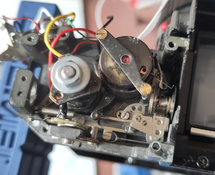

This week-end has been an interesting one. I'm still making my way around this mirror box, and also investigated the general status of the camera.

Since I lost trace of where the different wires were going, I opened my other F1, for a quick comparison. Obviously I found where the wires would go, and understood my mistake: the camera was wired correctly but I did not find the right wire to unsolder. Anyway, since it was strangely routed, I'd had issues to get it out so I think I did the right thing.

So I replaced the white wire by a brand new one.

Comparing the cameras was instructive, as it shows the F1n is not just a cosmetic revamping of the Old one:

For example the "power control" system is very different, reeds are used in the new one instead of flat contacts (which look quite dirty by the way...)

F1n power control.

F1 old power control. Contacts have been cleaned with IPA, there was a lot of CRUD there.

The underside look similar but one can see differences nonetheless, it would be interesting to know why there are made and what they bring.

The F1n is at the top, the cameras are not in the same state, but it's easy to see the rewind button is locked differently for example.

Cameras were not in the same state because... I discovered there are many ways to jam a F1. I struggled the whole afternoon trying to put the mirror box back in place (and realize I'm not sure what worked at the end) . The lever at the top which confirms the mirror is up so that the shutter can be released is accessible using a small probe inserted near the speed control knob. Zydaric's recommendation to half-wind the mechanism is good (this is also how I jammed the camera...)

Even if I know I'll have to remove the mirror box again, I took the opportunity to remove crap from the camera using compressed air. For this, I put the back in place, and shielded the shutter with a piece of business card (yes it's a shameless plug for my company ;-) that's all I had)

Curtains are still dirty, I dont know how I could get them clean. May try a sensor swab or something like this.

To finish in beauty, since the box is back in place, I did not resist putting the prism rails back, and try focusing using the other F1's screen... Looks nice to me, so I guess the question is more

when the camera works again than

if it can work again...

A special note for

@Andreas Thaler : I found some wear in the camera, which tells something about how much it was used I think. It's on the lever that locks the aperture striker (I did not investigate other places at the moment) and is quite obvious...

Edit: a quick check shows the F1n has no visible wear in this place. S/N of the old one is 208345, the "F1n" is 653205.

I'm waiting for a "A" screen that I'll dedicate to this camera, as it was the initially fitted screen, and the "E" one will go back to the other one, for which it was the "normal" screen. And still looking for a prism at a decent price, or a parts camera if any crosses my way...

).

).