grainyvision

Subscriber

So I did some searching beforehand on photrio and basically only found questions of "if this possible" and "it was a proprietary process, it won't work"... Well I decided to try it anyway. The Anscochrome I have is probably some of the best kept stuff in the world. I bought a lot of expired film from an estate sale. Tons of different stuff including ansocchrome in a variety of formats. The person who I bought the film from told me he found it in the guy's fridge. Comparing it to the other B/W films, this definitely appears to be the case. So it's all "good" condition but not perfect. It doesn't appear it was all frozen, just kept cold and temperature controlled.

So I did a few preliminary tests on Anscochrome and found that the biggest caution is that the emulsion is extremely soft, especially when wet. Even when dry it can be deformed a bit by pushing on the film pretty hard. I also tested that it responded to C-41 developer by simply putting a strip of the 35mm in room temp C-41 for a few minutes followed by bleach and fix. C-41 will develop color on the film. Total stock is a few rolls of 35mm in 500 ASA, 1 35mm roll of duplicating film, 1 4x5 pack fo printon direct positive paper, 2 4x5 daylight films, 2 (1 opened) tungsten films. All films had an expiration date of between 1963-1967. The preopened tungsten is what I started with. The package doesn't actually have any speed or real directions other than saying that it needs a filter. The specific pack I used said it needed 05M. I ended up doing some research and found of all things a military photography document about the processing instructions and speed of these 4x5 sheet films. The daylight film is 32 ASA (reduced to 8 ASA under tungsten with filter) and the tungsten film is 25 ASA (20 ASA under daylight with filter). The processing time required is... intense. Temperature is to be 68F +/- 0.5F, throughout the entire process. Basic summary:

* First developer - 14m

* Stop

* Harden

* Wash

* Re-expose - 1m per side

* Color developer - 14m

* Harden

* Stop

* Wash

* Bleach - 5m

* Wash

* Fix - 4m

* Wash

* Final Rinse

The process was proprietary and in my searching I've not found any info at all about the process other than that it existed and these processing instructions. I couldn't find what color developing agent it used, potential agents of the first developer... anything. But I have a lot of film that is otherwise useless to me... So, I did a thing.

I shot 2 sheets of the tungsten film as a long-exposure under tungsten lights. One was shot at 25 ISO using a 30s exposure time, the other was with 1/4 of the film shot at ~50 ISO for 15s and the other portion of the film shot at 12 ISO for 60s. I also ignored the filter recommendation

Processing temperature was 70F (room temp) and all washing done with cold water from my tap (~60F). I used a spearman 4x5 developing tank and did agitation every 1 minute. My process was as follows:

* First developer - custom dilution of HC-110, 30ml of concentrate to 700ml of water - 13m

* Wash/water stop

* Re-expose, 1 minute per side (this emulsion strangely seems double sided!?)

* Color developer - Normal Kodak C-41 LORR working solution developer - 15m

* Wash/water stop

* Bleach - Fujihut C-41 bleach - 7m

* Wash

* Fix - Fujihut C-41 fix - 7m

* Wash

Amazingly, the results are proper kinda usable (with correction) color! The emulsion is marred some on the edges and is extremely fragile through every step of the process. Definitely only handle by edges and if you're really worried, don't have any of the important part of the image on the edges when taking a picture. The spearman tank system actually scratched the edges of the film due to how soft the emulsion is.

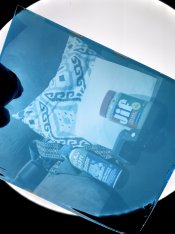

There is a very strong cyan shadow cast, but otherwise a visible representation of all colors. The results were fairly low contrast for slide film, but if I'm only developing this film to scan it, then what does that matter. I believe the cyan cast is primarily due to age fogging. During re-exposure, one side of the film was quite dark with fog and the other side seemed to have little or no fog. There was no eye-visible grain and red and green seems to be rather balanced despite the cyan cast. Because of the low contrast, both exposure levels produced decently usable results. The 50 ISO exposure didn't really cover enough of the subject to tell, but the 12 ISO shot looked to be the best. Whites also appeared to properly go to clear at 12 ISO with maybe a bit of cyan cast. A heavily fogged (I messed up loading the holder) sheet was also developed and came out with a very slight orange cast on the clear film.

Overall, the results are definitely exciting, even if most of the surviving film out there would be insane to process as reversal due to sub-par storage. I don't have a good proper way of scanning LF film so that's the primary reason I went with reversal. This film would likely produce reasonable and easier to correct results in C-41 negative developer, when done at low temperatures.

