Friends,

I just read through Angel Albarran's PDF describing the new HP approach to digital negatives. Here is how I see it:

In the HP method negative contrast is set by adding more or less black to a specific green color. This is a fine method, kind of a combination of choosing a specific color with the correct contrast (PDN and RNP array) or setting maximum ink limits (in either the Epson driver or QTR).

The HP digital negative module alters the ink settings so that a gradient of ink tones, from 0 to 100% ink, will linearly transmit UV light over the entire gradient. This would appear to be a useful innovation. The claim in the PDF (which appears reasonable to me) is that linearizing UV transmission will reduce the severity of any subsequent correction that might be applied. HOWEVER, few photo emulsions I know of respond linearly to UV light. So, a correction curve will almost always be needed (as acknowledged in the PDF).

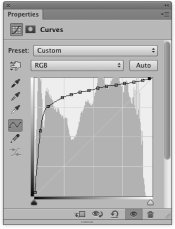

The necessary correction curve is still applied to the image file. But, since it will hopefully be more mild it should also be less destructive.

One of the good parts is that the HP method takes advantage of the built-in spectrophotometer to measure a test print and construct the correction curve.

The really good news, to my mind, is at the end of the PDF. A method is detailed to use the built-in spectrophotometer to profile the entire tri-color gum printing process and make the needed ICC profiles. In principle you would then be able to color correct tri-color gum printing and get the exact color you originally aimed for. This could be a great boon for gum printers striving for predictable color output.

BUT, as nice as the HP method seems to be, I will still stick to QTR.

HP has decided that green with some black is the best color for even smooth tonality. Maybe so, maybe no. It is not my choice and in the HP method you have no control over the color.

And, I still prefer to put all the corrections on the ink settings and not on the image file.

Bottom line, it is really great that a big company like HP would pay attention to the needs of our rather niche market (unlike some big companies we could name). The the HP solution is really pretty good. Like they say, it is a contender.

Ron Reeder

I just read through Angel Albarran's PDF describing the new HP approach to digital negatives. Here is how I see it:

In the HP method negative contrast is set by adding more or less black to a specific green color. This is a fine method, kind of a combination of choosing a specific color with the correct contrast (PDN and RNP array) or setting maximum ink limits (in either the Epson driver or QTR).

The HP digital negative module alters the ink settings so that a gradient of ink tones, from 0 to 100% ink, will linearly transmit UV light over the entire gradient. This would appear to be a useful innovation. The claim in the PDF (which appears reasonable to me) is that linearizing UV transmission will reduce the severity of any subsequent correction that might be applied. HOWEVER, few photo emulsions I know of respond linearly to UV light. So, a correction curve will almost always be needed (as acknowledged in the PDF).

The necessary correction curve is still applied to the image file. But, since it will hopefully be more mild it should also be less destructive.

One of the good parts is that the HP method takes advantage of the built-in spectrophotometer to measure a test print and construct the correction curve.

The really good news, to my mind, is at the end of the PDF. A method is detailed to use the built-in spectrophotometer to profile the entire tri-color gum printing process and make the needed ICC profiles. In principle you would then be able to color correct tri-color gum printing and get the exact color you originally aimed for. This could be a great boon for gum printers striving for predictable color output.

BUT, as nice as the HP method seems to be, I will still stick to QTR.

HP has decided that green with some black is the best color for even smooth tonality. Maybe so, maybe no. It is not my choice and in the HP method you have no control over the color.

And, I still prefer to put all the corrections on the ink settings and not on the image file.

Bottom line, it is really great that a big company like HP would pay attention to the needs of our rather niche market (unlike some big companies we could name). The the HP solution is really pretty good. Like they say, it is a contender.

Ron Reeder