If you've ever looked at your pinhole through a microscope, you've probably seen just how excessive the concern about "optimal" can be. Getting the hole to be clean and free of metal junk when it is new is a real challenge, and keeping it clean afterward isn't much easier. You could have a "perfect" pinhole and still get very disappointing results.

-

Welcome to Photrio!Registration is fast and free. Join today to unlock search, see fewer ads, and access all forum features.Click here to sign up

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pinhole size and distance

-

A

- Thread starter Darkroom317

- Start date

Recent Classifieds

-

Sold Intrepid 4x5 Black Edition

- Started by Jessxi

-

For Sale 35mm black and white film. 17 rolls

- Started by Simon Benton

-

For Sale STEARMAN SP-8x10+ DAYLIGHT SHEET FILM PROCESSING SYSTEM.

- Started by Simon Benton

-

For Sale Original Canon F1 professional camera, two lenses.

- Started by summicron1

-

Sold Phochron XA shutter tester

- Started by OrientPoint

Forum statistics

Thomas Bertilsson

Member

How do you recommend keeping a pinhole clean?

- Thomas

- Thomas

If you've ever looked at your pinhole through a microscope, you've probably seen just how excessive the concern about "optimal" can be. Getting the hole to be clean and free of metal junk when it is new is a real challenge, and keeping it clean afterward isn't much easier. You could have a "perfect" pinhole and still get very disappointing results.

Usually, if I'm not in my studio, I just blow on the thing really hard from both sides. This isn't really good enough but it makes me feel better. I've washed them, blown them with compressed air, and gently cleaned them with a needle. The last mentioned requires a very delicate touch, but that is the way I get them clean when I make them and I've had a lot of practice. As I've grown older, though, everything about making and maintaining pinholes has become much more difficult as my eyes become less reliable and touch loses some of its steadiness.

I have to wonder about using some sort of sticky stuff to collect transient particles, a kneaded eraser might work (the kind that we use in charcoal drawing).

Maybe some sort of electrostatic device could work; I have one of those gizmos that labs used to clean negatives, but I haven't yet tried running a pinhole through it.

It's sort of impractical to carry an air compressor around all the time. Another idea that seems promising would be to carry a small graduated tube to blow through, concentrating a stream of air. Washing in water is practical, but the hole needs to be dry; a drop of water becomes a lens.

Regardless of what you do to clean a pinhole, it is important to be able to observe its condition. I use a 50x projection microscope to see what's going on if I have it available. Out there when working, a pocket microscope can be helpful if I remember to take it with me. A loupe or magnifying glass doesn't magnify enough.

Or, of course, you can just live with what you get. I think the most important thing is to start out with a clean pinhole and try whatever you think might work when you are using it. If the hole has ragged metal left in it when it's made, it will affect both exposure and image quality.

Now, I must confess that I really like a "sharp" pinhole image, to the point where my pinholes have been criticized as "too damn sharp". The quality possible in a pinhole image can be really amazing. While they don't have that kind of sharpness that lenses can produce, there is a potential for sharpness embedded in softness, if you can visualize what I mean. It's hard to describe.

I have to wonder about using some sort of sticky stuff to collect transient particles, a kneaded eraser might work (the kind that we use in charcoal drawing).

Maybe some sort of electrostatic device could work; I have one of those gizmos that labs used to clean negatives, but I haven't yet tried running a pinhole through it.

It's sort of impractical to carry an air compressor around all the time. Another idea that seems promising would be to carry a small graduated tube to blow through, concentrating a stream of air. Washing in water is practical, but the hole needs to be dry; a drop of water becomes a lens.

Regardless of what you do to clean a pinhole, it is important to be able to observe its condition. I use a 50x projection microscope to see what's going on if I have it available. Out there when working, a pocket microscope can be helpful if I remember to take it with me. A loupe or magnifying glass doesn't magnify enough.

Or, of course, you can just live with what you get. I think the most important thing is to start out with a clean pinhole and try whatever you think might work when you are using it. If the hole has ragged metal left in it when it's made, it will affect both exposure and image quality.

Now, I must confess that I really like a "sharp" pinhole image, to the point where my pinholes have been criticized as "too damn sharp". The quality possible in a pinhole image can be really amazing. While they don't have that kind of sharpness that lenses can produce, there is a potential for sharpness embedded in softness, if you can visualize what I mean. It's hard to describe.

