calebarchie

Member

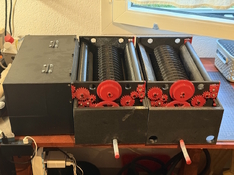

Thanks. That's exactly what I have ordered to make all the assembly RA4 resitant, but I use it inverted. The tubing is stainless steel and the rods POM or PETG. I want to avoid to cut, file and/or mill steel, as you need dedicated and clean cutting blades. The 316 steel tubes come pre cutted. If you cut 316 steel with contaminated (if used to cut carbon or machine steel) blades it can set rust in RA4 environement.

I'm not quite sure I follow or something may be getting lost in translation. You are inserting plastic rods inside a stainless tube (as axels)? While I kind of understand the logic, there is plenty of SS316 in various dias and lengths including pre-cut (usually 300mm) same for silicone tubing if you are needing to retain a 20mm dia. I'm just not sure how well the thin heatshrinking will hold up in use over time.

I suppose just use what you can and have available on your side of the world and keep us updated!