My Nikkormat ELW and winder came today. Looks like the little white nylon gear on the motor shaft of the winder is split. Doesn't seem very likely I'm ever going to be able to dig up a replacement. The motor shaft spins nicely inside the gear. This is a situation.

-

Welcome to Photrio!Registration is fast and free. Join today to unlock search, see fewer ads, and access all forum features.Click here to sign up

- Home

- Forums

- Analog Workflow Forums (100% Analog/Traditional)

- Analog Equipment

- Camera Building, Repairs & Modification

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Split Nikkormat AW-1 motor shaft gear

-

A

- Thread starter sissysphoto

- Start date

Recent Classifieds

-

For Sale Will Travel 4x10 camera Fujinon SW120mm f8 lens in Copal

- Started by Simon Benton

-

For Sale Sinar Norma / S2 8x10 camera

- Started by Guivd

-

For Sale Mint Nikon D2X Camera Body

- Started by Barlow

-

For Sale Rollei 40mm Sonnar F2.8 LTM

- Started by RoboRepublic

-

For Sale Schneider Kreuznach Super Symmar HM 210mm

- Started by Guivd

Forum statistics

- Joined

- Dec 27, 2013

- Messages

- 1,360

- Format

- Medium Format

A well-tooled machinist can replicate your gear.

Oh. Well thanks. I can see that being a couple hundred dollars.

3D print one.

Well, well, well. Looky here. It appears that this may very well be the same little 15 tooth brass gear as used in the MD2 and MD3. Certainly there can't be anything special about it other than the length of the gear and shaft diameter. I wonder if it's just barely possible I can dig one up on the internet somewhere. Watch it turn out to be something you can get a bagful of for peanuts. I should be so lucky.

Im sure there is nothing special about that gear. There are hobby shops on line for robotics that sell assorted gears for peanuts by the bag full. Try looking at shops that sell ADRUINO stuff too?

Google SMALL PLASTIC GEARS

Once upon a time there was a company called SMALL PARTS. Im not sure if they are still in business.

Google SMALL PLASTIC GEARS

Once upon a time there was a company called SMALL PARTS. Im not sure if they are still in business.

I never bothered with gears in cameras and lenses so far, so I don not know. But I am not sure at all that japanese makers used a international standard gear shape. (Even the US and european gear shape is different...) And with high numbers any propriatory gear would not cost more. And even if the gear would be standard, the hub likely would be not.

I have repaired three Nikon MD-3 motor drives with the following gear. It works great, I used the brass gear, but there is a delrin gear also available.

https://shop.osorail.com/category.sc?categoryId=152

https://shop.osorail.com/category.sc?categoryId=152

Thank you for the link, although there were no photos of the gears. And I don't know enough about gears to pick it out. But I do believe the one I need is the same one as the MD3 one. So if I could kindly presume upon you to look on that site and tell me which one, I'd be appreciative. I hope we're talking about gears made to metric specs. Thank you.I have repaired three Nikon MD-3 motor drives with the following gear. It works great, I used the brass gear, but there is a delrin gear also available.

https://shop.osorail.com/category.sc?categoryId=152

Outside diameter; inner shaft diameter aka the bore; the height; number of gear teeth, mark one and count them; the pitch of the gear teeth.And I don't know enough about gears to pick it out

A gear tooth is (EDIT) a triangle, the angle and depth can vary, and the top can be rounded or pointed..

High School math will suffice even if its rusty.

Last edited:

Yikes, sounds like a time trap. Try using the camera without the winder until a simple solution presents itself.

I waited a long time for a cheapo ELW to come along with winder. I have the camera apart on the table now, headed into the reassembly phase. If I was to use the ELW without the winder, I could have had an EL an long time ago. When you have an ELW, then you use the winder. That's the rule. I'm not going through all this tedious repair work just to have half the camera. You should see the dent work I did on the top cover last night. Masterful. It's always satisfying to do such a good job on paintless dent removal.Yikes, sounds like a time trap. Try using the camera without the winder until a simple solution presents itself.

I have repaired three Nikon MD-3 motor drives with the following gear. It works great, I used the brass gear, but there is a delrin gear also available.

https://shop.osorail.com/category.sc?categoryId=152

Thank you. I thus stand corrected with my scepticism.

That is good news, as there may be be hope for other gear issues.

Outside diameter; inner shaft diameter aka the bore; the height; number of gear teeth, mark one and count them; the pitch of the gear teeth.

A gear tooth is two triangles back to back forming a wedge, the angle and depth can vary.

