Y'know, I'm really starting to think photography was a miracle in the first place....

Not just one. If you think about it, it's a whole slew of miracles knitted together into a magical blanket.

"Back"? But the rehalogenating bleach brings those halogens with it, right?

Yes, by "back" I meant that the silver once was a silver halide, then metallic silver, and then it's turned 'back' into a silver halide. But the original halide is gone and replaced with a new halide from the bleach.

do emulsions need to be cut (as in the traditional noodle + wash steps)

No. There's a funny moment when we were walking through the Fuji factory that makes color paper and one of our group members asked "so where do you do the noodling?" The engineer who toured us looked puzzled (I guess he thought for a moment she was making an inappropriate remark about things the factory workers may do during overtime, LOL!) In reality, they don't do any noodling & washing in commercial film & paper making, at least not on the Fuji/Kodak (and I assume Harman) scale. Instead, the quantities of the different chemicals are accurately determined and controlled. In home-style emulsion making, you can 'noodle' and wash an emulsion to get rid of the excess halides, but if you don't add this excess in the first place and ensure that all silver (nitrate) and bromides/chlorides/iodides find each other, there's nothing that needs to be washed out.

or is that merely increasing surface area and it would work in other ways?

Silver halide crystal surface area and geometry are mostly controlled by the ripening process and parameters such as time, agitation/stirring and temperature. It's a bit like making chocolate, where you also need a fairly well-controlled process to ensure that the chocolate has a nice consistency and doesn't become chunky/granular.

But won't that get washed out immediately upon development?

Everything in a photographic emulsion is intended to stay put, and due to the solubility of the materials chosen, they in fact do. The silver halides are all virtually insoluble in water. The dye couplers are in fact oily substances that are present in the form of tiny little globules interspersed with the gelatin strands. The gelatin itself is almost a magical substance in the sense that it can repeatedly soak up water and dry again, it's a mesh structure that becomes more open (allowing chemicals to travel through it) when swollen, it quit selectively traps the oily dye globules while allowing developer to pass through, it's resilient to both low and high pH without altering its structure too much, and of course it can be first melted (actually dissolved) at a reasonable temperature and after chemical hardening, it won't melt anymore, which is very convenient in the manufacturing process. Gelatin is such an underrated material!

Bleach is a bit of a confusing name

Yes, I agree. "Silver oxidizer" would be more appropriate.

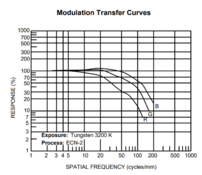

are you not personally concerned with doing any experiments with motion picture negative but developing in C41? Or do you have ECN2 chemicals?

I've processed ECN2 Vision3 film in both C41 developer and ECN2 developer. I find the colors are best for me, personally (i.e. more accurate/true to life) in ECN2 developer. ECN2 developer is very easy to make at home and requires only a handful of chemicals, all of which these days are easy to obtain in most parts of the world. The only 'outlandish' one is CD3, which can be had off of eBay and several other channels in reasonable home-user quantities.

Thank you again for your patience with all my questions!

You're very welcome! I hope I'm able to answer them satisfactorily and that someone(s) may chime in where I drop the ball!