I wonder if instead of using Thiosulphate in the sensitiser, is it possible to use the well-tested Cuprotype sensitiser to coat the paper and then replace the Thiocyanate bath in the Cuprotype process with a Thiosulphate bath. If this works then it would be a variant of Cuprotype with the advantage of not having to use Thiocyanate.

-

Welcome to Photrio!Registration is fast and free. Join today to unlock search, see fewer ads, and access all forum features.Click here to sign up

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cyano-vanDyke ... finding a use for used B/W fixer - did i find a new process? or is this an existing process variation?

-

A

- Thread starter Jan de Jong

- Start date

Recent Classifieds

-

For Sale Canon RF 600mm f11, RF 100-400 Lenses

- Started by Jon Shiu

-

For Sale Fujifilm MAXIMA Glossy RA-4 Paper; Packs of 16x20 Sheets

- Started by Aidan Sciortino

-

Sold 1924 Carl Zeiss Jena 150mm f4.5 Lens in dial Compur

- Started by Jon Shiu

-

Found Plastic 5x7 film holders (Fidelity, Lisco)

- Started by blee1996

-

Want to Buy WTB: Digital timer for an enlarger

- Started by Terrence Brennan

Forum statistics

about 25 minutes for cyanotypes in this UV box and about 8 minutes for salt prints.

A bit off topic, but that's really odd. You sure it isn't the other way around? I'd expect a ratio of about 1:2 for cyanotype:salt print with cyanotype being the faster process. (Nee cyanotype is even faster). At least that's my experience, but I admit I haven't done classic cyanotypes in a long time.

I wonder if instead of using Thiosulphate in the sensitiser, is it possible to use the well-tested Cuprotype sensitiser to coat the paper and then replace the Thiocyanate bath in the Cuprotype process with a Thiosulphate bath. If this works then it would be a variant of Cuprotype with the advantage of not having to use Thiocyanate.

That's the next logical thing to try. The cuprotype sensitizer is just the FAC and CuSO4. We don't know though what complications can occur with sodium thiosulfate as a developer. Won't know until you try. May be later today.

I kind of like this POP process though. If the sodium thio developer has some other advantages like boosting the Dmax, that would certainly make it preferable.

:Niranjan.

A bit off topic, but that's really odd. You sure it isn't the other way around? I'd expect a ratio of about 1:2 for cyanotype:salt print with cyanotype being the faster process. (Nee cyanotype is even faster). At least that's my experience, but I admit I haven't done classic cyanotypes in a long time.

Yeah I am pretty sure of that. I just started salt back again - kind of benchmarking with with the basic recipe (12% silver with 6% citric acid and 2% NaCl) and I was certainly happy to see the exposure times shortened from where they were for the cyanos I had been tinkering with previously. So why is that? I am using classic chemistry, but I am also using lower FAC to KFerri ratio than the typical (1.85 vs 2.5.) That makes it a little slower for sure. I might also be pushing the exposure a bit to get a better Dmax.

:Niranjan.

Also possible wavelength of the UV makes a difference -- silver halide may react differently from iron salts (ferricyanide and ferric ammonium citrate) with a narrow-band UV emission, vs. the black body spectrum of sunlight.

So the curiosity got the better of me last night and I thought since I have all the ingredients at hand, why not try this myself. And I must say I was quite pleasantly surprised.

Excellent! This was what I was hoping for.

Perhaps the adjusted ratio makes a difference; in any case I'm quite sure I must have remembered my cyanotype times wrong given your recent comparison.

And probably the paper too, may be hugely. That's why perhaps it was not a good idea to generalize like I did in my post. YMMV, as they say....

;Niranjan.

Excellent! This was what I was hoping for.

Yeah, but who is going to do all the other projects of mine...

