I will measure temperature and take many other metrics once I get this finished.

-

Welcome to Photrio!Registration is fast and free. Join today to unlock search, see fewer ads, and access all forum features.Click here to sign up

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making an UV enlarger

-

A

- Thread starter Uncle Goose

- Start date

Recent Classifieds

-

For Sale Canon RF 600mm f11, RF 100-400 Lenses

- Started by Jon Shiu

-

For Sale Fujifilm MAXIMA Glossy RA-4 Paper; Packs of 16x20 Sheets

- Started by Aidan Sciortino

-

Sold 1924 Carl Zeiss Jena 150mm f4.5 Lens in dial Compur

- Started by Jon Shiu

-

Found Plastic 5x7 film holders (Fidelity, Lisco)

- Started by blee1996

-

Want to Buy WTB: Digital timer for an enlarger

- Started by Terrence Brennan

Forum statistics

Yesterday, I did my first full systems test of a Douwe-style enlarger. Thanks @douwe for guidance in getting the right parts. It is indeed a very efficient design, 40W electrical power give me about 4 times the exposure time I need for contact printing in my 360W fluorescent setup. The LED temperature stays below 50C and the negative does not get much more than hand warm in 20 minutes ( about the time needed to expose a fairly dense negative at 11x14). Next I need to do something about stray light and focusing.

Yesterday, I did my first full systems test of a Douwe-style enlarger. Thanks @douwe for guidance in getting the right parts. It is indeed a very efficient design, 40W electrical power give me about 4 times the exposure time I need for contact printing in my 360W fluorescent setup. The LED temperature stays below 50C and the negative does not get much more than hand warm in 20 minutes ( about the time needed to expose a fairly dense negative at 11x14). Next I need to do something about stray light and focusing.

Congrats! Did you manage to get the same LED what Douwe used? If so, could you share the product code. I looked at the AliExpress many times but couldn't figure out the correct variant for the LED.

As my traditional enlarger doesn't blast that much UV I have focused by eye (without grain focuser). In previous tests I actually removed the light source from enlarger and used my phones flash light to focus. So I think there could be two possibilities for focusing (safely). Either use PWM or some other dimming method to cut down the intensity of UV light - or add "focusing" white LED near the UV led and use that to focus?

Here it goes:

First real print from 6x6 negative, enlarged to 10x10 inches. The sensitizer is old and has some fog/clearing issue and the coating was sloppy (I just wanted to see the enlarger work)

As far as focusing goes, I used white printer paper since as @douwe explained in his podcast, they have brighteners which fluoresce under UV, i.e. they convert UV to white light. I need to get some way to magnify this image so that I can see the grain... Focusing with white light itself probably requires to carefully think about focus shift with wavelength.

First real print from 6x6 negative, enlarged to 10x10 inches. The sensitizer is old and has some fog/clearing issue and the coating was sloppy (I just wanted to see the enlarger work)

As far as focusing goes, I used white printer paper since as @douwe explained in his podcast, they have brighteners which fluoresce under UV, i.e. they convert UV to white light. I need to get some way to magnify this image so that I can see the grain... Focusing with white light itself probably requires to carefully think about focus shift with wavelength.

Petrochemist

Member

That depends very much on the enlarger lens. The aperture will reduce light in just the same way as it does for visual light but as commented up thread (9 years ago) glass absorbs UV.How much does enlarger lens cut down the light? For example if aperture is at f8? Of course compared to direct UV array or "panel" light.

My 80mm metal bodied El-Nikkor was brought for UV photography, tests on the spectrometer at work show it transmits 54% of the light at 350nm, while most other lenses are nearer 10% and a few are below 0.5%.

This lens also has a reputation for being nearly parfocal across the usable UV/visual/NIR range so may allow safe focusing in visual light, before changing light sources for the exposure. Some degree of focus shift will probably still occur, but it should be possible to correct for that.

I would expect contact printing to be much easier, but that doesn't help if you want an enlargement!

