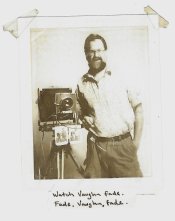

Hello, I just noticed this in a FB print I made about a year and a half ago, which passed the time since then hanged on the wall. I'm supposed to think the yellowish dots started to appear in the top right side of the image, then they spread in other areas. I observed the dots are light reflecting in their first stage, then they become more yellow.

Link to the image: https://iili.io/JWMvBn.jpg

The FB print workflow was the following:

- Dev (factorial development)

- Stop (30 sec.)

- Fixer 1+4 (60 sec.)

- Rinse (5 min.)

- Selenium Toning

- Ilford Washaid (10 min. without agitation)

- Wash (30 min.)

Since then I changed my FB workflow into this:

- Dev (factorial development)

- Stop (30 sec.)

- Fixer 1+4 (60 sec.)

- Wash (30 min.)

- Selenium Toning

- Rinse (5 min.)

- HCA (4 min. constant agitation)

- Wash (30/40 min.)

The rinsing is made with the Paterson RC Washer which basically is a tray with flowing water, the washing is made with a vertical paper washer.

Despite all the recommendations I never used the two bath fixing procedure, but I've always dumped the fixer after 1 square meter of paper processed.

My question is: what went wrong here? The damage has been done by residues of silver thiosulfate or by an improper archival washing? I should mention that other FB prints from the same time, which have been stored in boxes and not hanged to the wall, doesn't have any sign of deterioration.

Link to the image: https://iili.io/JWMvBn.jpg

The FB print workflow was the following:

- Dev (factorial development)

- Stop (30 sec.)

- Fixer 1+4 (60 sec.)

- Rinse (5 min.)

- Selenium Toning

- Ilford Washaid (10 min. without agitation)

- Wash (30 min.)

Since then I changed my FB workflow into this:

- Dev (factorial development)

- Stop (30 sec.)

- Fixer 1+4 (60 sec.)

- Wash (30 min.)

- Selenium Toning

- Rinse (5 min.)

- HCA (4 min. constant agitation)

- Wash (30/40 min.)

The rinsing is made with the Paterson RC Washer which basically is a tray with flowing water, the washing is made with a vertical paper washer.

Despite all the recommendations I never used the two bath fixing procedure, but I've always dumped the fixer after 1 square meter of paper processed.

My question is: what went wrong here? The damage has been done by residues of silver thiosulfate or by an improper archival washing? I should mention that other FB prints from the same time, which have been stored in boxes and not hanged to the wall, doesn't have any sign of deterioration.