I was quite intimidated to go into this camera because of the name. Procrastination got the better of me and I'm glad it did. Rolleiflex is just a thing (a thing of beauty for sure), and things can be replaced.

Yep, it's a tool, made by humans. Humans put it together, humans can take it apart, that's my motto!! And I have a box full of cadaver cameras to prove it

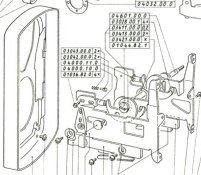

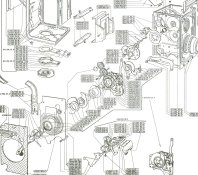

Rolleis were BUILT to be serviced. This is something that separates them from most other cameras. I like to point to the assorted service manuals for three different TLRs. The Yashicamats have two or so exploded drawings; I have never seen sign of any written directions from the factory. The Minolta Autocord has a 24 page service manual with drawings and written directions. The Rolleiflex has a 300+ page service manual with drawings, directions, lubrication schedules, etc.

And this matches my experience working on all three. I have come to dread working on YashicaMats in many ways. I think it was a forerunner of 'plug and play' systems: people installed parts, if it worked it went down the line and if it didn't work it went in the parts bin. Autocords are simpler than Rolleis, but also have fewer adjustment points. And Rolleis were made to be taken apart. The finish of parts also matches this- Yashica is rough, Minolta is competent, Rollei is smooth.

An interesting thing I've noticed with Rolleis: screws tend to be very specific for each assembly. Lens shroud screws aren't interchangeable with focus rail screws, or even side panel screws. On the wind mechanism, of the maybe 10 different screw uses, each one is unique. I think that this was more than a mechanical engineering issue. I think that this was a production/service issue so that you could assemble quickly and smoothly with less worry about using the wrong screw. All in all, more than most cameras, the Rollei parts tell you where they belong.

People are scared of Rolleis, but in practice they are easy to work on because they were made to be worked on. Industrial design and machining at its peak. You have some of the best machinist in the world talking to you, all you need to do is listen to the parts they made.