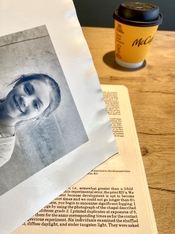

In recent years I am experiencing print frilling using Ilford FB paper. My fix is TF-4 and more recently TF-5. I wash prints with a tray fill and dump method. Heico is my wash aid. My wash wet time is 30-40 min with 5 or 6 dump and fills. I typically am careful to fill the tray with the same tempered 20-22c water. Prints are air dried (20-21c) overnight using green photo plotters. The drying print is left on a counter top face up with a damp blotter under it. The frilled example is affected on one side. I used 2 dry blotters plotting up moisture on each 8x10 print.

In a previous session using the same paper I did not have this problem. I believe our water quality has calcium. However, in past years I have not had these issues so water quality is not suspect. Perhaps it has to do with uneven drying.

Does anyone have any ideas of the cause and a fix?

In a previous session using the same paper I did not have this problem. I believe our water quality has calcium. However, in past years I have not had these issues so water quality is not suspect. Perhaps it has to do with uneven drying.

Does anyone have any ideas of the cause and a fix?

Attachments

Last edited: