- Joined

- Sep 8, 2002

- Messages

- 2,327

- Format

- Multi Format

Durst made one - they called it a "teststrip cassette". I love it. I've bought a few on ebay over the years.Way back when I first started in the darkroom I had a test strip printer that pulled the paper through with a pin. IIRC it was small and plastic and commercial. Might have been made by Paterson, but that was almost 30 years ago so don't quote me on that. I don't know what I ever did with it.

I'm tempted to buy one of these the next time I see one come up for sale on eBay (assuming I remember). Then, perhaps, to 3D model it, and see how easy/hard it would be to make my own.Durst made one - they called it a "teststrip cassette". I love it. I've bought a few on ebay over the years.

The push pin method the Testcassette uses for moving the paper forward is pretty smart. That's the only moving part.I'm tempted to buy one of these the next time I see one come up for sale on eBay (assuming I remember). Then, perhaps, to 3D model it, and see how easy/hard it would be to make my own.

The pushpin mechanism has a spring, so it pops back up when you release pressure on it. It leaves a little prick in the paper. It has no problems with any paper I've used, even heavier stock like Ilford Art 300.

I like your design. It's suitable for color because you can advance the paper solely by feel in complete darkness.Here is video of my device (5x7" paper):

https://streamable.com/5hi7i7

I like your design. It's suitable for color because you can advance the paper solely by feel in complete darkness.

Mark Overton

Winner! Nicely done, so simple. I am going to make one of these.

Winner! Nicely done, so simple. I am going to make one of these.

fantastic!Nice idea! I have Ralph's book and delayed several times making his device. I finally printed this on the Prusa: https://www.thingiverse.com/thing:3145985

Yes, nice!

I'd think I'd make two slight modifications.

1. Make the base slightly longer than the cover (on the paper insertion edge) so you can slide the paper in from the top without having to find the gap.

2. Make the overall width (i.e the notches) be slightly smaller than the paper width so that action is more positive. Having the paper poke out past that notch would make that action more foolproof I think.)

The window is 70x35mm.

The window is 70x35mm.

So I've tested out my 4x5 3 strip prototype and here's the pictures to go with it.

This design combines the advantages of (1) being suitable for color because you can advance the paper in darkness by feel, and (2) wasting no paper because the sawteeth are *under* the flap instead of over it. Clever.Great thread...

Here is my contribution to conversation.

Link to my post showing my design:

https://www.photrio.com/forum/threads/diy-localized-test-strip-printer.115143/

Link to my Flicker page that has an album called "DIY Darkroom Localized Test Strip Printer" that shows the construction of the unit:

https://www.flickr.com/photos/c330shadowcatcher/sets/

View attachment 263769 View attachment 263770

To sum it up, there a basically 2 concepts for testprint devices:

-) moving the paper-strip under a stationary mask (>repetition of same detail at varying exposures)

-) moving a mask over a stationary paper-strip (>varying exposures spread over the image)

This design combines the advantages of (1) being suitable for color because you can advance the paper in darkness by feel, and (2) wasting no paper because the sawteeth are *under* the flap instead of over it. Clever.

The big advantage of having every step in a test-strip cover the same area of your image is that you can place the most important parts of the image there and see how they look with all the exposure-times.

sure

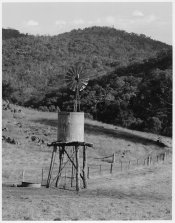

For example, every step above contains the foreground hill, trees and sky. But such a localized test-strip is hard to make because you must move the strip after each exposure and mask everything outside that exposure.

Here's an easy-to-make tool for creating such test-strips.

Start with a hanging file-folder. These are available in office-supply stores and online. Then cut it down like this.

Draw regularly spaced lines as shown above. I taped on a thin strip of white paper with lines so they would be easier to see in safelight. The diagonal sheet of paper is an example of a test-strip consisting of a 4x5 cut in half -- a size I often use when making 4x5 prints.

Hold the device on the easel with hobby magnets as shown above. If your easel lacks a steel surface, make the bottom larger so you can hold it down with weights instead of magnets.

After an exposure, raise the left flap, slide the paper to the right to the next line, and lower the flap.

Ralph Lambrecht, on pages 472-476 of his excellent book, Way Beyond Monochrome (2nd ed) tells us how to make a test-strip printer out of .25-inch-thick plastic sheets that are hinged. My printer above is a simplified version of his device.

I made it large enough to handle a 4x5 test-strip (from an 8x10 cut in quarters). I have found that 4 inches is usually enough to cover the important items in an 8x10.

Mark Overton

| Photrio.com contains affiliate links to products. We may receive a commission for purchases made through these links. To read our full affiliate disclosure statement please click Here. |

PHOTRIO PARTNERS EQUALLY FUNDING OUR COMMUNITY:  |