X. Phot.

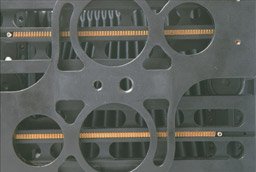

I've got a Pressman Model D that I would like to reduce in weight, as much as possible. I recall seeing a press camera that had been drilled to reduce it's weight. The drill pattern used was somewhat fancy. Does anybody have an example of this? Thanks in advance.

Last edited by a moderator: