tonyjuliano

Member

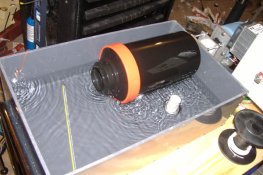

I recently almost lost the use of my JOBO CPE2 film processor.

Luckily, I managed to revive it, but it's not getting any younger.

The fear of living without it has made me resolve to come up with an alternative.

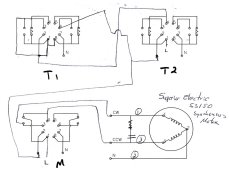

I have the knowledge (I'm a mechanical engineer with a background in manufacturing), the resources (I still have access to high-end design tools, and friends with electrical expertise), the motivation (I live in fear of having to go back to processing by hand), and the time (well maybe the time, we'll see).

Read all about my plan Dead Link Removed (and if you wish to participate, pipe up!)

Luckily, I managed to revive it, but it's not getting any younger.

The fear of living without it has made me resolve to come up with an alternative.

I have the knowledge (I'm a mechanical engineer with a background in manufacturing), the resources (I still have access to high-end design tools, and friends with electrical expertise), the motivation (I live in fear of having to go back to processing by hand), and the time (well maybe the time, we'll see).

Read all about my plan Dead Link Removed (and if you wish to participate, pipe up!)