CONCLUSIONS - Long term stability of Pt/Pd prints on paper

Hello all,

I had planned to do this for a while. Since we have drifted a bit off of the main topic of the thread, I thought it wise to summarize my main conclusions from all I read up to know, and the contributions by others, with a special thanks to Mike Ware and Loris. I will also try to include some of the sources and scientific literature links I posted earlier in the thread. Just be aware that the content and some of the chemistry may be hard to understand, as some of the original scientific articles are quite complicated.

*** CONCLUSIONS: ***

- Despite the noble metals themselves being virtually indestructible (only concentrated hydrochloric or nitric acid will dissolve them), both true Platinotypes (100% Pt), Palladiotypes (100% Pd) and mixtures thereof,

can suffer from archival permanence or longevity issues. The main issue is not with the metals and image itself, but with threads to the

paper base.

- There are

four main threads to Platinum prints, and

three to Palladium prints, the difference caused by the much lesser catalytic activity of Palladium:

These are:

*

1) Acidification of the paper through the catalytic activity of Platinum, causing embrittlement of the paper. The catalyic activity of Platinum causes air born SO2 gas to be converted to SO3 and ultimately sulphuric acid (H2SO4) (See Mike's comments (there was a url link here which no longer exists) and in his

"Chrysotype: Photography in Nanoparticle Gold" article). Acidification leads to the breakdown of cellulose, as it splits the chains and causes depolymerization. Cellulose is the main component of wood and paper.

NOTE: this first issue is virtually absent in 100% Palladium prints, due to the much lesser catalytic activity for this reaction, if at all.

*

2) Breakdown of the cellulose in the paper base of a Pt/Pd print caused by Hydroxyl radical formation as a consequence of retained / uncleared Iron (Fe2+ or Fe3+ cations).

The process behind this is about the following (from

this article):

Fe2+ + O2 + H+ --> Fe3+ + HOO•

Fe3+ + HOO• + H+ --> H2O2

Fe2+ + H2O2 --> Fe3+ + OH- + OH•

OH• + Cellulose --> depolymerisation

Where OH• is a highly reactive Hydroxyl radical, as you can see created from the remaining iron in the print. Paper is mainly cellulose, and depolymerisation means the chains of cellulose are broken down in smaller pieces, causing embrittlement of the paper.

This is

not a trivial issue. There are quite a lot of historical examples of retained Iron. In fact, the

Getty Conservation Institute, states that

all of the Iron based process prints (Pt/Pd, VanDyke etc.) they investigated up to now using advanced X-ray Fluorescence (XRF) techniques,

showed some amount of residual retained Iron, even if very good practices were employed for clearing and washing. However, very tiny amounts of retained Iron will probably

not pose a major thread to longevity of the prints.

*

3) Discolouring of the paper base by formation of oxidized Iron (essentially "rust") causing yellow or even dark red stains. The Getty Conservation Institute has

witnessed Platinum prints with dark red highlights due to fully oxidized Iron.

*

4) Discolouring of the paper base by discolouring and break down of the paper fibres themselves. This will mainly occur with low grade lignin containing papers made of (purified) wood pulp, as lignin is even capable of autooxidation (reaction with Oxygen in the air, see "

Dead Link Removed"). However, it is likely that retained Iron will or may cause similar issues even on high grade 100% cotton rag paper, via the reaction described in issue 2).

Nonetheless, use of high quality 100% cotton rag paper - so paper made of cotton instead of wood - should provide good chances for long term survival of the print, since this kind of paper is of a very high almost pure cellulose content. Luckily, this is already common practice among Pt/Pd printers and recommended everywhere.

This reaction is probably also responsible for the

sometimes witnessed "image offsetting" onto cover paper seen with some Pt/Pd prints, whereby a mirror image becomes visible on the cover paper. See Mike Ware's remark below:

"'Image offsetting' by platinotypes is a well-known and characteristic effect, as illustrated by Jim Reilly and Taylor Whitney. It could be due to two things: the catalytic acid production diffusing across and degrading the opposite contacting sheet, or even to a more direct surface catalysis of the oxidative degradation by air of the polyphenolic lignin macromolecules in some wood-based papers, giving rise to quinoid structures with typical yellow-brown chromophores (same thing that causes colour of oxidised hydroquinone developers, and yellowing of newsprint). There should have been some research on this by now, but I don't have the infra-red instrumentation needed."

