relistan

Member

Hey folks, I am a fan of two bath developers and have in the past used several versions of divided D-76, Barry Thornton's two bath developer, Diafine, etc. I have been working for the last few weeks on concocting a two bath developer to see if I can get something that is usable as a regular developer. Ideally I could use it like Diafine, where I just keep putting back the A and B into their respective stocks until it's time to throw it out. I want to retain full film speed. Diafine and divided D-76 negatives are a bit flat and I'd like a bit stronger contrast if I can manage it. I know everything is compromises.

I found and read 1980s era MSDS sheets for Diafine and read everything I could find about two bath developers (which are almost all MQ—except Diafine). The general theory is that for a two bath developer, substantially no development happens in the first bath and then development starts in the second. I know from experience with various 2 baths that that's just not reality. If you want full film speed, you always have and and need to have a little development in the first bath. The emulsion (at least modern emulsion) just doesn't soak up enough developer to develop only from what was absorbed. So, I decided to try a PQ developer, knowing that phenidone will start development even in mildly acidic solutions.

My thinking was that if I can keep the pH around 8 in bath A, then the phenidone can do some development there and the hydroquinone will really kick in when it hits a highly alkaline bath B. I needed to get the ratio of phenidone to hydroquinone right and wanted somewhat more activity given the split nature of the developer, so I modeled that ratio on ID-67 which would be diluted 1 + 2 for films, but I'm not diluting it. I was trying to keep sulfite to reasonable levels. I want enough to preserve the developing agents, and to act as a mild solvent without getting into a highly solvent scenario. Does the amount I used seem to straddle that? I split the sulfite into both baths to make sure that there is some solvent action for both parts of the development, and to make sure there is a bit of preservative in B.

I'm looking for some advice about things that I might need to think about that I haven't. I've got a developer that seems to work well, has lasted a couple of weeks in partially filled bottles, and retains full film speed. I've put a few rolls through it. It is not buffered at all in the A bath (unless... will sulfite and citric acid form an effective buffer?) and I wonder if that is likely to be an issue, for example.

Here's what I've got. I'll call it experiment 2B-1:

Bath A (1 liter)

So far I have tested it and arrived at the same times for Ilford FP4 and Fomapan 400 (5 mins A, 4 mins B). I know someone will ask about densities and H&D curves but I don't have a densitometer (yet...).

Looking for more general things like "you may need to think about X for longer shelf life" or "substitute X for Y and you'll get improved Z". I was specifically wondering about a developer you keep reusing but without a strong buffer. Reading data sheets, original Diafine seems to use a TSP/citric acid buffer a lot like organic chemists' https://en.wikipedia.org/wiki/McIlvaine_buffer . It also uses TSP mixed with carbonate as the accelerator in the second bath. I have some TSP. I was hoping to keep using citric acid but could switch to sodium metabisulfite.

I was thinking about tap water quality and tempted to add a tiny amount of EDTA (I have a ton of it). But Haist says that EDTA in the developer can actually accelerate oxidation of the developing agent if any iron ions are present.

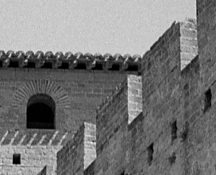

I know it doesn't tell you that much without the negatives (some are drying, will photograph) but it does work well. Here's Fomapan 400 at EI200 (what I normally would use it at in XTOL)

I found and read 1980s era MSDS sheets for Diafine and read everything I could find about two bath developers (which are almost all MQ—except Diafine). The general theory is that for a two bath developer, substantially no development happens in the first bath and then development starts in the second. I know from experience with various 2 baths that that's just not reality. If you want full film speed, you always have and and need to have a little development in the first bath. The emulsion (at least modern emulsion) just doesn't soak up enough developer to develop only from what was absorbed. So, I decided to try a PQ developer, knowing that phenidone will start development even in mildly acidic solutions.

My thinking was that if I can keep the pH around 8 in bath A, then the phenidone can do some development there and the hydroquinone will really kick in when it hits a highly alkaline bath B. I needed to get the ratio of phenidone to hydroquinone right and wanted somewhat more activity given the split nature of the developer, so I modeled that ratio on ID-67 which would be diluted 1 + 2 for films, but I'm not diluting it. I was trying to keep sulfite to reasonable levels. I want enough to preserve the developing agents, and to act as a mild solvent without getting into a highly solvent scenario. Does the amount I used seem to straddle that? I split the sulfite into both baths to make sure that there is some solvent action for both parts of the development, and to make sure there is a bit of preservative in B.

I'm looking for some advice about things that I might need to think about that I haven't. I've got a developer that seems to work well, has lasted a couple of weeks in partially filled bottles, and retains full film speed. I've put a few rolls through it. It is not buffered at all in the A bath (unless... will sulfite and citric acid form an effective buffer?) and I wonder if that is likely to be an issue, for example.

Here's what I've got. I'll call it experiment 2B-1:

Bath A (1 liter)

- Water to 800ml @ 40C

- Sodium sulfite andhyrdous — 35g

- Hydroquinone — 8g

- Phenidone — 0.25g

- Potassium bromide — 1g

- Citric acid — 0.5g (to pH about 8 tested with paper strips)

- Water to 1L

- Water to 800ml @ 40C

- Sodium sulfite anhydrous — 35g

- Sodium carbonate anhydrous — 20g (46g decahydrate crystals if I did math properly)

- pH is about 12

- Water to 1L

So far I have tested it and arrived at the same times for Ilford FP4 and Fomapan 400 (5 mins A, 4 mins B). I know someone will ask about densities and H&D curves but I don't have a densitometer (yet...).

Looking for more general things like "you may need to think about X for longer shelf life" or "substitute X for Y and you'll get improved Z". I was specifically wondering about a developer you keep reusing but without a strong buffer. Reading data sheets, original Diafine seems to use a TSP/citric acid buffer a lot like organic chemists' https://en.wikipedia.org/wiki/McIlvaine_buffer . It also uses TSP mixed with carbonate as the accelerator in the second bath. I have some TSP. I was hoping to keep using citric acid but could switch to sodium metabisulfite.

I was thinking about tap water quality and tempted to add a tiny amount of EDTA (I have a ton of it). But Haist says that EDTA in the developer can actually accelerate oxidation of the developing agent if any iron ions are present.

I know it doesn't tell you that much without the negatives (some are drying, will photograph) but it does work well. Here's Fomapan 400 at EI200 (what I normally would use it at in XTOL)

Last edited: