Niglyn

Member

Hi everyone,

I'm currently working on an ESP32 shutter tester. Despite the fact that the main computer is working perfectly, I am having serious issues with the light meter and the optical shutter tester (LED matrix) (MAX7219CWG 2530+). The matrix has shown signs of a bad connection, as it hasn't worked properly (sometimes random LEDs were flashing). I only managed to turn it on properly once. I decided to fix the connections on the matrix board and resolder the connections with the DIN connector, but suddenly the matrix started turning off the whole system (it needs resetting, and then everything works smoothly). The case with the light meter module is different because the ESP can't read it. Even during the system's boot process, it says that the BH1750 is not connected. Everything has been checked with an electronic multimeter, and there are no short circuits, and both the matrix and the light meter connections are good.

https://drive.google.com/drive/folders/1JYlTyYjR-IeasL_swDsMy5MfkJgbeMOl?usp=drive_link (photos of shutter tester)

Hi,

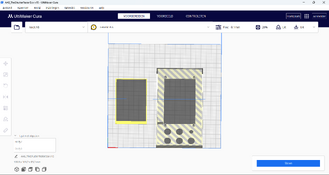

First photo, that soldering looks really rough.

Second photo, I like your box. There is a 3d print file for a bezel to fit the tft, on github.

Third photo, same as the first.

Are you using this horrible lead-free solder? If so, put it in the bin.

Buy proper 60/40 lead/tin solder.

You will have to get that solder off the connectors with a a sucker or wick & try again.