Hi all, could use a little help here.

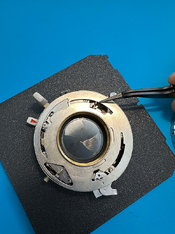

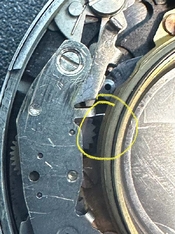

Long story short, got a good deal on a 135 mm Symmar lens attached to a Synchro-Compur shutter (#051-24). Out of the box fast speeds all worked well, but at slow speeds the shutter would stick open and would require gentle to get it to close. I have repaired small things in the past so I decided to give it a go after scouring for repair guides and videos. I opened the shutter, removed the cam ring, cocking ring and got the escapement out, gave it a clean, lubed it up with watch oil and replaced all the parts. So far so good. Once reassembled fast speeds worked as usual, but now the slow speeds all seemed to fire fast too. Upon reinspection it seems like the pallet arm that controls the slower speeds doesn't want to follow the groves in its cam. It has no tension pushing it towards the inside of the shutter housing. When I cock it to a 1s position and place some gentle pressure on the pallet I can get the slow speed mechanism to work. I'm a bit stumped (having taken it apart and put it back together a half dozen times). I've read that some escapements need to have a spring set to a particular diameter to get the pallet to work, but that doesn't seem to be the case here. It also doesn't seem like the coverplate has any protrusions that interact with the pallet arm. I'm a bit at a loss but I feel like I'm so very close to getting the damned thing to work. Any advice would be amazingly appreciated. Some pictures for context:

Long story short, got a good deal on a 135 mm Symmar lens attached to a Synchro-Compur shutter (#051-24). Out of the box fast speeds all worked well, but at slow speeds the shutter would stick open and would require gentle to get it to close. I have repaired small things in the past so I decided to give it a go after scouring for repair guides and videos. I opened the shutter, removed the cam ring, cocking ring and got the escapement out, gave it a clean, lubed it up with watch oil and replaced all the parts. So far so good. Once reassembled fast speeds worked as usual, but now the slow speeds all seemed to fire fast too. Upon reinspection it seems like the pallet arm that controls the slower speeds doesn't want to follow the groves in its cam. It has no tension pushing it towards the inside of the shutter housing. When I cock it to a 1s position and place some gentle pressure on the pallet I can get the slow speed mechanism to work. I'm a bit stumped (having taken it apart and put it back together a half dozen times). I've read that some escapements need to have a spring set to a particular diameter to get the pallet to work, but that doesn't seem to be the case here. It also doesn't seem like the coverplate has any protrusions that interact with the pallet arm. I'm a bit at a loss but I feel like I'm so very close to getting the damned thing to work. Any advice would be amazingly appreciated. Some pictures for context: