It should last until your clearing test gives you a time that is twice the original clearing time. Supposedly oxidization is a problem if it sits, but I haven't noticed any loss of life from leaving it sitting in a nearly-full jar for very long periods of time. But I am very diligent about clip testing before each batch, which is what I would recommend as well. I also use two bath fixing for films. I process the film for half the decided-upon time in the older batch, and then in the newer batch for the second half (with a one minute rinse in between the two baths).

OTOH, I find that paper fixer goes pretty quickly. In a "serious" long printing session, I usually need to change it at least once. I use 2L of chemicals in each tray when printing.

I use Kodak Flexicolor Fixer for most of my film and paper, and TF-5 with PMK developer and Efke/Adox thick-emulsion films.

OTOH, I find that paper fixer goes pretty quickly. In a "serious" long printing session, I usually need to change it at least once. I use 2L of chemicals in each tray when printing.

I use Kodak Flexicolor Fixer for most of my film and paper, and TF-5 with PMK developer and Efke/Adox thick-emulsion films.

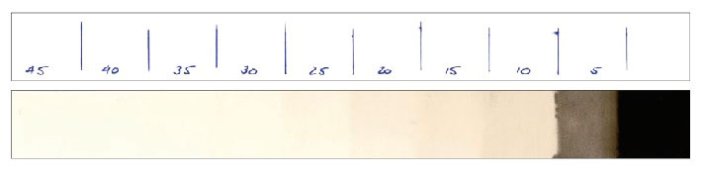

(this is an experiment, to see how long the fixer lasts, the pH after my printing session earlier has risen (i think the buffer was shot) (after i made this post), and the fixing time has now tripled (did so around and after the 15th print, so it is, truely, exhausted. R.I.P! was a sudden failure, i was using fresh stop. i did the usual clearing test before, and after the session (about 20 b/w prints 3.5x5). i refixed the lot with fresh. for now, the fixer has been put into my big container for old fixer to try and recover the silver at a later date. the silver i can see around the container (was a pain to wash from a zoom bottle, i was careful to pour the specks of it back into the big container).

(this is an experiment, to see how long the fixer lasts, the pH after my printing session earlier has risen (i think the buffer was shot) (after i made this post), and the fixing time has now tripled (did so around and after the 15th print, so it is, truely, exhausted. R.I.P! was a sudden failure, i was using fresh stop. i did the usual clearing test before, and after the session (about 20 b/w prints 3.5x5). i refixed the lot with fresh. for now, the fixer has been put into my big container for old fixer to try and recover the silver at a later date. the silver i can see around the container (was a pain to wash from a zoom bottle, i was careful to pour the specks of it back into the big container).