kwmullet

Member

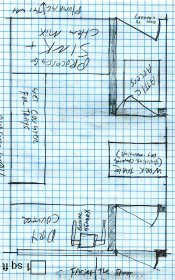

Is anyone in either the north half of Texas or the south half of Oklahoma using a homebrew wood sink in their darkroom? Sometime in the next 4-6 months, I'd like to eyeball one or more such sinks as we move and I begin my garage conversion to a darkroom. As is a common theme in such projects, I'm trying to keep costs down as much as possible, so I'll be looking at the local Habitat for Humanity store for materials, getting some Ready To Assemble cabinets from Home Depot or Lowes, and putting in wiring, outlet boxes and outlets myself so an electrician can install a GFCI circuit and attach it to what I've already installed. If I can learn enough rudimentary plumbing, I'll install the water supply and drainage piping and fixtures myself and hire a plumber to likewise inspect and attach to the existing systems.

I've already gotten a dandy prefab sink from Jeremy Moore that is ideal for film processing & chem mix, but about half the size I would want for my print tray line.

cheers,

-KwM-

I've already gotten a dandy prefab sink from Jeremy Moore that is ideal for film processing & chem mix, but about half the size I would want for my print tray line.

cheers,

-KwM-

) with a nice cherry or walnut stain, and topping it off with five or six coats of polyurethane, so it's got a hard, glossy surface but a nice, deep grain structure and is pleasing to the eye. Then, I could echo the appearance of the sink in a display rail that goes around the entire room similar to the ones used at Lenswork.

) with a nice cherry or walnut stain, and topping it off with five or six coats of polyurethane, so it's got a hard, glossy surface but a nice, deep grain structure and is pleasing to the eye. Then, I could echo the appearance of the sink in a display rail that goes around the entire room similar to the ones used at Lenswork.