And another example of this:

*** WHAT CAN BE DONE TO PREVENT ALL THIS? ***

You may wonder what can be done to prevent all this. Well, the following things may be of help:

-

As said, only use highest quality 100% cotton rag paper, as it is one the most durable forms of paper with a very pure cellulose content and thus practically lignin free. Cotton rag documents have survived from the middle ages in remarkably good condition...

-

Frame all of your Pt/Pd prints behind glass, especially 100% Platinum prints. Although it is probably very tempting to have a matt print like Pt/Pd framed without glass, it will pose a long term thread. Framing isolates the Pt/Pd print from harmful gasses, especially the sulphurdioxide (SO2) that may be catalyzed by Platinum to harmful sulphuric acid.

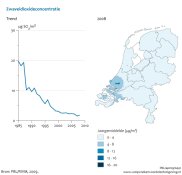

Luckily, SO2 emissions have gone down considerably over the past 20 years or so in the West (see my previous post above), meaning current conditions are unlike the

Victorian industrial age smog ridden cities (or

as recent as 1952 London), where many of the most severely affected Pt/Pd prints might date from. Still, we are not down to pre-industrial age clean air, and situations in some parts of the world are undoubtedly still bad.

-

Print 100% Palladium prints. This is only a partial solution, but since Palladium seems not to facilitate the catalyst conversion of SO2 to sulphuric acid, you will have reduced the chances of serious acidification as per described issue 1), although this is by no means a guarantee that no acidification at all will take place in the very long run, just that it will be much slower. CalciumCarbonate containing papers will reduce ill effects as well, by providing an alkaline buffer.

-

Employ the best clearing and washing techniques. Clearing in Pt/Pd printing, but also other Iron based processes like VanDyke Brown, removes the Iron sensitizer after exposure. This is a

vital step in the processing of Pt/Pd prints, especially for the long term survival of the print. Any retained Iron in the print may cause harm, although full removal of all iron is probably impossible (see remarks above), but safe levels are obtainable.

A good recommendation is the process described by Mike Ware in

this article:

Chemicals required for the Processing Solutions

• Ethylenediaminetetraacetic acid disodium salt, Na2Edta (pH 3-4)

• Ethylenediaminetetraacetic acid tetrasodium salt, Na4Edta (pH 9)

• Kodak 'Hypoclear' powder or sodium metabisulphite or sulphite

1 Disodium Edta (5% w/v) 10 mins

2 Rinse in water half min

3 Kodak Hypo Clearing Agent (working) 10 mins

4 Rinse in water half min

5 Tetrasodium Edta(5% w/v) 10 mins

6 Wash in running water minimum 30 mins

Please note though:

* It is of vital importance

to wash out all EDTA in the final washing cycle. EDTA is what is called a "chelating agent", it binds with the Iron (both Fe2+ and Fe3+) as present in the sensitizers, and forms rather soluble complexes that can be washed out. However, EDTA-Iron complexes, can

still induce Hydroxyl radical formation as described in issue 2), and hence may still cause damage if left in the paper. It is therefore vital to properly wash the prints and remove all complexed Iron/EDTA.

* All chelators like EDTA, and the in paper conservation world used Calcium- or MagnesiumPhytate chelators, preferentially complex with Fe2+. In addition, Fe3+ can form some less soluble compounds compared to Fe2+ and probably binds to the cellulose fibres. See remark below by Mike Ware regarding Fe3+ cations and it's lesser solubility compared to Fe2+:

"That may be because it's quite strongly bound to the cellulose via vicinal -OH groups, - or if Fe(III) hydrolysis has proceeded very far (a complex process) it may be macromolecular "hydrated ferric oxide" physically trapped in the cellulose microfibrils. Eventually it turns into the highly insoluble mineral, Goethite FeO(OH). Any, all, or none of these hypotheses may be correct!"

