originalwinslow

Member

Greetings all, I have recently switched to using Flexicolor developer and am experiencing an issue with elevated base fog/D-Min compared to all the developers I've used previously. I was in contact with Kodak directly and they were unable to give me any good answers besides confirming my liter mix ratios were correct. They thought that the potassium ferricyanide bleach I use instead of the official EDTA could be causing cyan dye problems, but I have been using these chemicals for a year with consistent results and never seen this before. I ran a test strip through CS blix instead of the ferri bleach and saw no improvement. The developer has been pH adjusted to the 10.1 spec, no difference made there either.

I am using LORR developer replenisher without the starter. I am aware that the freshly mixed LORR is more active and can cause fogging in the first few rolls, but the issue has not resolved itself even after bromide seasoning with 20+rolls run through the replenished solution. I ran a back to back dev with CS powder developer and got a normal base D-Min, so it is not related to depleted bleach or fix.

All in all the developer is giving me acceptable results, but in some low-density sections of under-exposed negatives the shadows are quite muddy compared to other developers.

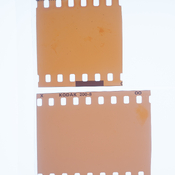

At this point I've run out of things to test. I had assumed that switching to Flexicolor would be an upgrade but that has not necessarily been the case. Here is an image comparing the CS powder developer (top) negatives to the Flexicolor (bottom).

If anyone has any ideas please let me know.

I am using LORR developer replenisher without the starter. I am aware that the freshly mixed LORR is more active and can cause fogging in the first few rolls, but the issue has not resolved itself even after bromide seasoning with 20+rolls run through the replenished solution. I ran a back to back dev with CS powder developer and got a normal base D-Min, so it is not related to depleted bleach or fix.

All in all the developer is giving me acceptable results, but in some low-density sections of under-exposed negatives the shadows are quite muddy compared to other developers.

At this point I've run out of things to test. I had assumed that switching to Flexicolor would be an upgrade but that has not necessarily been the case. Here is an image comparing the CS powder developer (top) negatives to the Flexicolor (bottom).

If anyone has any ideas please let me know.

I was the one who suggested this several times. Perhaps a few others did too.

I was the one who suggested this several times. Perhaps a few others did too.