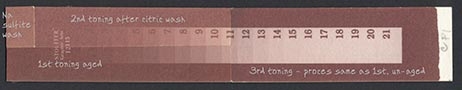

As promised, tried potassium ferricyanide toning on a part of the strip from before - 2% w/v for about 15 minutes (it is kind of slow, but 10 minutes would have been enough.) The piece took a bright crimson(ish) red in the toner bath. There was a significant amount of ferricyanide staining which is difficult to wash off. Needed to soak for about 20 minutes to remove most of it, but still visible on the back side. May be there is some treatment for it.

After drying the color changed to more cooler tone (isn't this how a salt print looks like fresh from exposure?) as can be seen:

Dmax has increased a bit too. Can almost be enough for some images.

So Does this look like the New Cuprotype?

Comments welcome.

:Niranjan

After drying the color changed to more cooler tone (isn't this how a salt print looks like fresh from exposure?) as can be seen:

Dmax has increased a bit too. Can almost be enough for some images.

So Does this look like the New Cuprotype?

Comments welcome.

:Niranjan

Last edited:

-

- Raghu Kuvempunagar

- Deleted

- Reason: double post

Comments welcome.

Nice work Niranjan, now you've to show us a proper print with this method.

tried potassium ferricyanide toning

Are you sure the result does indeed follow the density of the original image? It almost looks like a constant overlay more than density - dependent toning. Contrast seems to have reduced considerably. Do the whites remain clear or are they also fogged purple?

I think one of the essential steps would be to properly mask sensitized areas so you get some pure whites that aren't exposed to see if they clear during processing.

Are you sure the result does indeed follow the density of the original image? It almost looks like a constant overlay more than density - dependent toning. Contrast seems to have reduced considerably. Do the whites remain clear or are they also fogged purple?

Not sure. It does look like the contrast got killed, good observation! I wasn’t paying attention to that yesterday – mesmerized by the color...

Didn’t do the whole strip only the part I showed so don’t know what would have happened to the lighter shades.

Didn’t do the whole strip only the part I showed so don’t know what would have happened to the lighter shades.I think one of the essential steps would be to properly mask sensitized areas so you get some pure whites that aren't exposed to see if they clear during processing.

That was the first thing I did – I am a stickler for the whites, may even a snob. Just exposed one part of a coated strip with 10 minutes and other covered and “developed” and the covered area looked nice and clear – to the eye. In any case the step #21 on the Stouffer is fairly close to a covered area with its density of around 3.0. It and the next 2 or 3 steps are measuring about 242-3 on RGB (desaturated) scale while the bare unprocessed paper measures about 245-6. That is for all practical purposes quite good for any process – particularly one involving FAC.

Having said that, it is not to say that paper has completely cleared. There is almost certainty that FAC didn’t clear out completely (my 7 minutes rinse–develop routine is most likely not adequate.) That would explain a couple of things. If there is a base amount of iron in the paper, it would all turn to Prussian blue on ferryicyanide treatment adding a veil or blue fog to the print, explaining the loss of contrast. Not all did right away perhaps but most did when I put the strip in the oven for heat drying – turning the color to purplish shade (adding blue to the red.)

Also as I mentioned in the earlier post, there is still a good amount of K Ferri left in the paper, adding yellow haze to the strip, further reducing the contrast.

Few things I can try.

1. Cut the other side of the wedge and give it either citric or oxalic treatment ( the latter works better if the Fe is already hydrolysed although if it is in its crytallised form because of the heat drying, it may be already too late) and see if there is improvement of contrast and greater retention of red color on toning and drying.

2. Go back and work on rinse-develop process with longer wash and/or use of citric acid (give it my cyanotype routine.) Use K Ferri as a testing solution on an unexposed area.

3. Find a K Ferri clearing process – what do people do after re-halogenating bleach in the conventional indirect toning process. Sodium sulfite? Or may be just a longer wash.

It is easy to demonstrate the concept – it’s the weeds you get lost….

:Niranjan.

Nice work Niranjan, now you've to show us a proper print with this method.

Thanks, Raghu. Hopefully I will get to it soon, just throw in some old negative that I have from other processes - unless some unforeseen bug derails the process.