All the UV lamps I've seen available to the public are relatively low intensity, but modifying a flash gun can give a high intensity UV source - 2 or 3 flashes might be enough to complete the print. A few test strips should home in on the right exposure relatively quickly.

Here it goes:

View attachment 288100

First real print from 6x6 negative, enlarged to 10x10 inches. The sensitizer is old and has some fog/clearing issue and the coating was sloppy (I just wanted to see the enlarger work)

As far as focusing goes, I used white printer paper since as @douwe explained in his podcast, they have brighteners which fluoresce under UV, i.e. they convert UV to white light. I need to get some way to magnify this image so that I can see the grain... Focusing with white light itself probably requires to carefully think about focus shift with wavelength.

Well done! Beautiful print.

If there is shift in focus based on wavelength, based on my experience it is really small. I focused my salt prints by eye and those look pretty sharp even that way. I used same paper type as "reflector" on base board.

edit: because of the alternative process looks I wouldn't be worried of needing super sharpness in prints.

Yesterday, I did my first full systems test of a Douwe-style enlarger. Thanks @douwe for guidance in getting the right parts. It is indeed a very efficient design, 40W electrical power give me about 4 times the exposure time I need for contact printing in my 360W fluorescent setup. The LED temperature stays below 50C and the negative does not get much more than hand warm in 20 minutes ( about the time needed to expose a fairly dense negative at 11x14). Next I need to do something about stray light and focusing.

Congratulations! I'm very happy you managed to put it together and get a nice first print out of it. Well done!

I've not visited this thread for a couple weeks and a lot of ideas were posted in the meantime (Cool!). Just a couple points, to share some lessons I learned over the past months:

- Dust really isn't a very large problem in the condensor enlarger, UV-light makes dust particles light up in purple so you can see them on the negative carrier and wipe them away before printing.

- I don't have any heat problems, I expose between 20-45min for an 8x enlargement of 6x7 negatives. I chose optical efficiency over power.

- The best lens I found so far is a kodak 100mm enlarging ektar, it balances sharpness and transmission very well. I get about 50% more UV through that lens than through a 100mm componon-s.

- Since printing with UV is all about managing transmission, don't forget about the film base material. Kodak can have very dense base material, whereas rollei has a few PET based films that transmit a lot more light!

- Mike Ware's new cyanotype formulation is more sensitive than regular cyanotype emulsion, which speeds up printing. (It also has much lower contrast. Please omit the dichromate from the formulation for your own safety)

Indeed, but this is limited to TMax 100 in 120 and sheet film formats, which blocks UV by 3 to 3.5 stops (!!) All other films are more or less similar in terms of UV transmission.Kodak can have very dense base material

Certainly. It requires negatives that are also suitable for salted paper prints, with the difference that new cyanotype is a lot faster than salted paper.Mike Ware's new cyanotype formulation is more sensitive than regular cyanotype emulsion, which speeds up printing. (It also has much lower contrast.

What would be comparable exposures for New Cyanotype vs Salt from say, HP5+ negatives?

2x, 3x or 4x faster?

Unfortunately my testing has stopped as the CC PSU has failed for the 500W LED and I am waiting on the replacement from SatisLED, but I have overcome completely the temperature problem, but at a loss of Lumen power I hope will be acceptable.

Thanks, Alan

2x, 3x or 4x faster?

Unfortunately my testing has stopped as the CC PSU has failed for the 500W LED and I am waiting on the replacement from SatisLED, but I have overcome completely the temperature problem, but at a loss of Lumen power I hope will be acceptable.

Thanks, Alan

Something like 4-8x faster.What would be comparable exposures for New Cyanotype vs Salt from say, HP5+ negatives?

2x, 3x or 4x faster?