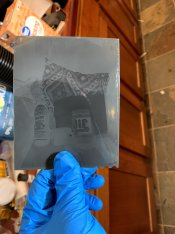

Attached pictures are a simple phone photo of the backside of the film during re-exposure (front side was too dark to really get a good picture of). The other picture is the final 12 ISO image on a daylight backlight

So I did a few preliminary tests on Anscochrome and found that the biggest caution is that the emulsion is extremely soft, especially when wet. Even when dry it can be deformed a bit by pushing on the film pretty hard. I also tested that it responded to C-41 developer by simply putting a strip of the 35mm in room temp C-41 for a few minutes followed by bleach and fix. C-41 will develop color on the film. Total stock is a few rolls of 35mm in 500 ASA, 1 35mm roll of duplicating film, 1 4x5 pack fo printon direct positive paper, 2 4x5 daylight films, 2 (1 opened) tungsten films. All films had an expiration date of between 1963-1967. The preopened tungsten is what I started with. The package doesn't actually have any speed or real directions other than saying that it needs a filter. The specific pack I used said it needed 05M. I ended up doing some research and found of all things a military photography document about the processing instructions and speed of these 4x5 sheet films. The daylight film is 32 ASA (reduced to 8 ASA under tungsten with filter) and the tungsten film is 25 ASA (20 ASA under daylight with filter). The processing time required is... intense. Temperature is to be 68F +/- 0.5F, throughout the entire process. Basic summary:

* First developer - 14m

* Stop

* Harden

* Wash

* Re-expose - 1m per side

* Color developer - 14m

* Harden

* Stop

* Wash

* Bleach - 5m

* Wash

* Fix - 4m

* Wash

* Final Rinse

The process was proprietary and in my searching I've not found any info at all about the process other than that it existed and these processing instructions. I couldn't find what color developing agent it used, potential agents of the first developer... anything. But I have a lot of film that is otherwise useless to me... So, I did a thing.

I shot 2 sheets of the tungsten film as a long-exposure under tungsten lights. One was shot at 25 ISO using a 30s exposure time, the other was with 1/4 of the film shot at ~50 ISO for 15s and the other portion of the film shot at 12 ISO for 60s. I also ignored the filter recommendation

Processing temperature was 70F (room temp) and all washing done with cold water from my tap (~60F). I used a spearman 4x5 developing tank and did agitation every 1 minute. My process was as follows:

* First developer - custom dilution of HC-110, 30ml of concentrate to 700ml of water - 13m

* Wash/water stop

* Re-expose, 1 minute per side (this emulsion strangely seems double sided!?)

* Color developer - Normal Kodak C-41 LORR working solution developer - 15m

* Wash/water stop

* Bleach - Fujihut C-41 bleach - 7m

* Wash

* Fix - Fujihut C-41 fix - 7m

* Wash

Amazingly, the results are proper kinda usable (with correction) color! The emulsion is marred some on the edges and is extremely fragile through every step of the process. Definitely only handle by edges and if you're really worried, don't have any of the important part of the image on the edges when taking a picture. The spearman tank system actually scratched the edges of the film due to how soft the emulsion is.

There is a very strong cyan shadow cast, but otherwise a visible representation of all colors. The results were fairly low contrast for slide film, but if I'm only developing this film to scan it, then what does that matter. I believe the cyan cast is primarily due to age fogging. During re-exposure, one side of the film was quite dark with fog and the other side seemed to have little or no fog. There was no eye-visible grain and red and green seems to be rather balanced despite the cyan cast. Because of the low contrast, both exposure levels produced decently usable results. The 50 ISO exposure didn't really cover enough of the subject to tell, but the 12 ISO shot looked to be the best. Whites also appeared to properly go to clear at 12 ISO with maybe a bit of cyan cast. A heavily fogged (I messed up loading the holder) sheet was also developed and came out with a very slight orange cast on the clear film.

Overall, the results are definitely exciting, even if most of the surviving film out there would be insane to process as reversal due to sub-par storage. I don't have a good proper way of scanning LF film so that's the primary reason I went with reversal. This film would likely produce reasonable and easier to correct results in C-41 negative developer, when done at low temperatures.

Attached pictures are a simple phone photo of the backside of the film during re-exposure (front side was too dark to really get a good picture of). The other picture is the final 12 ISO image on a daylight backlight

Attachments

Last edited:

However Jacobsons show CNS bleach around pH 6 for AGFA and reversal bleach around pH 5.0 and 5.4 for AGFA / ANSCO. 4.8 might be the lowest I would go, but I think Jacobsons (based on BJP) and BJP are often more from practical experience and perhaps Glafkides is closer to the chemistry. My round about way of saying Glafkides might be right-er.

However Jacobsons show CNS bleach around pH 6 for AGFA and reversal bleach around pH 5.0 and 5.4 for AGFA / ANSCO. 4.8 might be the lowest I would go, but I think Jacobsons (based on BJP) and BJP are often more from practical experience and perhaps Glafkides is closer to the chemistry. My round about way of saying Glafkides might be right-er.