Thomas Bertilsson

Member

Interesting. Thanks for your reply.

The pinhole camera I use has a very good pinhole. It's sharp and clean, and I'm amazed at how nice the prints look when I make the most use of the contrast available in the paper. Even more so than with lens photography, I find that getting the negative 'just right' is even more important, because I feel like I rely on tonal values for sharpness.

I haven't had to clean my pinhole yet, after almost two years of using it. Perhaps it's time to check it with a microscope!

Thanks again for your advice.

The pinhole camera I use has a very good pinhole. It's sharp and clean, and I'm amazed at how nice the prints look when I make the most use of the contrast available in the paper. Even more so than with lens photography, I find that getting the negative 'just right' is even more important, because I feel like I rely on tonal values for sharpness.

I haven't had to clean my pinhole yet, after almost two years of using it. Perhaps it's time to check it with a microscope!

Thanks again for your advice.

If you've ever looked at your pinhole through a microscope, you've probably seen just how excessive the concern about "optimal" can be. Getting the hole to be clean and free of metal junk when it is new is a real challenge, and keeping it clean afterward isn't much easier. You could have a "perfect" pinhole and still get very disappointing results.

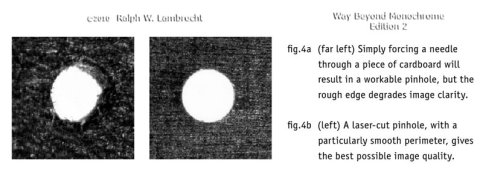

I have. Attached is a laser-cut pinhole and it's comparison with a crude needle-through-cardboard job.

Attachments

- Joined

- Jan 26, 2007

- Messages

- 1,159

- Format

- Medium Format

Thomas, all my pinholes have red 25's permanently mounted. I initially put them there because I like sky images and cloud motion, and the reds really darken the sky and add a couple stops exposure. But the only time the hole is exposed is when loading or unloading film in the darkroom, so I have seen no need to clean them.

The reds appeared to improve "sharpness" compared to unfiltered, by restricting other wavelenghts (so I am told). What really helped was smoking the holes over an oil lamp, then recapitulating them with the needle and checking under the scope. Where there were microscopic metal shards, they were filled in with the soot and the holes now appear laser drilled. What this did to the effective thickness of the hole, I don't know. But it appears to have helped.

I have a dozen negs I'm working on now, and hope to get some stuff up soon. 'Tis the season to p-hole!

The reds appeared to improve "sharpness" compared to unfiltered, by restricting other wavelenghts (so I am told). What really helped was smoking the holes over an oil lamp, then recapitulating them with the needle and checking under the scope. Where there were microscopic metal shards, they were filled in with the soot and the holes now appear laser drilled. What this did to the effective thickness of the hole, I don't know. But it appears to have helped.

I have a dozen negs I'm working on now, and hope to get some stuff up soon. 'Tis the season to p-hole!

As far as the material for my pinhole I have chosen aluminum. The pinhole is to be created with an engraving laser that I use at work

Thomas Bertilsson

Member

Rich,

With pinhole having pretty much infinite depth of field, I have always been wary of using filters with them. But I might purchase some gel filters and give it a go. I'd probably use an orange filter, though.

Thanks for the tip.

- Thomas

With pinhole having pretty much infinite depth of field, I have always been wary of using filters with them. But I might purchase some gel filters and give it a go. I'd probably use an orange filter, though.

Thanks for the tip.

- Thomas

Thomas, all my pinholes have red 25's permanently mounted. I initially put them there because I like sky images and cloud motion, and the reds really darken the sky and add a couple stops exposure. But the only time the hole is exposed is when loading or unloading film in the darkroom, so I have seen no need to clean them.

The reds appeared to improve "sharpness" compared to unfiltered, by restricting other wavelenghts (so I am told). What really helped was smoking the holes over an oil lamp, then recapitulating them with the needle and checking under the scope. Where there were microscopic metal shards, they were filled in with the soot and the holes now appear laser drilled. What this did to the effective thickness of the hole, I don't know. But it appears to have helped.

I have a dozen negs I'm working on now, and hope to get some stuff up soon. 'Tis the season to p-hole!

- Joined

- Jan 26, 2007

- Messages

- 1,159

- Format

- Medium Format

Darkroom, the best material I have found for the holes is stainless steel dental matrix bands. Any dental office would be glad to hand over a couple, they are dirt cheap. The "dead soft" bands I believe are .0015" thick, which is hard to beat. They sand beautifully, and you can probably make four holes out of one band.