That's a tricky piece of kit to begin with. High current levels; we're probably talking about 10-15A, modulated fairly rapidly. Requires some decent electrical engineering to get that to work reliably in the long term.the CC PSU has failed for the 500W LED

-

- radiant

- Deleted

-

- radiant

- Deleted

Ethan Brossard

Member

I've been following Alan's UV enlarger progress on facebook, and he directed me to this thread yesterday. I'm in process of designing an 8x10 LED enlarger I hope to build soon, and since reading this thread and talking with Alan, I'm wondering if it may be possible to make a UV head for it, or maybe even have UV LEDs in the same head as I would use for standard black and white printing. In thinking about this, I have a few questions for you guys.

My first question is about enlarging lenses. In the podcast you were on Douwe, you mentioned that old enlarging lenses are best because they are optimized for near UV light. I have a newer rodagon 300mm, which I assume is optimized for color enlarging. Assuming that would not be ideal, do you have any recommendations for what series of lenses I should be looking for? I've got a 30cm Zeiss Jena Apo Tessar, which being an uncoated 4 element lens would work, but it's only f/9, which is much smaller than the rodagon's f/5.6

My second question is about how much power I should want for the light source. It sounds like all of you used 40W UV LEDs, for 6x6 and 6x7 negatives. For an 8x10 negative which is roughly 20 times the area, some quick math gives me 800 watts as the power needed. 800 watts is quite a bit though, so would it be feasible to use 400 watts or something smaller? how long are your enlargement times with the 40 watt sources?

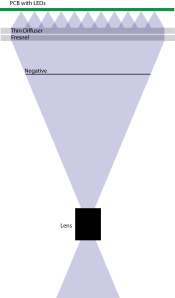

The last thing I'm wondering about is how to design the light source. It sounds like using a condenser is optimal as less light is lost to reflections. A traditional condenser requires a point source though, and if I need a 400 watt or 800 watt source, a point source that powerful probably doesn't exist. I had an idea on how it may be possible to solve that issue, I'd appreciate your input though. The idea is basically a hybrid condenser diffusion enlarger. I'm thinking I could have a bunch of UV LEDs on a pcb, a diffusion panel beneath it to even the light, and then a fresnel lens beneath that to focus the light onto the lens. Could that work, or would too much light be lost in the diffusion glass? below is a sketch of what I'm thinking.

My first question is about enlarging lenses. In the podcast you were on Douwe, you mentioned that old enlarging lenses are best because they are optimized for near UV light. I have a newer rodagon 300mm, which I assume is optimized for color enlarging. Assuming that would not be ideal, do you have any recommendations for what series of lenses I should be looking for? I've got a 30cm Zeiss Jena Apo Tessar, which being an uncoated 4 element lens would work, but it's only f/9, which is much smaller than the rodagon's f/5.6

My second question is about how much power I should want for the light source. It sounds like all of you used 40W UV LEDs, for 6x6 and 6x7 negatives. For an 8x10 negative which is roughly 20 times the area, some quick math gives me 800 watts as the power needed. 800 watts is quite a bit though, so would it be feasible to use 400 watts or something smaller? how long are your enlargement times with the 40 watt sources?

The last thing I'm wondering about is how to design the light source. It sounds like using a condenser is optimal as less light is lost to reflections. A traditional condenser requires a point source though, and if I need a 400 watt or 800 watt source, a point source that powerful probably doesn't exist. I had an idea on how it may be possible to solve that issue, I'd appreciate your input though. The idea is basically a hybrid condenser diffusion enlarger. I'm thinking I could have a bunch of UV LEDs on a pcb, a diffusion panel beneath it to even the light, and then a fresnel lens beneath that to focus the light onto the lens. Could that work, or would too much light be lost in the diffusion glass? below is a sketch of what I'm thinking.

