Hi guys,

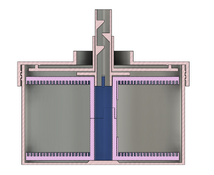

I plan to 3D print a super 8 developing tank to process tri-x reversal at home, and I need some advice on which material to use. My choice is https://www.printables.com/model/1414937-super-8-8mm-16mm-film-development-tank-and-spiral

I have black PLA and PETG-HF on hand. Black, white and transparent (PETG) . Currently I plan to print the reel with clear petg so it would allow easier fogging during reversal. But not sure should I use PLA or PETG for the tank and center core, I know ABS would be better option but my printer can't print it. Anyone have ideas on which one to choose?

Thanks for your reply in advance

I plan to 3D print a super 8 developing tank to process tri-x reversal at home, and I need some advice on which material to use. My choice is https://www.printables.com/model/1414937-super-8-8mm-16mm-film-development-tank-and-spiral

I have black PLA and PETG-HF on hand. Black, white and transparent (PETG) . Currently I plan to print the reel with clear petg so it would allow easier fogging during reversal. But not sure should I use PLA or PETG for the tank and center core, I know ABS would be better option but my printer can't print it. Anyone have ideas on which one to choose?

Thanks for your reply in advance