Hi John, it's been a while since you asked your question, but I'll take a whack at it, as I'm currently experimenting with building my own exposure units based on UV LEDs.

My first exposure unit was a massive 2'X4' fluorescent tube construction that used 10x T12 40-Watt black light bulbs. (I believe they were GE 10526.) I found that, at a distance of about five inches, my standard printing time for full exposure of cyanotypes was around 45 minutes. This was with digital negatives printed on Pictorico OHP, the "original" cyanotype chemistry, and 3/32"-thick glass for my contact printing frame.

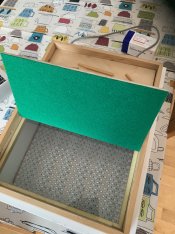

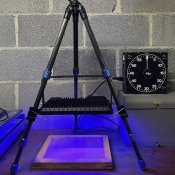

Last year, I moved to NYC and couldn't take my fluorescent monstrosity with me, so I decided to build a much smaller unit based around UV LEDs. Lots of people have used cheap LED strip lighting from Amazon to build exposure units, so I tried the same. A 16ft length of "3528 SMD" blacklight LEDs cost me something like $20. They claimed to emit in the 395nm-405nm range. I made sure to buy a non-waterproof version, which came free of any silicone encasing. (I figured that the silicone encapsulant, though clear, would absorb a lot of the UV light, reducing the effectiveness of the unit. I also thought the encapsulant might yellow or become brittle with age.) I cut the long LED string into shorter strings, soldered wires to them, connected them in parallel, and attached them to an aluminum plate roughly 8"x10". The resulting array was quite dense. I only conducted a few tests with the finished unit, but found that my printing times had reduced to about 20 minutes. I think the key here (compared to my fluorescent unit) is that I was able to bring my prints much closer to the UV source. I designed my wooden box so that my prints were about 1" away from the LED grid. It was not possible to bring my prints this close to the UV source in my fluorescent unit--the light fixtures I used left big gaps between bulbs.

In the end, despite the shorter printing time, I wasn't satisfied with my strip-lighting LED approach. My construction was a bit crude, and my LEDs never seemed to illuminate evenly. (Just by looking at them you could see that they weren't all the same brightness.) So, now I'm working on developing my own tileable LED circuit boards and a driver board to keep them at a constant current (and brightness).

You might have better luck with the strip-lighting. I think it's certainly a valid way to go.