Blame

@koraks

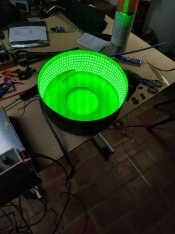

. He pointed out that my LEDs should be driven at higher power in order to expose enlargements on slow papers in under a minute. Papers are most sensitive to blue, so red and green needed boosting. So I bought some Cree XE-G LEDs and installed them

on my original lamp described in this posting, and updated my controller to double the power of red and green, changing from 0.7 amp to 1.4 amps. It works well, but the heatsink, which was a large piece of 1/16-inch thick sheet-metal, got hotter than I like. So I bought an aluminum plate that's six times as thick (3/8 inch), drilled and tapped holes, and moved the LEDs to that.

Installed on the enlarger:

Now the middle gets only slightly warm after running all LEDs at full power for 5 minutes.

This heatsink is overkill (too large). When all LEDs are at max, they consume 51 watts, producing perhaps 30 watts of heat. But I only had choices of 1-foot wide or 2-feet wide when selecting a plate from McMaster-Carr, so I choose 2 feet and cut it down to 20 inches wide. I could have cut it down more, but the weight is the same as the condenser assembly, so the weight is what the enlarger was designed for.

The LEDs emit ample light. This lamp can illuminate a 4x5 negative, and a 35mm frame uses only a small amount of that light (wasting the rest). Yet exposing a 35mm negative onto an 8x10, at f/8, takes only 11 seconds for FOMA RC paper. Ilford RC is only 7.5 seconds. Medium format will be much faster because the larger negative passes more light.

If you have a Beseler 45 enlarger, I encourage you to switch to LEDs. As you can see, it's easy to do with this type of enlarger. All you need to do is remove the lamphouse at the top, remove the condenser, put a circular diffuser at the bottom, put the LEDs on an aluminum plate, and attach the plate to the metal barrel that contained the condenser. That's the easy part. The hard part for most people will be building a controller (driver) for the LEDs. You'll see a couple of designs earlier in this thread.

For the record, here are the LEDs I'm using:

"Photo red", Cree XE-G, 660 nm, drops 2.6 v at 1.4 amp.

"Green", Cree XE-G, 525 nm, drops 3.17 v at 1.4 amp.

"Royal blue", Cree XT-E, 455 nm, drops 3.05 v at 0.7 amp.

Royal blue is available in the new XE-G series, and I'd recommend that instead of the old XTE series.

. He pointed out that my LEDs should be driven at higher power in order to expose enlargements on slow papers in under a minute. Papers are most sensitive to blue, so red and green needed boosting. So I bought some Cree XE-G LEDs and installed them

. He pointed out that my LEDs should be driven at higher power in order to expose enlargements on slow papers in under a minute. Papers are most sensitive to blue, so red and green needed boosting. So I bought some Cree XE-G LEDs and installed them