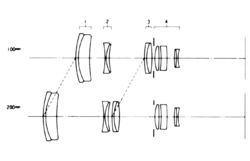

In reassembling the Sigma Zoom K f4.5, 100-200mm Macro, I have met with success. And who originally screwed up the elements? Me, but I was too ‘shy’ to admit such. IC-Racer, I almost had it right, but your diagram finalized things. Again, thanks.

Admittedly, taking apart, then reassembling a zoom lens is not for the faint-hearted. The first time I tried was a disaster. There are two helicoids: one for the focus and one for the change in focal lengths. They are each guided by a (usually) plastic pair of guides on each side of the barrel and sometimes even these guides must be dismantled, but not with the Sigma. I would like to give a few pointers to those who might attempt such. (And offer an invitation to anyone to view my lens and camera graveyard that bespeaks accurately and sadly of my failed attempts.)

First, the main difference between reassembling primes and zooms is that with the prime lenses, as long as the elements are: 1) clean, 2) aligned accurately with spacers where they should be, and 3) facing in the correct direction, all you need to do is tighten the threads and you are done, as they will be collimated correctly.

A tricky part is the thorough cleaning of the elements and assuring that no dust remains upon the glass surfaces. I use glass cleaner or household ammonia (unless lighter fluid is needed to remove sticky residue). I do NOT use alcohol because it does not remove the static charge. NOTE: There are certain ‘rare earth’ elements that cannot withstand any rubbing without leaving telltale scratches. Thankfully, these are far and few between, but one example that comes to mind is an inner rear element on the Minolta 1.4/58 PF which I have learned not to ruin again. Cleaning: I wet with a little glass cleaner the front and back of the element and then hold the element on its sides with my thumb and index finger. With the other hand I insert the fold of a clean, absorbent tissue around the element and gently turn the element until all is dry. This should do 95% of the work. Lingering dust can usually be blown away, but be careful that your lips are very dry or you might get droplets of saliva on the glass and have to start over again. You do not want to rest the element where it can acquire new dust so either put it into an unused, clean plastic food storage bag or insert it immediately into the lens body where it belongs.

Now, with zooms the reassembly is a bit trickier. Zooms, as opposed to varifocal lenses, must retain consistent focus no matter what focal length you change to. This focus parity is achieved by the rear element set maintaining a precise distance from the film plane. In other words, if you screw this element set in COMPLETELY, focus parity will fail. To determine the correct distance you must mount the camera and lens onto a tripod and focus precisely at a bright, detailed object at one extreme of the focal range and then, maintaining the identical position of the focus ring, zoom to the opposite side of the range. Is that image also in precise focus? Probably not, so you must adjust the rear element set inward or outward until focus parity is achieved. Parity achieved, you must lock in this distance. This, on most zooms, is accomplished by tightening an outer ring with threads running in the opposite direction. But on the Sigma there was only a circular bracket that was glued into position. What I did was this: I unscrewed the rear element set casing and wrapped a few rounds of dental floss around its threads. Now, as it is being screwed back in, there is adequate resistance so that when set at the proper distance, all stays that way, but, in the future, readjustment is very easy to do if that should be needed. Also, with zooms, at least with this Sigma, the front element set is also not to be completely screwed into the lens’ barrel. Its precise distance is determined by infinity focus. When the ENGRAVED infinity focus on the focus ring matches ACTUAL focus, the front element set is properly aligned. You then lock that front set in on the Sigma by tightening the three tiny set screws (just below the extended lens hood) so that the front element set can no longer be turned on its threads for adjustment inward or outward.

PHOTOS: The digital photo is of me holding the completed (extended) Sigma. The photos taken with the Sigma (TMX 100 film) are: 1) skyscrapers (hand-held at 1/125), 2) random doors (hand-held at 1/125), 3) macro shot (tripod, but considerably cropped) NOTE: the three black specks on the macro shot (top right of pepper can) are abrasions on the negative. The negatives are VERY sharp. I do not know if these scans (done at a copy shop) are worthy.

My, how intelligent is David Lyga! (But let’s discuss this ‘truism’ a bit further in order to completely review the accuracy of this bold, fulsome statement.)

The lens was purchased for five dollars. When bought, it was pristine and the ONLY flaw was a negligible amount of inner haze that really meant nothing, optically. But that annoyed me. So I began disassembling and trusting my memory to aid me in reassembling after the glass was thoroughly cleaned. Halfway through, I received a phone call that necessitated doing a chore. When I returned I was a bit confused but resumed work. Then the trouble started. I dropped an element onto the linoleum floor (because I did not bother to clear my workspace beforehand; thus, the workspace was too cramped). The element survived, but managed to get a minor scratch. (That seemed to negate the tiny advantage of haze removal). I then spent a whole two days (daze?) trying to reassemble the elements. I then decided that either I would trash the lens or commit myself to an institution if I spent any more time trying to rectify my utter stupidity (or…really more accurately… cupidity!) I then put out a call for the diagram: one to APUG and one to SIGMA. Apug responded; ONLY Apug. (And now, four days later, Sigma still has offered no response. STOP PRESS! SIGMA REPLY 8 July:

Hello David,

We no longer have any service records or diagrams for your lens in hard copy and the lens predates our computer database, unfortunately we cannot assist you.

Yours Truly,

Paul Pizzano

Sigma Corporation of America)

Optically, I had started to ‘get close’ towards the end but the diagram was what finally pushed all the bad omens ‘off the cliff’ and gave me a bit of respite. I then spent another half day cleaning the casing, re-cleaning all the elements, making all the adjustments, and, finally, taking the pictures. This lens is one of the sharpest I have ever tested. But how much did it REALLY cost to acquire? Five dollars? Few are as obsessed with squeezing blood out of a stone.

My, how intelligent is David Lyga! Indeed, perhaps not. - David Lyga

I make my own sometimes because you can no longer find some of the special types watchmakers once used.

I make my own sometimes because you can no longer find some of the special types watchmakers once used.