Hunter_Compton

Subscriber

After a few years of good service, the frame counter spring in my Kodak Retina IIa (type 016) died. Disassembly of the winding lever showed that the small spring steel arm of the part broke off at its transition point where it bends to engage the frame counter ratchet.

Not wanting to seek out a parts camera and hope the frame counter spring was good, I opted to try repairing the existing part.

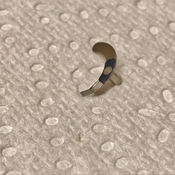

Here's the piece of the spring that broke off alongside my source of material for fabricating a repair. The dull coping saw blade is made of spring steel. I filed the teeth off and reduced the thickness to 0.008" to match the original.

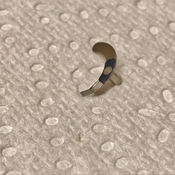

A small length was cut off and bent at about 45 degrees. I then soldered this to the inside of the remaining projection on the frame counter spring.

This ended up working quite well. I even eyeballed the dimensions close enough that I didn't have to do any filing of the finished part to get the finger to engage the ratchet properly. When reassembled it worked as good as a factory new part. I figured I'd post this here as this is a known issue with the Retina IIa, and this gives another option versus finding a replacement.

Not wanting to seek out a parts camera and hope the frame counter spring was good, I opted to try repairing the existing part.

Here's the piece of the spring that broke off alongside my source of material for fabricating a repair. The dull coping saw blade is made of spring steel. I filed the teeth off and reduced the thickness to 0.008" to match the original.

A small length was cut off and bent at about 45 degrees. I then soldered this to the inside of the remaining projection on the frame counter spring.

This ended up working quite well. I even eyeballed the dimensions close enough that I didn't have to do any filing of the finished part to get the finger to engage the ratchet properly. When reassembled it worked as good as a factory new part. I figured I'd post this here as this is a known issue with the Retina IIa, and this gives another option versus finding a replacement.