Maybe with your engraving laser it's not necessary or helpful to smoke them.

Maybe with your engraving laser it's not necessary or helpful to smoke them.

My material of choice is pure silver, rolled to .003. I make the hole too big, and with a polished hammer and anvil, I thin and expand the metal with the hole in it. This will make the hole too small, so I repeat this routine over and over, bringing the hole gradually to correct size. There are episodes of dressing, as needed, with a fine jeweler's file. This results in a domed, work hardened square of silver of unknown, but extremely small thickness. I wouldn't blacken with smoke, because of the change in dimension as well as it's susceptibility to rubbing off. Instead, I simply selenium tone the silver, which doesn't affect the dimension. Although it isn't "perfectly" black, the silver, over time, will continue to darken. You know, tarnish.

I am very leery of laser drilled holes, because they will inevitably be tubes. This would be ok, if the material is thin enough. I believe the best holes to be hand finished, and as close to knife edged as possible. It is handy to have had some jewelry experience and facility in working with metal.

About the filter thing, I more or less gave up on it. Eric Renner had suggested I research it and contribute my findings to I guess it must have been the second edition of his book. When I put the filter on - this was gels - every little thing that could get on the filter produced an ugly spot in the negative. With 8x10 film, that was pretty expensive. Of course, doing this out on the desert didn't help. I got to thinking that the solution to the problem would be to fill the pinhole with gel, so that any garbage would be both less likely to be there and couldn't produce the kind of problem I was getting.

I am very leery of laser drilled holes, because they will inevitably be tubes. This would be ok, if the material is thin enough. I believe the best holes to be hand finished, and as close to knife edged as possible. It is handy to have had some jewelry experience and facility in working with metal.

About the filter thing, I more or less gave up on it. Eric Renner had suggested I research it and contribute my findings to I guess it must have been the second edition of his book. When I put the filter on - this was gels - every little thing that could get on the filter produced an ugly spot in the negative. With 8x10 film, that was pretty expensive. Of course, doing this out on the desert didn't help. I got to thinking that the solution to the problem would be to fill the pinhole with gel, so that any garbage would be both less likely to be there and couldn't produce the kind of problem I was getting.

Rich,

With pinhole having pretty much infinite depth of field, I have always been wary of using filters with them. But I might purchase some gel filters and give it a go. I'd probably use an orange filter, though.

Thanks for the tip.

- Thomas

One thing working for us with filters is that when anything is closer to the hole (in front) than the FL, it is enlarged and progressively less sharp. If it could be close enough to the hole, the image of it would enlarge to the point where it would be so nebulous that it would have very little if any visible effect on the image.

I've ran into some sharpness issues. I took the ground glass from RB67 and checked my pinhole camera, nothing appears to be even close to sharp. Is this a good indicator? Do I need to make the pinhole smaller, it is currently .4mm.

A glass filter (gel filters are lousy for any photography) can be successfully employed with no adverse effect on the image by mounting it behind the pinhole, edges masked. It's when you put a filter in front of a pinhole that image quality dramatically suffers.

It would be helpful to know your pinhole to focus plane distance, and also, if you can, to see an image of you pinhole made at about fifty to 100 x or so. Smaller is not generally the answer.

Maybe you are thinking that a pinhole image should compete with a lens on the lens' terms. It can't, and ought not be expected to. If it did, why bother? The parameters are different. Lenses and pinholes are NOT the same thing, and what they do is different. You can have a sharp image from a pinhole, but it doesn't look like a sharp image made with a lens.

I have a pinhole that I use in my Leicas, but I use it when I don't want to do what Leitz likes to see! I sent one to Germany with a friend who was visiting Leitz, and was very unhappy when he told me he was too "chicken" to show it to them. Bummer. I suspect someone would have been interested. He said they seemed to like beer a lot. But he kept the body cap with the pinhole mounted in it in his pocket!

You might not like what the pinhole gives you. Or, you might not like it NOW, but be sure to look again in a few years. We change, too. I'd never have accepted the kind of image a pinhole makes had I started making them prior to ten years into my career. Really. But now I love it, IF it meets my rather stringent standards.

Maybe you are thinking that a pinhole image should compete with a lens on the lens' terms. It can't, and ought not be expected to. If it did, why bother? The parameters are different. Lenses and pinholes are NOT the same thing, and what they do is different. You can have a sharp image from a pinhole, but it doesn't look like a sharp image made with a lens.

I have a pinhole that I use in my Leicas, but I use it when I don't want to do what Leitz likes to see! I sent one to Germany with a friend who was visiting Leitz, and was very unhappy when he told me he was too "chicken" to show it to them. Bummer. I suspect someone would have been interested. He said they seemed to like beer a lot. But he kept the body cap with the pinhole mounted in it in his pocket!

You might not like what the pinhole gives you. Or, you might not like it NOW, but be sure to look again in a few years. We change, too. I'd never have accepted the kind of image a pinhole makes had I started making them prior to ten years into my career. Really. But now I love it, IF it meets my rather stringent standards.

A glass filter (gel filters are lousy for any photography) can be successfully employed with no adverse effect on the image by mounting it behind the pinhole, edges masked. It's when you put a filter in front of a pinhole that image quality dramatically suffers.

It will affect the image either way, it depends on how close to the hole it is located. Yes, it would probably be different, but not that much. Glass filters would be just as bad or worse, because they have greater thickness. It's not imperfections in the surface here, that are the problem. It's what is on the surface and how far it is from the hole.

I have used gel filters for many, many years and they work just fine if you are careful to use them as they must be used. Best, of course, is to unscrew one of the elements of a lens and put a filter cut in a circle to size inside, then screw it back in. I have several lenses that have permanent gels installed. I have used my 8x10 Master View as an "ensmaller" to reduce an 11x14 negative, much in demand, itself made with a set of gel filters. It was an image of a theater interior. I shot color paper in the 8x10 for the client to gift it's board members when they retired. So, there were several trips through gels, both in shooting and in printing with no visible effects at all. Now, I've been doing this for 45 years professionally. If there were a problem, I'd have seen it.

Perhaps you had a bad experience? How can you be sure that the gels were the problem?

Lee L

Member

- Joined

- Nov 17, 2004

- Messages

- 3,288

- Format

- Multi Format

Before digital, gel filters were the de facto standard and first choice for 4x5 and larger format studio photography. In large format they are often used in a filter holder on the back of the lens, protected inside the camera bellows. It was common to stack up to three filters for color correction on E6 film. Gels have excellent optical qualities, even compared to the best glass filters.... gel filters are lousy for any photography...

I would agree that gels are not so great in front of the lens for field work, but only because of their more fragile nature and difficulty in cleaning them, not because of optical shortcomings.

Lee

Maybe you are thinking that a pinhole image should compete with a lens on the lens' terms. It can't, and ought not be expected to. If it did, why bother? The parameters are different. Lenses and pinholes are NOT the same thing, and what they do is different. You can have a sharp image from a pinhole, but it doesn't look like a sharp image made with a lens.

No, I certainly do not expect it to compete with a lens. If I wanted an image like that, I would use a regular camera and lens. The distance is 3 inches.

It may indeed be sharp. Likely I will just sacrifice a roll of film and see how it works. As expected it is really dark therefore I may not be seeing the image that well.

- Joined

- Sep 9, 2006

- Messages

- 94

- Format

- Medium Format

Details ....

I'm a little late to this discusion but wanted to chime in with my observation about what Ralph has stated and illustrated well with his diagram - that pinhole size affects angle of view.

As far as it has been illustrated the diagram would serve to support the assertion that size does in fact affect angle of view. However .... it does not.

The detail omitted is the film size. The diagram, if it is to be made more complete would show the film. Draw a same size, lets say one inch line under each of the diagrams. This would represent the boundary of your film size and then we will see that in the first expample if the film is far enough back a too small hole would cause dramatic vignetting where the light does not reach directly but only through bouncing around. If the second size is taken as correct and being larger enables light traveling in a straight line to reach the corners then a larger hole will only have more of the light hit areas inside the camera that are the sides, not on the film but if you measure the angle of view, that is to say the angle of view which the film records - then it will be identical to the middle (or optimal) pinhole size.

Ergo ... pinhole size does NOT affect angle of view. Not once the defining boundaries, that is to say the distance from the film plane and the size of the pinhole also include the third variable - the size of the film.

So a pinhole can be too small in relation to other factors and cause vignetting but larger than optimal will only degrade the quality, but not change the angel of view.

Details, details!

I'm a little late to this discusion but wanted to chime in with my observation about what Ralph has stated and illustrated well with his diagram - that pinhole size affects angle of view.

As far as it has been illustrated the diagram would serve to support the assertion that size does in fact affect angle of view. However .... it does not.

The detail omitted is the film size. The diagram, if it is to be made more complete would show the film. Draw a same size, lets say one inch line under each of the diagrams. This would represent the boundary of your film size and then we will see that in the first expample if the film is far enough back a too small hole would cause dramatic vignetting where the light does not reach directly but only through bouncing around. If the second size is taken as correct and being larger enables light traveling in a straight line to reach the corners then a larger hole will only have more of the light hit areas inside the camera that are the sides, not on the film but if you measure the angle of view, that is to say the angle of view which the film records - then it will be identical to the middle (or optimal) pinhole size.

Ergo ... pinhole size does NOT affect angle of view. Not once the defining boundaries, that is to say the distance from the film plane and the size of the pinhole also include the third variable - the size of the film.

So a pinhole can be too small in relation to other factors and cause vignetting but larger than optimal will only degrade the quality, but not change the angel of view.

Details, details!

- Darkroom317

- Deleted

Pavel

Did I say pinhole size affects angle of view somewhere?

Did I say pinhole size affects angle of view somewhere?

- Joined

- Sep 9, 2006

- Messages

- 94

- Format

- Medium Format

Pavel

Did I say pinhole size affects angle of view somewhere?

No, you said pinhole thickness, not size - and that is what I mean to type in my response - sorry. But it is the same difference. As the light rays move in a straight line the angle of view is determined by the distance and size of the film. Only. In the diagram you show, light will correctly illuminate a wider field in the last example - but it is immaterial as it will miss the film and thus not affect the angle of view.

Lastly, the thickness has a simple geometric relationship to size - so whether the widest angle is due to size or thickness ... it really does not matter and thus neither does the distinction.

(None of this is very important - I almost wish I hadn't put in my two cents worth

)

)... In the diagram you show, light will correctly illuminate a wider field in the last example - but it is immaterial as it will miss the film and thus not affect the angle of view. ...

The only point of the diagram is to show that too thick of a pinhole material can cause vignetting. The caption states:

The pinhole material thickness limits the angle of coverage. Thick materials may reduce the angle of view, and the pinhole will no longer fill the entire negative format.

Sorry, if I didn't make this sufficiently clear.

Many formulae for optimum pinhole diameters are most valid for on-axis image sharpness. However, both sharpness and illumination dramatically decrease near the edges of ultra wide angle coverage. A somewhat larger than normal pinhole can provide some gain in corner sharpness at the expense of on-axis performance. 30 years ago I improvised a camera to test this. A rough graph of the results is attached. Also, in regard to filters, since the sharpness of pinhole photography is partly dependent on the wavelength of light, there is a very slight gain in sharpness by using blue sensitive film or a blue filter over using a red filter. This, too, has been verified by experimentation, but I don't have the results available.

Attachments

Jim

Thanks for this graph. It shows extremely valuable data.

However, before this discussion get too confusing, we must make a difference between resolution and contrast, and concentrate on perceived sharpness. There are two equations for the optimal pinhole diameter: one for max resolution and one for max contrast.

While a smaller hole will give more resolution (up to a point) a slightly larger hole will provide more contrast and perceived sharpness. The attached MTF shows that and verifies your statement.

Normally people subconsciously prefer contrast over resolution (high-resolution images are often too soft to be valued as sharp), and therefore, the optimum pinhole diameter based on contrast (and not resolution) is preferred.

Thanks for this graph. It shows extremely valuable data.

However, before this discussion get too confusing, we must make a difference between resolution and contrast, and concentrate on perceived sharpness. There are two equations for the optimal pinhole diameter: one for max resolution and one for max contrast.

While a smaller hole will give more resolution (up to a point) a slightly larger hole will provide more contrast and perceived sharpness. The attached MTF shows that and verifies your statement.

Normally people subconsciously prefer contrast over resolution (high-resolution images are often too soft to be valued as sharp), and therefore, the optimum pinhole diameter based on contrast (and not resolution) is preferred.

Attachments

| Photrio.com contains affiliate links to products. We may receive a commission for purchases made through these links. To read our full affiliate disclosure statement please click Here. |

PHOTRIO PARTNERS EQUALLY FUNDING OUR COMMUNITY:  |