Attachments

Ethan, I'll leave other to answer more but I would bet on you CZ Jena as being good for passing UV - All the old (19460's or before) uncoated lenses (Wolensack/Nikon/Componon/Rodenstock) pass more UV than anything newer. Most of the coated lenses are blocking UV - I used an old Nikon metal 80mm in testing and that was supposed to pass 90%, UV - and it was one of the best - An old Componon 210 c1961 (non S) apparently covers 18x24 although not by Nikon specs, and it too was good at passing UV. I will (have already) look into Flouride lenses and *may* be able to get a 150mm coverage for a one off price if USD 1500 which is horrid, but I am guessing some people will not mind that cost if they can print 16x20 without internegatives. Once I get the replacement cc PSU I will be able to measure and test more, and I will post results of testing, good or bad. Douwe get 20 mins exposures on New Cyanotype and I hear that process is 4x to 8x slower than Salt where I will test, so I hope some the extra power I get might be transmitted and give me a result around 30 minutes. I live in hope....... Previously I contacted via the enlarger with 20 mins time and that was about x1 underexposed so........

Ethan, a hybrid enlarger will be much closer in efficiency to a diffusion enlarger than to a condensor enlarge. The key quantity is the emittance of your light source. Emittance being the product of the area of the light source times the solid angle it emits into. It sets a limit to how effectively it can be focused. You need to able to focus the light source within the entrance pupil of your enlarger lens. The diffusor increases emittance by a lot (that is what it is designed for).

However, I think your calculation is maybe not quite right: what sets the amount of light you need is the size of the print and not the size of the negative. So if you wanted to a 11x14 print than 40W will suffice for any size of negative. If you do 22x28 print you need 4x40W asf. Since typically one doesn't enlarge 8x10 negatives by the same factor as 6x7 ones, it's not quite that bad. Also the focal length of the enlarger lens has to go up in proportion to the negative diagonal. In turn, for fixed f-number of your lens the entrance pupil grows., so maybe Douwe's design can be "simply" scaled up to 8x10 (notwithstanding huge Fresnel lenses etc.)

However, I think your calculation is maybe not quite right: what sets the amount of light you need is the size of the print and not the size of the negative. So if you wanted to a 11x14 print than 40W will suffice for any size of negative. If you do 22x28 print you need 4x40W asf. Since typically one doesn't enlarge 8x10 negatives by the same factor as 6x7 ones, it's not quite that bad. Also the focal length of the enlarger lens has to go up in proportion to the negative diagonal. In turn, for fixed f-number of your lens the entrance pupil grows., so maybe Douwe's design can be "simply" scaled up to 8x10 (notwithstanding huge Fresnel lenses etc.)

Just for reference: my approximately A4 size salt print take 4-5 hours to expose on Nikon 50mm lens at f2.8 and with 50W UV led. UV-index is pretty low, maybe 0.2, 0.3?

My 5x7" contact salt prints with 15W of led strip from 30cm distance take about 20-30 minutes of exposure. If I remember UV-index was 0.8 for this.

My 5x7" contact salt prints with 15W of led strip from 30cm distance take about 20-30 minutes of exposure. If I remember UV-index was 0.8 for this.

Ethan Brossard

Member

You're absolutely right! Thanks for pointing that out. I'd like to make at largest 32x40 prints, but calculating for that rather than the negative size I only need ~300 watts, which is much more reasonable. I can probably use a 300 watt LED similar to the one Alan used in his design, with a pair of 12x12 fresnel lenses or something along those lines. Thanks!Ethan, a hybrid enlarger will be much closer in efficiency to a diffusion enlarger than to a condensor enlarge. The key quantity is the emittance of your light source. Emittance being the product of the area of the light source times the solid angle it emits into. It sets a limit to how effectively it can be focused. You need to able to focus the light source within the entrance pupil of your enlarger lens. The diffusor increases emittance by a lot (that is what it is designed for).

However, I think your calculation is maybe not quite right: what sets the amount of light you need is the size of the print and not the size of the negative. So if you wanted to a 11x14 print than 40W will suffice for any size of negative. If you do 22x28 print you need 4x40W asf. Since typically one doesn't enlarge 8x10 negatives by the same factor as 6x7 ones, it's not quite that bad. Also the focal length of the enlarger lens has to go up in proportion to the negative diagonal. In turn, for fixed f-number of your lens the entrance pupil grows., so maybe Douwe's design can be "simply" scaled up to 8x10 (notwithstanding huge Fresnel lenses etc.)

