Perhaps a second fan (thus an intake and outake) with a HEPA Filter?

First, use a home type HEPA purifier for the room in what you work, see I use a Honeywell HAP16200, but any cheap one with good air flow can be good.

This is a general good advice for handling dry or wet film and of course to scan and enlarge. With that you can dry your film without a cabinet without taking dust, this is an straight solution.

A cabinet can even be better for dust and to speed up drying.

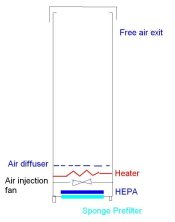

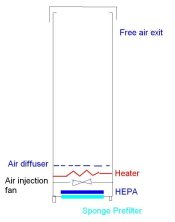

For a DIY cabinet, a bit from my commercially made cabinet design, I'd suggest:

1) Use an HEPA filter in the air injection fan, preceded by an sponge prefilter to protect the HEPA from coarse particles

2) Allow a free air exit in the oposite end.

3) Air diffuser is important, use a plating with holes to spread air flow uniformly. You don't your film move like a flag !!

4) If you use a heater then better to place the intake at the bottom, as heated air tends to ascent.

5) If you are really good at DIY (beware fire/electric risk) you may hack an old home air heater to salvage thermostat, motor/fan and air heater, finding the way to lower the heater power to not rise much ait temperature.

The heating is useful when you have an extremly high air %Humidity, my drying cabinet has heating but I never use it, in normal situations (if not in a hurry) better not using heater of using it with a very mild temp increase, say +8ºC.

This is a regular cabinet with heated air:

The heating element is waterproof or protected from water drops. You may invert the desing placing the heater in the top, for less complications.

Or for even less complications I'd totally avoid the heater, if in a high humidity day you need it then you always may use a home air heater pointing to the air intake area, from a safe distance.