High School math will suffice even if its rusty.

A good tool to establish the right teeth is a gear-gauge. It is similar to a thread gauge.

This one is calibrated in "Module" as are the gears in that shop linked above.

https://www.fohrmann.com/de/zahnrad-modul-lehre-7-verschiedene-din-5480.html

I looked at the link and saw the correct one. Thank you. I'm going to but 3. ! each for my MD2, MD3, and AW1

and nobody, like, n o b o d y said "sover wong" yet?

http://soverf2repair.webs.com/MD2_MD3_gears.htm

http://soverf2repair.webs.com/MD2_MD3_gears.htm

Nylon gears are lighter and quieter in operation but not as durable over long periods of time.

Brass gears are heavier, louder in operation but very durable over long periods of time.

Be sure to lube the brass gear(s) well during assembly.

Brass gears are heavier, louder in operation but very durable over long periods of time.

Be sure to lube the brass gear(s) well during assembly.

Good Job, I'm too fumble fingered to tackle such a task. I did repair a Hassleblad grip the other day, had to make a custom machine screw, it turned out great. I do love the Nikon stuff. I have a couple MD2 motor drives, pretty neat!I waited a long time for a cheapo ELW to come along with winder. I have the camera apart on the table now, headed into the reassembly phase. If I was to use the ELW without the winder, I could have had an EL an long time ago. When you have an ELW, then you use the winder. That's the rule. I'm not going through all this tedious repair work just to have half the camera. You should see the dent work I did on the top cover last night. Masterful. It's always satisfying to do such a good job on paintless dent removal.

Best Regards Mike

Thank you for the link, although there were no photos of the gears. And I don't know enough about gears to pick it out. But I do believe the one I need is the same one as the MD3 one. So if I could kindly presume upon you to look on that site and tell me which one, I'd be appreciative. I hope we're talking about gears made to metric specs. Thank you.

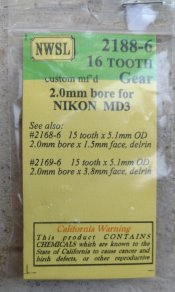

This is the one IP used for my MD-3

Mod 0.3 16T SGb. Found on Nikon MD3 camera. (1)

Well the gear came and it seems to work quite well. The attached photo is the little bag it came in. It says for MD3, but it fit right in on my Nikon/Nikkormat AW1. The old plastic gear had no set screw and neither did this brass replacement. Since the old gear was split, it slipped right off the motor shaft. And the new brass one slipped right on. If it's supposed to be a friction fit, there wasn't much friction as I was able to push it on the motor shaft with just my fingernails. I guess it's tight enough on its shaft because the winder now works and doesn't seem to have any slippage. Turned out to be a very easy repair. I'll tell you what though, a Nikkormat ELW winder is no bolt of lightning in its winding speed. I can manually wind it with the advance lever faster than the winder can wind. But it's still a pretty fun little camera. Right now all I have in the winder is cheap dollar store Sunbeam alkalines reading about 1.3 V. Maybe it's be a little snappier with fresh Duracells or something.

Attachments

I would remove the gear, coat the shaft with Locktite 242 Blue threadlocker and reassemble the gear. Let it sit until the threadlocker cures before putting into use. AA alkaline or carbon batteries that read 1.3V are ready fir the recycle bin.

I already tried to pry the gear up. Won't budge.As I was pushing it on with my fingernails, there came a point where I couldn't any more and had about another 1/16 left to go. So I gave it a couple light taps with the ball peen and a screwdriver. I think it's on pretty good. Maybe a small droplet of CA glue to seep in, but I'm not going to open it back up for that. If it starts to slip at some point, I'll know. As for putting the alkalines in the garbage, I put them in the charger.

Last edited:

Congratulations on your repair.

Likely tapered for a press fit, should be fine.I already tried to pry the gear up. Won't budge.As I was pushing it on with my fingernails, there came a point where I couldn't any more and had about another 1/16 left to go. So I gave it a couple light taps with the ball peen and a screwdriver.

I don't put them in the garbage. Local pickup has a Recycle bin for paper, cans, bottles. Batteries are left on top of the bin in a separate bag and they are handled separately.As for putting the alkalines in the garbage, I put them in the charger.

| Photrio.com contains affiliate links to products. We may receive a commission for purchases made through these links. To read our full affiliate disclosure statement please click Here. |

PHOTRIO PARTNERS EQUALLY FUNDING OUR COMMUNITY:  |