Ethan Brossard

Member

that's pretty slow, what wavelength is your LED? I read that though cyanotypes and most alt process are fastest around 365nm processes like kallitypes and platinum/palladium prints a source closer to blue is faster. Can anyone here verify if that is true or not? I'm hoping it is, as I'd like to do platinum / palladium prints with this, and looking at the high power UV LED units Alan used, one which peaks at 395nm is 1/5 the cost as one which peaks at 365Just for reference: my approximately A4 size salt print take 4-5 hours to expose on Nikon 50mm lens at f2.8 and with 50W UV led. UV-index is pretty low, maybe 0.2, 0.3?

My 5x7" contact salt prints with 15W of led strip from 30cm distance take about 20-30 minutes of exposure. If I remember UV-index was 0.8 for this.

that's pretty slow, what wavelength is your LED? I read that though cyanotypes and most alt process are fastest around 365nm processes like kallitypes and platinum/palladium prints a source closer to blue is faster. Can anyone here verify if that is true or not? I'm hoping it is, as I'd like to do platinum / palladium prints with this, and looking at the high power UV LED units Alan used, one which peaks at 395nm is 1/5 the cost as one which peaks at 365

Yes, that is slow. I think my led is somewhere 395. My UV enlarger is just a regular enlarger with condenser lens fitted with COB UV. So it is by design very poor by efficiency.

I've done maybe about 10 prints now with it and I have to say that the long exposure isn't a problem at all. I just leave it alone and get one print done per day. That would be enough anyways. Also the slowness makes it really care free. My increments in time are 1-2 hours, so it is really easy to control. I just set a timer on my watch and forget it. Quite relaxed stuff anyways. Sensitizing and washing,fixing,washing paper is much much more annoying.

Not sure where you read this and whether it's true or not. Frankly I'd expect that in principle the shorter the wavelength, the higher the printing speed as shorter wavelength light simply carries more energy. However, there's a tradeoff in the sense that UV blocking by all materials in the optical path (ultimately also the atmosphere if you get to low enough wavelengths) becomes and issue. I have the impression that the 365 wavelength peak sensitivity of alt. processes is not necessarily very well substantiated in terms of physics and that it's a combination of testing methods, definitions and practical availability of materials/light sources that has led to this understanding.I read that though cyanotypes and most alt process are fastest around 365nm processes like kallitypes and platinum/palladium prints a source closer to blue is faster.

One of the best resources out there, at least with easy availability, is the well-known UnblinkingEye page written by Sandy King on the subject: https://unblinkingeye.com/Articles/Light/L2/l2.html (note that there's also a page 1 of the article, but I linked directly to the 'dirty pictures').

While it's one of the few (and perhaps the only one) true comparisons of several light sources and processes, and therefore of great value, methodologically it's not bullet-proof. Likely it was never intended to be, and instead was intended (and succeeded!) in giving practical recommendations based on empirical evidence to printers. Since the article was published before UV leds became commonly available, it doesn't say anything about them. Indeed it would be interesting to revisit the topic with these new light sources at hand, which would be particularly interesting due to their inherently narrow emission peak compared to UV tubes, let alone HMI's.

Long story short, if you ask where the optimal sensitivity of your alt. process is, I would say "the shortest wavelength that does not suffer from severe attenuation". That likely happens to be in the 350 ~ 375nm range. This will give you 'the most exposure' per Watt of electrical power you throw at it.

If you ask, what gives me the most exposure per dollar value, then it's a different story and you'll end up right at the 395nm spot where entry-level UV leds are the cheapest. Note that this is a rather sensible question to ask given the price differential between 365nm and ~400 nm leds. If a 365nm led costs 5x as much as a similarly powered 400nm one, but only gives one stop of speed advantage (if that!), it'd still make sense to go for the slower but cheaper 400nm ones (and invest some cash in better cooling).