:Niranjan.

"The thiosulfate ion is a very versatile chemical, and its reactions in aqueous solution can be used for gas formation, precipitate formation, complex formation, acid-base interaction, redox interaction, catalysis and more. It is not always possible to figure out the exact mechanism in a thiosulfate containing system."

I Grozdanov et al. Experimental study of the copper thiosulfate system with respect to thin-film deposition. Thin Solid Films, 250 (1994) 67-71

I Grozdanov et al. Experimental study of the copper thiosulfate system with respect to thin-film deposition. Thin Solid Films, 250 (1994) 67-71

@Jan de Jong: it is likely that silver plays no role or a very minor role in your experiments and the brown colour you're getting is due to the formation of a sulphide of copper. You may want to wash the print in 2% ammonia and check if the brown colour goes off or becomes dull.

@Jan de Jong: it is likely that silver plays no role or a very minor role in your experiments and the brown colour you're getting is due to the formation of a sulphide of copper. You may want to wash the print in 2% ammonia and check if the brown colour goes off or becomes dull.

In an old depleted/aged fixer, particularly an acidic one, there is a possibility of the presence of sulfur that can form copper sulfide quite easily. But it won't discriminate between Cu(1) and Cu(2).

If it goes dull, is that the indication of presence or absence of copper sulfide?

:Niranjan.

If it goes dull, is that the indication of presence or absence of copper sulfide?

Copper sulphide is soluble in ammonia. So if the brown colour is due to the sulphide then there should be fading.

Few things I can try.

1. Cut the other side of the wedge and give it either citric or oxalic treatment ( the latter works better if the Fe is already hydrolysed although if it is in its crytallised form because of the heat drying, it may be already too late) and see if there is improvement of contrast and greater retention of red color on toning and drying.

Citric acid treatment did "seem" to increase the contrast, but it also bleached the density a bit so can't say for sure unless quantitative measurements.

Even more interesting is the tone of the earlier portion also changed from "purplish" to a more brick or copper red as it aged with a slight boost in visual contrast at the same time. So the earlier judgements may have been premature regarding the color and the contrast.

Finally, toning the rest of the step-wedge (the low exposure side) shows that there is staining in the highlights (step #'s 19-21, not egregious - I have seen worse in cyanotypes and salt, but no cigar either!) It is reddish in color which means that either it is just image product (3.0 density is not enough to block all photo-reaction) or fogging due to "dark" reaction or CuSO4 left over from inadequate washing. If there was any ferrous residue, the color would have tilted towards blue. Again, final judgement after it ages for a couple of days.

3. Find a K Ferri clearing process – what do people do after re-halogenating bleach in the conventional indirect toning process. Sodium sulfite? Or may be just a longer wash.

Na sulfite does clear up the yellow stain of K Ferri but also bleaches badly - so it's not a solution. However, a little bit longer and more diligent water washing seems fine.

Intrigue continues...still academic exercise at this point.

:Niranjan.

Hello Niranjan,3.0 density is not enough

Thank you for the many additions: Yes I think D 3.0 is not enough, as unlike with Cyanotype if first wash is in water, then almost nothing of the faint image is washing off. If first wash is in K Ferri, then a lot is rinsed off as metallic copper and finally the image stays fainter red-copper but darkens slightly. But is light stable, at least keeping it for 1 week in the full sun did not fade it.

I have tried this weekend some combinations of both, and they do not bite so can be applied on the same paper while rinsing with water afterward.

see 2 examples - they are from today so may slightly darken. I am using instead of thio the used-fixer. My experiment with thio - cupper sulfate - FAC was not great. (but that was my fault as i forgot to add the FAC in the solution and only applied over the thio-cu.so4 coating. Exposure looked great but most washed off with water.

example Cyano - Cupro combined 1

example Cyano - Cupro combined 2

- Jan.

You're making really nice stuff with this, Jan, regardless of how the chemistry works. Whatever you do, don't ever get lost in the technical intricacies and always remember what you're doing it all for.

I pour my used fixer, which never is completely exhausted, into a large jar into a large plastic jug, where I toss bits of films a bad prints and allow it to remove the remaing silver material, give a stir from time to time.

When I am ready with a batch of desilvered waste, I decant the fluids, trash the film/paper and allow the water to evaporate off on a larger water jug with a black plastic bag tightly around it, or, in a closed truck/car with just a holed stopper and 1/4" (6mm) plastic hose taking the evaporated liquid out of the closed vehicle through a closed window.

Passive solar heating cost nothing and can be left alone for days, as long as a sheet of plastic tape to the cracked open window.

I'm hoping one day to collect enough sludge to do some of my own fun experimental things with.

Just because others say,"do no bother", there's no reason to heed their counsel and refrain from going your own way.

When I am ready with a batch of desilvered waste, I decant the fluids, trash the film/paper and allow the water to evaporate off on a larger water jug with a black plastic bag tightly around it, or, in a closed truck/car with just a holed stopper and 1/4" (6mm) plastic hose taking the evaporated liquid out of the closed vehicle through a closed window.

Passive solar heating cost nothing and can be left alone for days, as long as a sheet of plastic tape to the cracked open window.

I'm hoping one day to collect enough sludge to do some of my own fun experimental things with.

Just because others say,"do no bother", there's no reason to heed their counsel and refrain from going your own way.

Hello Niranjan,

Thank you for the many additions: Yes I think D 3.0 is not enough, as unlike with Cyanotype if first wash is in water, then almost nothing of the faint image is washing off. If first wash is in K Ferri, then a lot is rinsed off as metallic copper and finally the image stays fainter red-copper but darkens slightly. But is light stable, at least keeping it for 1 week in the full sun did not fade it.

I have tried this weekend some combinations of both, and they do not bite so can be applied on the same paper while rinsing with water afterward.

see 2 examples - they are from today so may slightly darken. I am using instead of thio the used-fixer. My experiment with thio - cupper sulfate - FAC was not great. (but that was my fault as i forgot to add the FAC in the solution and only applied over the thio-cu.so4 coating. Exposure looked great but most washed off with water.

example Cyano - Cupro combined 1

example Cyano - Cupro combined 2

- Jan.

Nice work, Jan....you are doing some really creative things with this concept - I like the blue and gold combo of complementary colors. They go well together. Your cupro image seems to be darker than what I am getting with pure thiosulfate (from what I can gather form the photos.) So it sure looks like there is an additional magic potion in the spent fixer which makes it unique.

Regarding toning with K ferri, I have only done after washing and drying at the first stage. You wouldn't want to put the print directly in the toner right after exposure anyway as it still contains copper in the unexposed areas which will react with the ferricyanide. As in cyanotype, the washing process with or without acidic water is going to play an important role in the final density as well as how much base fog occurs after ferricyanide toning.

Keep it coming......

:Niranjan.

You're making really nice stuff with this, Jan, regardless of how the chemistry works. Whatever you do, don't ever get lost in the technical intricacies and always remember what you're doing it all for.

Thank you Koraks

Trying to add some to the cyano-ish type process and keep the fun of the further creative expression. For that reason for me not too much densitometry although I respect that too. Besides the standard procedures I make always some room for experiments. In this case adding some new ingredients.

Looks like I have something useful, which I hope others can use also in their work.

-Jan.

Thanks, indeed great combination of colors. You can almost invert the colors and keep the same image- I like the blue and gold combo

I am especially taken by the amount of detail that the "brown-golden" process delivers as a sort of logarithmic compression of the tone values. See the picture and compare how on high magnification the grass shows detail in the brown part but almost only 2 tone values in the cyano blue part.

- Jan.

| Photrio.com contains affiliate links to products. We may receive a commission for purchases made through these links. To read our full affiliate disclosure statement please click Here. |

PHOTRIO PARTNERS EQUALLY FUNDING OUR COMMUNITY:  |