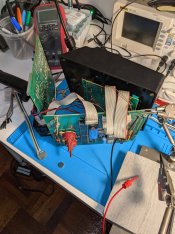

Regarding your testing of swapping out the CPU board and the processor working after that you have pretty much zeroed in on an issue. The ICs are all programed and are unique to each generation of processor. Yes they are generic but still need to be programed.

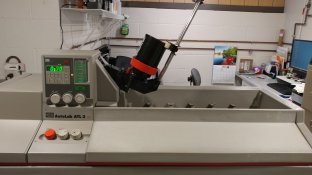

As I watched the video.. it was looking to me like you could have had a power supply issue. The rotation motor is rated for 24 volts and with the motor running at the high speed like I saw in the video I would have suspected a voltage failure in the supply. Their are two relays that control the speed and direction of the rotation motor. Relays #3 & 4 and I have had to replace relay 4 on a power supply board to clear up a rotation issue.

I very recently needed to replace the SET/RUN switch on an ATL-2 Plus recently with errant programming issues and those issues cleared with the replaced switch. Just a thought.

Regarding your replacing of the CMOS battery. That battery's function is to retain the programs that you place into the program channels. I presume you installed a new 3.6v 1/2AA Lithium battery and installed it correctly. Not trying to be sassy but gotta ask the question.

Does your ATL-3 have the automatic filling feature? You can disengage it by placing the #5 dip switch in the down position thus turning that feature off while trouble shooting.

Do you have a service manual for this style processor? The ATL-2 manual is basically the same for information.

How about keeping the head as a parts unit? Most parts will fit your working processors and keeping them going is key also. just a thought.

.