Perhaps that was a slip of the pen, but New Cyanotype is actually a few stops faster than salt. The difference is something like 2~3 stops. So if you need a 20 minute exposure for New Cyanotype, count on a 80 ~160 minute exposure for salted paper.New Cyanotype and I hear that process is 4x to 8x slower than Salt

Yes, that could work. But note that you'd need to use a metal-core PCB for this. No plain old FR4, as it won't allow for sufficiently easy heat dissipation. It seems that e.g. JLCPCB offers an affordable aluminium option these days. The odds that the appropriate high-power UV leds are in their catalog are pretty slim, so you'd have to solder them onto the PCB yourself. Note that this will require some kind of reflow setup; the cheapest of which is one of those hot plates that are in vogue these days (and work surprisingly well). I did this for my RGB LED enlarger head (360W on 10x15cm PCB, so a little over 2W/cm2).I'm thinking I could have a bunch of UV LEDs on a pcb

By far the easiest approach is to take a COB led or even a ready-made product based on a COB led and take care of the cooling/heat dissipation problem. Discrete LEDs gives more flexibility, but gets you further away from a point source (although a true point source is indeed not possible today with LEDs at any considerable power levels), and comes with a few manufacturing challenges which might have been deal-breakers 10 years ago, but that are manageable in the DIY realm today.

Flat black paint, the type for flocking telescopes, works well. I'm considering adding a few baffles too. So far I haven't really had any problems with stray light.@douwe and others who built UV enlargers: how do you deal with internal stray light? Black paint? Or?

Do you have any recommendations for what series of lenses I should be looking for? My second question is about how much power I should want for the light source..

I have come to the following conclusions on lenses:

1. multicoating doesn't pass UV very well, older coatings, and coatings for older enlarging lenses are preferable.

2. Thin glass passes more UV light than thick glass (obviously).

3. Cemented groups may block some UV light as well.

So, an older lens with thin glass elements that is not multicoated seems best. I use a kodak enlarging ektar 100/4.5 that is likely made with lanthanum glass. I think this lens is good because the dialyte design (4 lenses in 4 groups) has no cemented groups, the glass is thin on account of the design and the use of higher refraction lanthanum glass. I recommend you try a dialyte type lens, there are probably dialyte lenses that cover 8x10 because it was a popular design back in the days.

As to power: Its the print size that counts, as mentioned by Fraunhofer. My condensor enlarger with 40W 380nm LED makes a 50x65cm cyanotype print in 20-45 minutes depending on film base type and chemistry used. This would not change fundamentally for 8x10, but your condensor system would be a lot larger. (I think you can find large fresnel lenses without any problems)

One last point on wavelengths: I use a 380nm LED. In my experience cyanotype isn't very sensitive to 395nm, so this wavelength lengthens exposure significantly. On the other hand enlarger lenses and glass in general don't pass 365nm very well, at least much less so that 395nm. I found that 380nm can still pass through glass and excite the cyanotype chemistry, it might the best wavelength for this application. I'd be curious to learn about your experiences.

Ethan Brossard

Member

I have come to the following conclusions on lenses:

1. multicoating doesn't pass UV very well, older coatings, and coatings for older enlarging lenses are preferable.

2. Thin glass passes more UV light than thick glass (obviously).

3. Cemented groups may block some UV light as well.

So, an older lens with thin glass elements that is not multicoated seems best. I use a kodak enlarging ektar 100/4.5 that is likely made with lanthanum glass. I think this lens is good because the dialyte design (4 lenses in 4 groups) has no cemented groups, the glass is thin on account of the design and the use of higher refraction lanthanum glass. I recommend you try a dialyte type lens, there are probably dialyte lenses that cover 8x10 because it was a popular design back in the days.

