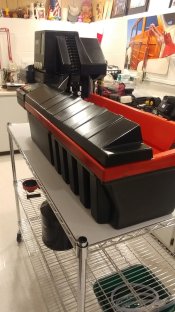

I am in the process of rebuilding a Jobo ATL-2 that I stubbornly purchased from someone who should NEVER be allowed to own any photo lab related equipment. This rebuild is truly a project but my intentions are to hopefully persevere.

I owned several ATL-2s through the years and I have a soft sport for them in the lab. I only wish Jobo was still producing these Auto Labs as new and parts would not be a monumental search or a price gouge when the part is found. I have had some luck with finding parts though and my background helps with the tearing down and now the reassembly. I have had to replace several discreet components and repair cut circuit traces but I now have a some life in the unit. Some important tests are ahead before I run a test roll of film.

I am always on the hunt for any ATL-2 machines and components that may still be out there.

Fred.

I owned several ATL-2s through the years and I have a soft sport for them in the lab. I only wish Jobo was still producing these Auto Labs as new and parts would not be a monumental search or a price gouge when the part is found. I have had some luck with finding parts though and my background helps with the tearing down and now the reassembly. I have had to replace several discreet components and repair cut circuit traces but I now have a some life in the unit. Some important tests are ahead before I run a test roll of film.

I am always on the hunt for any ATL-2 machines and components that may still be out there.

Fred.