I picked up some Revere from B&S in Santa Fe 2 weeks ago. My initial tests were definitely underwhelming given my expectations based on Kerik's initial comments. Being out here in very dry New Mexico, I thought that lack of humidity might be the cause, but raising RH in my darkroom from 35% to 70% only made things worse.

I have tried several other variations as well:

- With and without Tween - with is better

- Both sides of the paper - back side is better

- Lightweight and Heavyweight versions - lightweight is better

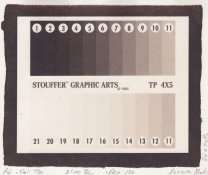

- Double coating - increase in Dmax from ~ 1.3 to ~1.4

- Brush and tube coating - no appreciable difference

Somewhere I had gotten the idea that this paper would not be buffered, but when I checked it with the pH pen I found it to be strongly alkaline. Acidification in oxalic acid helped slightly in the smoothness of the denser tones, but exaggerated an overall mottling/speckling like reported by Dave above. Increasing ambient humidity had a similar effect with regard to mottling.

Late last week I called Kerik to see if he had tried out the production run yet. He did some tests over the weekend and reported that he is getting results as good as with the pre-production samples that his initial report was based on. He also said that both are alkaline so I guess that eliminates a change in pH as the prime cause of (some of) our problems.

I also called Dana last week and he said that they had not yet tested the paper in-house. He said he would let me know how it was working for him but I have not yet heard back. I was going to wait until I had heard back from Dana before making any comments here, but since Dave is having the same problems that I'm having ....

Finally, as a control, I tested a known good piece of Platine side by side with the Revere to see if maybe the problems could be not caused by the paper but by something else. The Platine looks absolutely yummy. There is definitely something funky going on with the Revere, at least in my working environment.

On the plus side, I really like the texture of the paper surface, which reminds me of the Simili Japon that was my favorite while it worked.

~ Keith