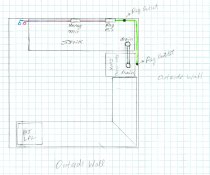

My wet side has two water outlets, muchas others have commented. One is temperature regulated - and one is a basic laundry sink temperature faucet.

The basic faucet I had from a prior laundry room demolition and realignment to create the darkroom space in my basement back in 2004.

The temperature regulated water connection one was once a pair of gate valves, set to the right low flow rate, with a pair of globe shut off valves downstream. It worked ok for a water supply to a roller processor wash section, or a tray syphon when washing in a tray set on top of the roller processor, but only because the cold supply and hot water tank are located close to the darkroom.

As part of the launtry room pressure water revisions I noted that cold water came into my house as a 3/4" line, and then stepped down to 1/2" right after the water meter.

I was moving things already, so I decided to spend about another $100, and fix up the water arrangements better for everything. I ran a new 3/4 cold line all the way from the water meter outlet to the hot water tank inlet.

On the way of getting there, I tapped off 1/2" to the darkroom, 1/2" to the kitchen sink, 1/2" to one outside hose faucet, another 1/2" to another outside hose faucet, 1/2" to the laundry sink and washer connection, 1/2" to the half bath above the darkroom, and finally a 1/2" to the upstairs bathrooms.

Tapping off the 3/4" line, with the main water shut valve set to not constrict flow allows for competing 1/2 taps to draw, with barely any pressure drop on another line that is also drawing. Had I been relocating the plumbing to the second floor I would have continued the 3/4" up ther. It is the only floor where there are noticable pressure drops on the use of a second cold water tap.

All basement cold and hot water pipes have a foam insulation sleeve over them to minimize temperature transfer to the air.

I plumbed a second drain to sevice the roller processor's waste water collection needs. I worked all the revised drains in ABS for all of the darkroom and launrdy drain revisions, and only tapped into the copper main drain once. I vented correctly as much as possible, but the roller processor drain came later. It has been fitted with a vaccuum breaker, which is not compliant per the plumbing codes around here, but seems to work just fine.

Then about 6 months ago I dropped into a photo supply outlet I buy from to gift away a couple of photo copy paper boxes filled with cases of large photoflash bulbs.

I pass all large bulbs I come across to a clerk who works there. This was the second occasion I had done so.

Recently I had bought a large lot of flashbulbs in an auction lot. I don't fire anything larger than AG-3's, and Kat loves bulbs sized #25 and larger.

She was very appreciative of my gift. we were gabbing away when I noticed what looked to be a water panel laying behind the counter. I asked about it. She decided to gift it to me.

She said she had salvaged a number of them from Kodak's facilities in Toronto when they abandon their Mount Dennis faciliites, and was going to sell that unit to an intersted person the next day.

She said she had another surlpus one at home, and would bring it in tomorrow; take this unit now as a thank you for the flash bulbs gift.

Wo-Ho; lucky me! So now I have a Wing Lynch WP-2 electronic water panel.

It keeps temperature at either 68F, 100F, or variable, at flow rates between 1.5 and 18 l/m. It looks to be early to mid 80's in its build style, so I may have to rejuvinate it with new electrolytic capacitirs if it starts to go wonky, but I have fixed up may other things of that vintange in the same way.

It has two variable flow rate outlets, one metered, and one unmetered. The metered one I feed to the wash section of the roller processor. The other I snake along the back of my sink generally to the place where film wash tanks usually get put when I set up a sink line to process a backlog of 4x5 of c-41 or e-6 types.

The variable outlet I have set for 80F. It tempers pyro and glycin developers to a temperature where their developing agents are tolerably active. Otherwise you wait forever at 68 for these developing agents to get doing anything meaningful.

I hope this long winded post gives you food for thought in planning your bedroom to darkroom water considerations.