As to power: Its the print size that counts, as mentioned by Fraunhofer. My condensor enlarger with 40W 380nm LED makes a 50x65cm cyanotype print in 20-45 minutes depending on film base type and chemistry used. This would not change fundamentally for 8x10, but your condensor system would be a lot larger. (I think you can find large fresnel lenses without any problems)

Looks like the Kodak Enlarging Ektanon 10" f/4.5 will be exactly what I need, thanks!

380nm LEDs aren't nearly as expensive as the 365, and only a bit more than the 395, so I'll add that one to my parts list, thanks for that too!

Where did you source your fresnel lenses from? I found ones that would work at edmunds, but I'm wondering if there might be cheaper sources elsewhere.

Alibaba

Not sure where you read this and whether it's true or not. Frankly I'd expect that in principle the shorter the wavelength, the higher the printing speed as shorter wavelength light simply carries more energy. However, there's a tradeoff in the sense that UV blocking by all materials in the optical path (ultimately also the atmosphere if you get to low enough wavelengths) becomes and issue. I have the impression that the 365 wavelength peak sensitivity of alt. processes is not necessarily very well substantiated in terms of physics and that it's a combination of testing methods, definitions and practical availability of materials/light sources that has led to this understanding.

One of the best resources out there, at least with easy availability, is the well-known UnblinkingEye page written by Sandy King on the subject: https://unblinkingeye.com/Articles/Light/L2/l2.html (note that there's also a page 1 of the article, but I linked directly to the 'dirty pictures').

While it's one of the few (and perhaps the only one) true comparisons of several light sources and processes, and therefore of great value, methodologically it's not bullet-proof. Likely it was never intended to be, and instead was intended (and succeeded!) in giving practical recommendations based on empirical evidence to printers. Since the article was published before UV leds became commonly available, it doesn't say anything about them. Indeed it would be interesting to revisit the topic with these new light sources at hand, which would be particularly interesting due to their inherently narrow emission peak compared to UV tubes, let alone HMI's.

Long story short, if you ask where the optimal sensitivity of your alt. process is, I would say "the shortest wavelength that does not suffer from severe attenuation". That likely happens to be in the 350 ~ 375nm range. This will give you 'the most exposure' per Watt of electrical power you throw at it.

If you ask, what gives me the most exposure per dollar value, then it's a different story and you'll end up right at the 395nm spot where entry-level UV leds are the cheapest. Note that this is a rather sensible question to ask given the price differential between 365nm and ~400 nm leds. If a 365nm led costs 5x as much as a similarly powered 400nm one, but only gives one stop of speed advantage (if that!), it'd still make sense to go for the slower but cheaper 400nm ones (and invest some cash in better cooling).

Perhaps that was a slip of the pen, but New Cyanotype is actually a few stops faster than salt. The difference is something like 2~3 stops. So if you need a 20 minute exposure for New Cyanotype, count on a 80 ~160 minute exposure for salted paper.

Yes, I meant to say 4 x 8 times more sensitive than SALT - Alan

Yes, that could work. But note that you'd need to use a metal-core PCB for this. No plain old FR4, as it won't allow for sufficiently easy heat dissipation. It seems that e.g. JLCPCB offers an affordable aluminium option these days. The odds that the appropriate high-power UV leds are in their catalog are pretty slim, so you'd have to solder them onto the PCB yourself. Note that this will require some kind of reflow setup; the cheapest of which is one of those hot plates that are in vogue these days (and work surprisingly well). I did this for my RGB LED enlarger head (360W on 10x15cm PCB, so a little over 2W/cm2).

By far the easiest approach is to take a COB led or even a ready-made product based on a COB led and take care of the cooling/heat dissipation problem. Discrete LEDs gives more flexibility, but gets you further away from a point source (although a true point source is indeed not possible today with LEDs at any considerable power levels), and comes with a few manufacturing challenges which might have been deal-breakers 10 years ago, but that are manageable in the DIY realm today.

| Photrio.com contains affiliate links to products. We may receive a commission for purchases made through these links. To read our full affiliate disclosure statement please click Here. |

PHOTRIO PARTNERS EQUALLY FUNDING OUR COMMUNITY:  |