The brown stuff seems to work great for a long time.

when I saw brown, I assumed it was toast, and down the sink it went.

The brown stuff seems to work great for a long time.

when I saw brown, I assumed it was toast, and down the sink it went.

PQ paper developers have a longer tray life than the equivalent MQ developer, add to that far greater capacity, so they are a far better option. If the OP looks in the resources section I've listed mixing a more concentrated version of ID-62 or ID-78, shelf life is significantly higher.

Ian

@koraks, do the precipitate clouds leave any white powder stuck on the gelatin? Even when viewed in a loupe?

The OP (@BHuij) will appreciate that bit of good news. It means he can forget about adding a sequestrant such as EDTA.

Thanks for catching the typo!! I've corrected my original post.10 g per litre.

Not sure. I've never used E-72 nor compared it to ID-62. I've got all the dry chemicals needed for ID-62 in rather large quantities, but no ascorbic acid, so I'll likely not be making up any E-72 anytime soon.Several people have recommended ID-62 over D-72, primarily those who prefer PQ to MQ formulas - which seems to basically come down to shelf life. However, the E72 recipe I'm using uses Phenidone in place of Metol already, so what advantage does ID-62 have over E-72?

How does ID62 compare to Bromophen, or is it the same chemistry?

How does ID62 compare to Bromophen, or is it the same chemistry?

According to Ilford's website, Bromophen is slightly warm-tone and is PQ-based. So I'd say it's probably close to ID-78. ID-62 is also PQ-based, but is neutral tone.

Mark

My point was the paper emulsion is not softened during dev - or at least not much

Benzotriazole is not added to powder developer due to solubility issues.

Don, do you actually know this, or are you assuming it to be the case because it’s the start of the process? I just wondered how the developer gets in if the emulsion is not softened pretty quickly.

It does indeed.

Also, the OP prefers to use hard well-water, and that requires adding a chelation agent to the developer. EDTA works for ID-62, but not for E-72 as it accelerates the Fenton reaction. Thus E-72 requires distilled/DI water, boosting its cost.

BTW, 4 g/L of disodium EDTA successfully chelates my hard San Diego water, but if yours is much harder and you get precipitation, try 6.8 g/L instead of 4. I calculated the amount needed for the worst-case hardness my Internet search found, and got 1.7 g/L for the working solution, hence 6.8 g/L for the stock solution.

Mark

Hey albada - after trying the E72 I did indeed get a very milky developer. It worked great and the prints came out fine, but I enjoy watching the print come to life in the tray, and clouds of precipitate in the developer made less fun. Worth the cost to add a chelating agent if it means I get clear liquid in the tray. I ordered some EDTA, but upon closer inspection I'm realizing I added tetrasodium EDTA, rather than the disodium you mentioned. Where did you find a calculator to find out how much you would need for your water, and is the tetrasodium going to work the same as disodium? Only thing I can find in googling that sets them apart from each other is that the tetrasodium is alkaline while the disodium is acidic.

Hey albada - [...] Where did you find a calculator to find out how much you would need for your water, and is the tetrasodium going to work the same as disodium?

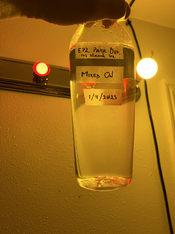

One gram per liter of EDTA did the trick. I put together a quick CAD drawing of a cylindrical container with two compartments so I can keep the alkalai and the non-alkaline ingredients from touching each other while they're waiting to be mixed up. I'm considering the EDTA an alkaline since it's the tetrasodium variant, which I guess has a pH of 11.3. 3D printed a few of these containers, so I now have pre-measured "capsules" of E72 ingredients that should theoretically keep forever. When I'm ready to print, I can dump a capsule into my 1 liter bottle, fill it up to the 750ml line, and shake it for a minute or so with the lid on. Everything goes into solution easy and the developer is totally clear.

Developement seemed a little bit less active compared to my last tests before I added the chelating agent. Not sure why that would be, but I'm still getting full development somewhere between 90 and 120 seconds, so I'm just going to stick with my default 120 seconds.

Did a quick print session tonight where I only made one final print, a 5x7. Felt nice knowing that I didn't have to toss >$1 worth of developer just for that one print, it's nice having the freedom to work on however many or few prints I want in a session without feeling like I'm wasting expensive developer. That said, I poured it from the tray back into the bottle because I might print again tomorrow, and I'd like to see if it passes the 24 hour test. The pre-EDTA version seemed fine after 4 or 5 days on the shelf.

Thanks all for your expertise and help! I'm very pleased with this developer and happy with my results.

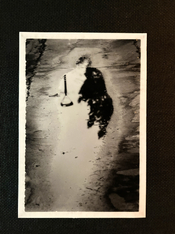

View attachment 326309View attachment 326310

| Photrio.com contains affiliate links to products. We may receive a commission for purchases made through these links. To read our full affiliate disclosure statement please click Here. |

PHOTRIO PARTNERS EQUALLY FUNDING OUR COMMUNITY:  |