BTW, I'm using Phenidone instead of Dimezone. And I've read in a couple of postings that Phenidone is a little more active, implying that less should be used. Is that true in your experience? Are there any image-quality differences between Phenidone and Dimezone?

Technically, there are some small differences in developing properties of Phenidone derivatives. There were many compounds tested, both electrochemically and also photographically, and they were published. The best of the best has been so known, but not really used in commercial formulation because of cost and other practical concerns. There are some small differences between Phenidone A and Dimezone S, but the difference is small enough that you can safely ignore it. (there are folks who linger on tiny points but if you get sidetracked by them you'll never achieve big goals! Learning process has a lot to do with knowing what matters and what don't.) The reason why Dimezone S is preferred is that it is stable in alkaline solution whereas Phenidone A isn't. But at pH of 8.2 and for short term keeping, it's not a problem. If you are making a concentrated developer at pH of 10 and people buy stuff many months after manufacturing, yeah you should use Dimezone S definitely.

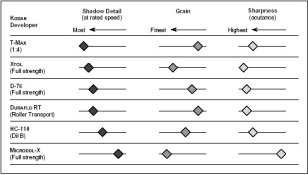

Back on fine grain agents. Be very careful when comparing granularity. A lot of people who think they get better grain with Perceptol or Microdol-X with modern film are in fact underdeveloping. That is, they are ok getting lower contrast with these developers than when testing D-76 or ID-11. What they are missing is that if the film is developed to the same contrast index the grain is same or slightly coarser. One can equally underdevelop in DS-10 and get good results as well.

Halides, ammonia and primary amines are silver halide solvents, but they tend to make bigger grains, at least if you test them in Phenidone-ascorbate type developers.

Sulfite is more gentle fine grain agent, and I prefer 30-80g/L of it in the working solution of fine grain developers. If you can't use sodium sulfite, you can use potassium salt. Also, you can use sulfur dioxide gas reacted with organic base such as triethanolamine. This is what's done in HC-110, but HC-110 also uses primary and secondary amines, which is also silver halide solvent (see above). That's one of the reasons why HC-110 gives coarse grain. (Also the pH is higher.) But such a combination is susceptible to dichroic fog and other forms of silver stain so there are some tricks. Usually, dihydroxybenzophenones, poly(vinyl pyrrolidone), heterocyclic antifoggant compounds, etc., are used in high solvent developers, such as HC-110, Microdol-X, etc. You probably need some quantity of PVP to be effective, but other compounds are used in such a small quantities that they usually don't appear in MSDS. I tried all of the above compounds in DS-10 and its later variants in attempt to increase solvent contents and still get even better image quality. Conclusion: they didn't harm but did not help either, at least in DS-10.

Mine are very common in several cases and are actually in use in some developer, just not in combination or proper combination.

Mine are very common in several cases and are actually in use in some developer, just not in combination or proper combination.