This all means that if any Iron is left in the print after proper clearing and washing, it is most likely Fe3+ species.

-

To ensure proper removal of Fe3+ a SodiumDithionite/EDTA bath might used. SodiumDithionite is a

reducing agent with a neutral pH, that will convert any Fe3+ to Fe2+, allowing it to be more easily washed out together with the EDTA (See

"A Conservation Treatment to Remove Residual Iron from Platinum Prints", and the short reference to the function of SodiumDithionite on the Ink Corrosion website

here).

- Use Bathophenanthroline Indicator Paper for testing for remaining Fe2+ (will not detect Fe3+) and thus for effective clearing in Platino/Palladiotypes. These indicator strips are used in the paper conservator world, and it seems they might potentially be a valuable new instrument for Pt/Pd printers. They seem to be very sensitive, capable of detecting just 1ppm (part per million) Iron according to the page

here.

The usage of Bathophenanthroline Indicator Paper is described in

this PDF document on the

Iron Gall Ink Corrosion website.

They can be bought at:

http://www.preservationequipment.com called "Iron Gall Ink Test Paper":

http://www.preservationequipment.co...ials/Other-Materials/Iron-Gall-Ink-Test-Paper

This test could serve as a Pt/Pd equivalent of a "residual-silver" test as employed by traditional silver gelatine printers for testing of adequate fixing of silverhalides from silver gelatine papers.

NOTE1: Since the test strips only detect free Fe2+ cations, not free Fe3+, use of a SodiumDithionite bath as described before might be good to ensure as much as possible conversion of the Fe3+ to Fe2+ cations, although according to Mike Ware in

this article, the SodiumSulphite or Hypo Clearing Agent, will serve to this purpose as well, although maybe not as effective as SodiumDithionite:

"Clearing of the residual iron compounds from the paper is improved by immersion next in a bath of Kodak Hypoclearing Agent interposed between the two Edta baths; alternatively a solution of sodium sulphite can be used. The inorganic sulphite in this tends to reduce any residual iron(III) to iron(II) which is then removed in the final tetrasodium Edta bath; the advantage is that these last two baths have a high pH (ca. 9) which is optimum for complexation of iron(II) and leaves the paper in a beneficial alkaline condition. The wet-processing sequence is summarised below."

NOTE2: Bathophenanthroline Indicator Paper may also be of use to other iron-based alternative processes, like VanDyke Brown, for the same purpose.

-

There may be a small case for a CalciumPhytate or MagnesiumPhytate treatment as an alternative to EDTA, or as for example the second bath after a first EDTA clearing bath. CalciumPhytate and MagnesiumPhytate have been used in the paper conservator world (See here for

CalciumPhytate or

here for MagnesiumPhytate) to remove free destructive Iron from Iron Gall ink written documents. Both leave, when properly executed, the paper at very favourable pH of about neutral, and the working solutions themselves are close to neutral. In addition,

Iron/Phytate complexes seem to be almost inert, meaning any complex left in the paper, is pretty harmless. On the contrary of all this, the treatment with Phytate may be a bit more laborious, and Iron/Phytate may be less soluble and hence more difficult to wash out compared to Iron/EDTA complexes.

Detailed instructions for preparing and using CalciumPhytate can be found on the

Ink Corrosion website.

Marco

Scale is valid for moderate central or northern European climates, but I guess it will work in other wetter climates as well, although the lichen species may or will be different.

Scale is valid for moderate central or northern European climates, but I guess it will work in other wetter climates as well, although the lichen species may or will be different. of the Lichen Scale is not mentioned on the chart...

of the Lichen Scale is not mentioned on the chart...  It looks likely though it is indeed a daily maximum average for a certain number of days per year, if compared to the norm levels I have included below.

It looks likely though it is indeed a daily maximum average for a certain number of days per year, if compared to the norm levels I have included below.