe with the Efke product. It probably wouldn't bother someone looking at a larger print, but might be slightly annoying in an 8x10 contact print. I experimented with it using using both my own variation of Wash-Off relief and with the Kodak development system. But I don't pretend to be anything more than a kindergarten level DT printer still just learning the piano chords.

The swelling issue of the Efke product can be overcome. But hopefully, if there ever again is a production run of Matrix film, several issues could be redressed.

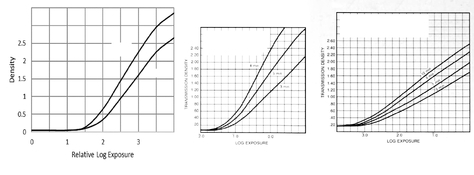

The more relevant Kodak chemists and technicians who were involved during its heyday are no longer around. But I still contend that, going forward, if possible it would make more sense to develop a product with a more cooperative toe needing less highlight masking. Much of this problem has been overcome by the special curve-restructured profiles made possible by the laser exposure route of Bettina, as well as the film-recorder re-profiling separation negs which Jim Browning employs. But for those of us who prefer a traditional darkroom route, other tricks must be used.

Kodak materials weren't as consistent as you imply. Towards the end, as the older technicians were being replaced by lesser experienced ones, not only was there a flawed batch of yellow dye which got out (not to mention the flip flop in its variations), but also some lesser quality receiver paper. Matrix film was being coated with especially old machinery.

I'm aware of the mottle you describe with the Efke product. It probably wouldn't bother someone looking at a larger print, but might be slightly annoying in an 8x10 contact print. I experimented with it using using both my own variation of Wash-Off relief and with the Kodak development system. But I don't pretend to be anything more than a kindergarten level DT printer still just learning the piano chords.

The swelling issue of the Efke product can be overcome. But hopefully, if there ever again is a production run of Matrix film, several issues could be redressed.

The more relevant Kodak chemists and technicians who were involved during its heyday are no longer around. But I still contend that, going forward, if possible it would make more sense to develop a product with a more cooperative toe needing less highlight masking. Much of this problem has been overcome by the special curve-restructured profiles made possible by the laser exposure route of Bettina, as well as the film-recorder re-profiling separation negs which Jim Browning employs. But for those of us who prefer a traditional darkroom route, other tricks must be used.

Last edited: